-

Posts

2,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jim Coke

-

What did you do in the shop today?

Jim Coke replied to Mark Ling's topic in Blacksmithing, General Discussion

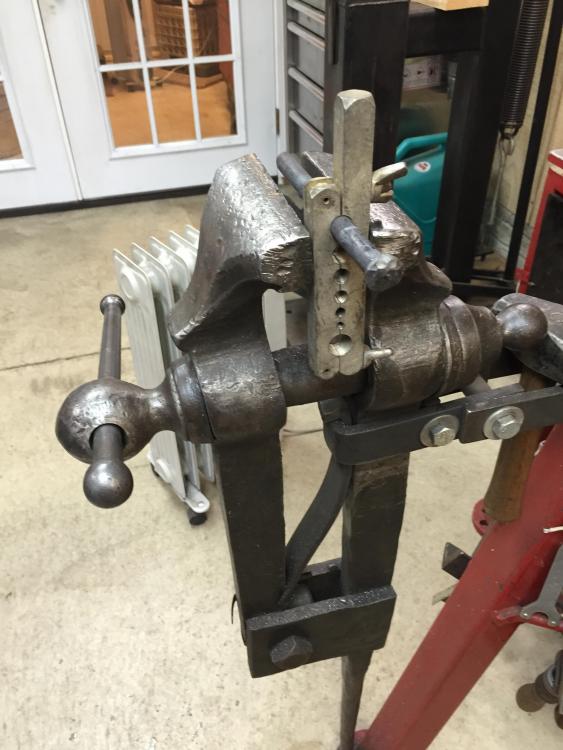

Greetings Stitch, Thought I would pass on my vice welding table. Simple 1/4 stock “T” with a circle cut out .. Makes it nice for multi position and butt welding . Make one up you will love it. Forge on and make beautiful things Jim -

Greetings Joel, IMHO. The metal twist is established on the first compression of the spring fuller. You might try a butcher to form the edge first. I ran across this using dies on my fly press. My solution was to use a cut off disc to form the edge instead of a butcher . In your case the cut should have about a 3/16 deep grove . Give it a try it might just work for you. Forge on and make beautiful things Jim

-

School project help- A blacksmithing project related to a country

Jim Coke replied to Mark Ling's topic in Everything Else

LBS. I do mine a little different at demos. I don’t sell them but if someone is interested I let them help and than I give it to them. Forge on and make beautiful things Jim -

Greetings 313, That all depends on how many bends,how close and if you are planning to do more-in the. Future. I have several set ups to diagonal bend . Some vise mounted and some much more elaborate. The quick easy way for just one bend is to place your stock in a v wedge swage on the anvil and with a wooden mallet to bend over the edge. No free lunch they all take practice. Forge on and make beautiful things Jim

-

School project help- A blacksmithing project related to a country

Jim Coke replied to Mark Ling's topic in Everything Else

Greetings LBS. How about a story board that shows the transition from the copper to bronze to iron. You could also include the transisition from bloom to wrought to carbon steel . You could choose the country of origin . Just a thought . You could finish your presentation with one of your fine pieces of iron work that relates to farm use. Your a great Smith with a fine mind I am sure you will choose something that wil yield .. AAA GOOD LUCK Forge on and make beautiful things Jim -

Greetings Rockstar, My advice is to pick a point and stay focused on it. You can’t give it your best or solve all the problems if your mind is on the big picture. When this works pass on your successful method to our government. Forge on and make beautiful things Jim

-

Greetings all, Lots of ways to skin a cat. My main Forge hood is an old recycled free standing fire place I got out of the junk, It has served me well for years. The pipe is 12 inches and goes straight through the roof.I can remove some fire bricks for big or long stock. Forge on and make beautiful things Jim

-

Greetings Das, Getting quite a pile there ( Resorce ) . We expect some new and different art to be posted shortly. Forge on and make beautiful things Jim

-

-

Making hardie tools

Jim Coke replied to bigb's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Greetings Mike. Yep it looks odd but it works great for holding large items on the anvil . I have lots of hold downs but this one is the go to for the big stuff , Just an adjustable pipe clamp modified for that purpose . The good part is the original clamp still works as a independent clamp. Forge on and make beautiful things Jim -

