-

Posts

2,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jim Coke

-

Greetings Dave, My set ups are different. If you are going to use the HF planishing hammer I would first suggest an in line foot control air switch. To stop the chisels from turning I would make a steady hold for vise grip and use the leather to hold the chisel from turning. You can grind the chisel square under the leather contact point and for sure it won’t rotate. I hope this helps . Forge on and make beautiful things Jim

-

Greetings Dave, Yep me again... I did a lot of chase and repousse work .. I designed a special machine that works great. The air hammer is rigid mounted but the work table is hydraulic and movable by the foot pedal. I can control the chisel depth and air hammer speed at the same time.. The big wheel adjust the table up and down 6 inches and the foot pedal dual control 1/2 inch. I have also a old air hammer part set up to use chisels in my fly press that accepts air chisels. Lots of tools for different applications. The nice part is adjustable depth for different base media. Forge on and make beautiful things Jim

-

Greetings Das, Ya gunna need a bigger trailer.. I used to sneak tons of good stuff home like you than my wife figured out that I was telling a white lie when I told her that I had that stuff for years. Whoops. Have fun.. Forge on and make beautiful things Jim

-

Found a new replacement anvil!

Jim Coke replied to windancer's topic in Anvils, Swage Blocks, and Mandrels

Greetings Dave, Your more than welcome. Enjoy ... Forge on and make beautiful things Jim -

Greetings Nick. A few small leaks would not be a problem at all . The volume of hot gasses going up creates a vacuum that would suck air in rather than exhaust out.. Another seam for sheet metal is called a drive . Google it.. HAVE FUN AND GOOD LUCK Forge on and make beautiful things Jim

-

Bar Bender for a vice using old sockets

Jim Coke replied to SLS's topic in Tools, general discussion

Greetings SLS, Yet another way to make a bending tool.. This way you just make the adjustments pinching the tool in the vise. Been using it for years. Easy to make.. Forge on and make beautiful things Jim- 3 replies

-

- strap bender

- strip bender

-

(and 1 more)

Tagged with:

-

JHCC. On my list..

-

Greetings Eophex, Another alternative to a cone is a flat spiral. Pictures below are 1/2 square bar 24 inches long no welds or interruptions . I did this one as a challenge but you get the idea on the spiral. Have fun . Forge on and make beautiful things Jim

-

Greetings Eric, Pictures of your blowers might help.. I might just have a stand. Forge on and make beautiful things Jim

-

Greetings Eseemann, I have been using air chisels for blacksmith work for years . Most are S7 or close to it. Granted most of the work I do with them is cold but they work well with hot work . As far as hardness any chisel that you use with hot iron won’t be hard long. If you file test a new air chisel you will find that they aren’t that hard to start with. The biggest problem with hot work is holding your stock and not loosing heat on a sturdy base. Not much time is saved using them on hot metal unless you have a large number of pieces to do. Experiment and have fun. Forge on and make beautiful things Jim

