-

Posts

583 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Upper Michigan

-

Interests

Medieval armour and metalwork, locks, clocks, history

Converted

-

Location

Leeds, UK

-

Interests

Medieval history, blacksmithing, armouring, silversmithing, sewing, and much much more

-

Occupation

Student

Recent Profile Visitors

7,376 profile views

-

I'll go through a lot of fuss and bother before I give up on my solid fuel forge I know I can do everything I normally do with gas, but I'm pretty happy with coal and charcoal. That would be my first choice, but it would mean the forge is in the middle of an already small space. I could play around with the layout, though, and see if I can get a comfortable working area like that.

-

Hi Frosty, There's a lilac bush behind, and that cherry tree on the left as well. I can't go through or near the gable because there's an enormous spruce on that side, so near the middle of the building keeps it the maximum distance from both. Ice and snow are an issue (they always are, right?) but I feel restricted by the trees and size of the space. I think a lot's going to come down to what the city says. Asking forgiveness isn't better than permission when forgiveness comes with a fine instead of three Hail Marys. And can you imagine what it's like hanging pictures in my house?

-

Has anyone ever made a super sucker hood without welding? I'll get a welder one of these days, but today isn't that day, and tomorrow isn't looking good either. It would be easy enough to put it together with screws, bolts, or rivets, but I'm wondering about air tightness.

-

A while ago I moved a town over, into a 120-year old house with a shed on the property. Last weekend my brother visited from Indiana and helped me haul much of the heavy stuff from my old shop to the new. I'm still cleaning out the shed, organizing, and there's a long way to go, but I'm hoping it'll be working by the end of summer. This does represent a major downgrade in shop size; the shed is 12' by 12', and my old space was more than twice that. I'd like to build a whole new shop, but that's not in the cards for now. Here's the shed. It is in fact leaning. So's the house. Across the road is the Caving Grounds, 100-year old iron mines that are, well, caving in. This area has been mined for iron since the mid-1840s, and there are still two big pit mines nearby. If anything on my property is square and level, it's by accident. I have to figure out the chimney, but it will either come out the roof or this wall, depending on what the code guy tells me. It's the one thing I'm worried about. View in the door. Obviously still a lot to clean out. I'm going to build a workbench along that back wall next to the shelves under the storage loft. Working out the work space. I have a stand for the blower but I may mount it to the forge to save a little space . The giant I-beam table has a hardy hole, clamp, and mount for a leg vise. The workbench will be the same height and I'll put them together. Then the red table will go by the door. I think I'll build a super sucker instead of an overhead. Not sure if it'll go off the side or towards the wall at this point. I'll post updates as progress is made!

-

Coal in northern Michigan?

Nick replied to Millhand's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Are you in Northern Michigan, or the upper part of Lower Michigan? Can't help you below da Bridge. There's no good source in the part of Michigan north of Northern Michigan. -

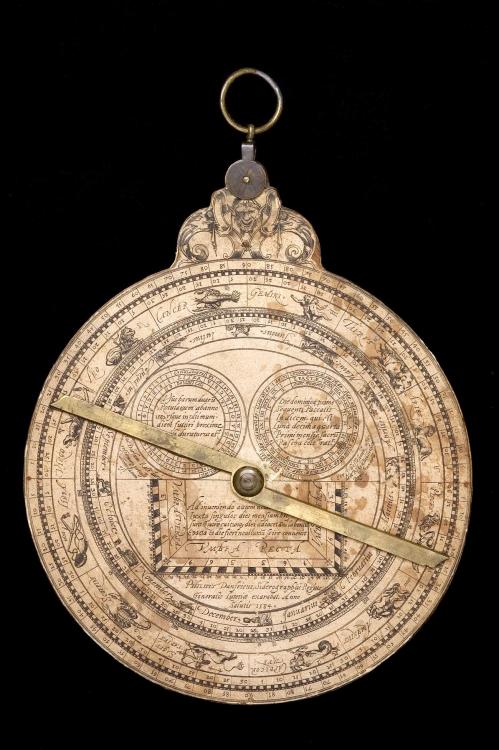

16th century wood and steel astrolabe

Nick replied to Nick's topic in Blacksmithing, General Discussion

Thanks, all! Frank, I didn't do the calligraphy, that was Danfrie, who was a printer as well as instrument-maker. Instead of individually made, engraved brass astrolabes, paper and wood ones could be made from a single block and were a lot cheaper (though sacrificing durability). There are a couple other astrolabes in museums that are made from the same printing blocks. -