Making hardie tools

Jim Coke replied to bigb's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Greetings Jackdawg, I use a metal wedge to hold them in . It works super for many many applications. Try a few they are easy to make . Just a few more pictures that I have that shows the wedge. Forge on and make beautiful things Jim Greetings JLP, Yep I TIG weld but have been known to use any welder I can get my hands on easy . LOL Some have a little Bird Sh—- here and there. Jim -

Greetings Mike, I think you will find filling the box with sand is mistake . I have several potable set ups . The picture is one that is quite movable and uses your body weight instead of the sand. Poor picture but you get the idea. It works great and easy to move. Good luck on your build. Forge on and make beautiful things Jim

-

Making hardie tools

Jim Coke replied to bigb's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Greetings all, I have made tons of hardie tools. I personally like the ones I make that are subject to side thrust. I simply make a hoop that fits snuggly in the hardy hole than form up a simple wedge to hold them down . Try one you will love it. Forge on and make beautiful things Jim -

What did you do in the shop today?

Jim Coke replied to Mark Ling's topic in Blacksmithing, General Discussion

Greetings Das, I have a blacksmith friend in northern Michigan who named his son Iron . I’m thinkin FE26male.. Whatcha think ? Forge on and make beautiful things Jim -

What did you do in the shop today?

Jim Coke replied to Mark Ling's topic in Blacksmithing, General Discussion

Greetings Das, Congrats .. Daughters are fun and expensive but worth every penny . Got 3 and 3 granddaughters . You are indeed on a new adventure.. Cherish every moment. Jim -

Bending tube and bar.

Jim Coke replied to The Alchemist's topic in Blacksmithing, General Discussion

Greetings Alch, What size tubing? What wall thickness? What type of bend ? Drawings help Forge on and make beautiful things Jim -

Greetings All, I have several but these are my favorite 2. The gray one is a multi function unit that I designed . Forge on and make beautiful things Jim

-

Greetings Michale, That’s an easy one .. Just get a bucket mark it with the job title than put all the expired things in the bucket . Welding rods ,disc etc. Than all you have to do is figure in the expenses for welding gases , tool wear, than add in a fudge factor percentage. Forge on and make beautiful things Jim

-

Greetings Joel, I still think more than one coat of powder coating will give a quality look . I think it would be much stronger and retain its finish with a little flex factor.. My friend about 2 miles from me has a complete professional powder coat system so we can try some samples when you come up in the spring if you wish. Forge on and make beautiful things Jim

-

Greetings 1986, You can use the same procedure to make a button head rivet in the bolster just like a flat head . All you have to do is make a rivet header and upset the head round flush with the bolster. I make mine when I only need a few at a demo in the vise. The best is just buy some ready made they are cheap and readily accessible. Just my 2c Another suggestion, You can use a flairing tool holder ( lots available at junk stores) to hold a rivet when cutting it to size also works great for short pieces of round stock that are hard to hold in the vise.. Have fun. Forge on and make beautiful things Jim

-

Greetings Baja. Looks to me like a forming tool for a deep inside edge. I don’t think it is a struck tool. IMHO Forge on and make beautiful things Jim

-

Greetings Again, last time, In the winter months I mentor at the local trade school in the automotive department . High school students mostly farm folk, The subject of money comes up often and I am surprised at the answers I get when I ask them what money really is. I go on to explain to them that money is nothing more than a certificate of work hours. For example if you work at a job and make 10.00 per hour and when you take your girlfriend out to lunch at McDonald’s and spend 10.00 you have actually traded 1 hour of your life or time to eat. I go a little further and explain that the credit card is nothing more than a obligation of work time to be paid in the future.. Just for fun ask your kids what money is to them you will be surprised at the answers you get. Forge on and make beautiful things Jim

-

Greetings Joel, You might try several coats of powder paint to get the desired look. Depending on the. Element and it’s nooks and crannies it might just work for you. Just a thought. Forge on and make beautiful things Jim