-

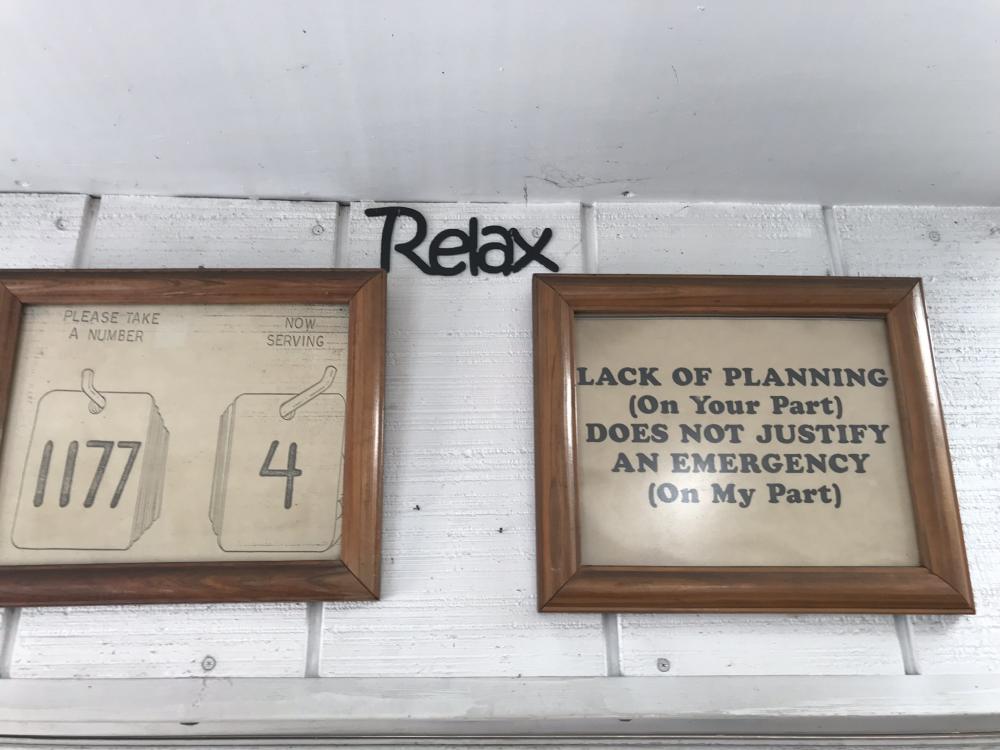

Signs /Pictures in your shop

Jim Coke replied to Jim Coke's topic in Blacksmithing, General Discussion

Another favorite on the wall behind my blower. Note the fine brass handle.. A wonderful birthday gift from Black Frog. Jim -

My beautiful Trenton.. Originally purchased by a chemical company in Detroit in the late 40s . Sold at auction and purchased by a picker who sold it to his friend. I went to see it and the new owner said the only way I would ever end up with it was over his dead body. Two years later I got a call from his widow. 300 pounds and the original factory stand . This Trenton is a belt line welded one that the top half is all tool steel. Bought it for 400 which was the going rate at that time. Forge on and make beautiful things Jim

-

Beginning Tools/Where to Start?

Jim Coke replied to Joshua Taylor's topic in Blacksmithing, General Discussion

Greetings Josh, There is what I feel the best school for blacksmithing in N.C. John C Campbell. Check it out on the web . Forge on and make beautiful things Jim -

Early 1900s or earlier forge

Jim Coke replied to Davishomesteadandforge's topic in Solid Fuel Forges

Greetings Davis, What you have is a Champion Wirlwind fire pot . The clinker beaker is an odd shaped ball arrangement with fingers that stick up through the slots. Not so easy to make.. I have a few but no pictures at this time. Forge on and make beautiful things Jim -

Greetings All . I’m sure that we all have a few cool pictures or signs in our shops. Some of my best. Forge on and make beautiful things Jim

-

Greetings Joy, The handle is a simple solution. A wheel barrow handle available at most hardware stores. The center grate is available on line for about 15 dollars or they are easy to make. Pictures of the forge would make it easier to determine the other parts that you need for your restoration. Several manufacturers made small rivet forges . Good luck and have fun. Forge on and make beautiful things Jim

-

Greetings Freddie, The best way to correct your problem is to remove the floor pads from your stand , level your anvil and stand than reweld the pads flush with floor.. Shims will only yield uneven surfaces . Good luck and have fun . Forge on and make beautiful things Jim

-

Das, LOL.... A few years ago I bought my wife a new Miata convertible . In the evenings I would suggest to her that we should take a ride through the neighborhood... Woops she finally put two and two together and realize that our rides was the same day as trash day. Whoops .. caught.. She now laughs at it. Forge on and make beautiful things Jim

-

Greetings Das, Congratulations to you both . Enjoy every minute for many years to come. Time flys as I well know our first daughter will be turning 54 in may and it’s still like it was yesterday . I have a picture of her in my tool chest when she just turned 3. Jim

-

Greetings Das, A simple (V) cut in the arms at the chisel pinch point would help with tension and alignment.. Just this ol boys 2c Forge in and make beautiful things Jim

-

Greetings Dave, Iam lucky I have 5 Hofi hammers only one of which is cast. ( pictured) It will be your go to hammer from now on.. Enjoy and have fun. Forge on and make beautiful things Jim

-

Greetings Brazer, Keep your stuff . Maybe a young sprout will come along that you can train and pass on your experience. As blacksmiths we have an unwritten obligation to pay it forward. Keep your body and mind moving you will feel much better. I have trained many newbys and will continue to do so as long as possible. Need a little help just ask there are many smiths in your area that I’m sure would come and give you a hand. Just this ol boys 2c . KEEP THE FAITH. Forge on and make beautiful things Jim

-

What did you do in the shop today?

Jim Coke replied to Mark Ling's topic in Blacksmithing, General Discussion

Greetings Das, Be carful building your demo trailer . I started simple and ended up with a solar powered unit with TV, sleeping area, hot and cold water, micro, sit down shower, portal potty etc, etc, I have used it for demos for the past three years and it works super. I started with a 6x12 plain trailer than went over the top crazy . I transport most of my gear in the trailer but some of the real dirty stuff ends up in the pick-up.. Have fun with your build I sure did. Forge on and make beautiful things Jim