The astrolabe was an instrument used by astronomers, astrologers, scientists, and others from the late 9th century until the 17th century or so. It consists of a stereographic projection of the dome of the night sky, over which is a projection of the major stars in the sky and the ecliptic (path of the sun in the sky). The back has a number of scales including calendars. Using the astrolabe, you can determine the local solar time based on the position of the sun or stars, the date based on the sky, the altitude of various stars and the sun, the height of buildings, direction, etc. According to the Islamic writer al-Sufi (d. 987) it had 1000 uses, and Geoffrey Chaucer wrote the English language's first tech manual on the astrolabe. They were frequently made from gilt brass and were status symbols as well as scientific instruments. Many, though, were made of wood and even parchment and paper. I've taught using the astrolabe in classes and fascinated by the things. I've made paper ones, but wanted something more substantial. This is a wooden astrolabe made by Phillip Danfrie in 1584. It's wood and pasteboard with printed paper and some copper alloy elements. The Museum of the History of Science in Oxford has excellent photos, including of it disassembled, which I was able to use to make my own. I used plywood, and heavy cardstock for the main body. The back is solid, and the front is a ring (to hold several climate plates, which are different depending on your latitude.) The "rete" (pronounced reet) was made from really heavy cardstock and I cut it out with a jeweler's saw. I made the metal parts from steel and brass brushed them. The central bolt was made from a carriage bolt that I filed down and rethreaded. The nut was made from another carriage bolt head. The sighting vanes on the alidade (the front rule), used to sight the elevation of the sun and stars, were tenoned and brazed. I drilled through everything and assembled. It's a little smaller in diameter than the original, but not much. The whole thing is sealed. Five climate plates for five different latitudes. The little tabs fit in a slot in the front to keep them oriented. I've used it and it's reasonably accurate. A good astrolabe is accurate +/- 2 minutes, but the rete is a little deformed on the original (and hence the repro), plus stellar precession. A very good astrolabe can be made for any latitude using a generator at astrolabeproject.com, which also has a good user manual if you want to learn how to use them. Sure, you can tell the time by your iphone, but isn't it cooler to be able to tell the time by the altitude of Deneb over the horizon?

-

When I make flat rings I make a template from a manila folder, then transfer that with a sharpie to a big, flat aluminum plate I have (metal is better than wood for this, doesn't scorch). As I work the bend into the flat stock I check it against the template, using the inside of the marker line. It goes quickly and when done I only have to do a very minor amount of correction around the weld.

-

Leaving the Country--Sell or store?

Nick replied to Ridgewayforge's topic in Building, Designing a Shop

For what it's worth, I lived in the UK for six years while getting my PhD. I just closed up my workshop, and when I moved back to the States it was there waiting for me. A little cleanup on some stuff, clearing out a couple mouse nests, and I was good to go. -

Oh that's nice! I've been thinking about taking the straight razor up again.

-

Some good friends from another state got married a couple years ago, part of their wedding gift were some local brewed beers and a Michigan wine and a custom bottle opener.

-

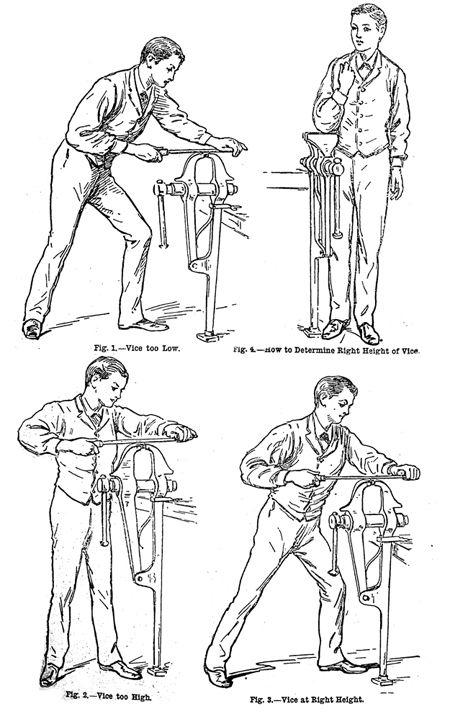

I found this illustration demonstrating how to determine vise height, similar to using the knuckles as a guide for anvil height. This is optimized for filing, of course. My vice is a little lower, which usually works well for me, but when I'm filing I do tend to lean against the heel of the anvil, which lowers me to about this height.

-

Thanks, guys

-

Looks like you'd need lefty and righty versions of that one.

-

They get shorter? I know the mark I want, a letter D copying one on the Avant armor in Glasgow, but for now I'll stick with a simple D.