-

Posts

19,293 -

Joined

-

Last visited

About JHCC

Profile Information

-

Gender

Male

-

Location

Oberlin, Ohio

Recent Profile Visitors

26,859 profile views

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

That's about $165 today.

-

In an IFI context, it makes more sense to add a comment to a thread you want to resurrect than it does to post a link to it. The former gets the original conversation going again, while the latter can create a separate discussion.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

The question isn't how we survived childhood; it's how many didn't. See Abraham Wald and the bullet hole map. -

I’ve made a couple of nice chisels from truck leaf spring after splitting it lengthwise with a handled hot cut and the treadle hammer.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

I believe powdered lime sulfur is the standard mercury spill cleanup, but I could be wrong. -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Also, cut away one side of my grinder station and welded in a frame made from an old bed rail: To hold a recently acquired tackle box: Which in turn holds supplies for the buffer: -

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

-

A few estate sale goodies; $10 total. The tackle box is especially fortuitous, as I have a storage need for which none of my other spare toolboxes were the right size.

-

When I was attending the college where I currently work, it was surrounded by cornfields. The same fields are still there, but nowadays they rotate between corn and soybeans.

-

Were the yellow jackets all holding the same chainsaw, or did they each have their own?

-

I'm one of those weird hybrids that use an iPhone and a PC, so I can't take advantage of the app's capacity for sharing between iOS devices. There is a cloud-based sharing option that I could use to edit phone uploads on my laptop, but I'm too cheap to spring for a subscription that I don't really need. Not at all! Just scan the books where they are, and it'll be easier to locate a particular volume within the chaos!

-

$4.99. There’s a field for “Physical location”, so you could number your boxes and add those numbers to each book’s record.

-

JHCC started following Book Cataloging App

-

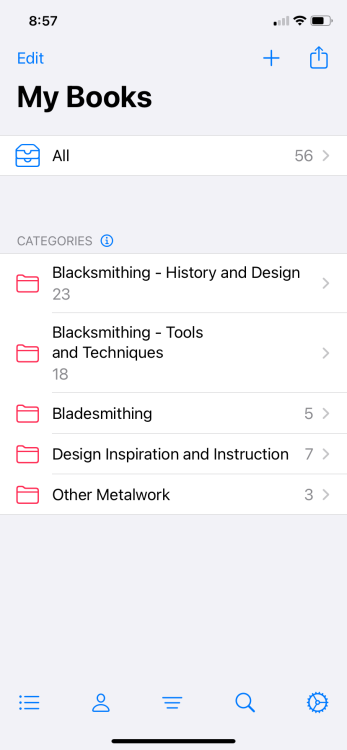

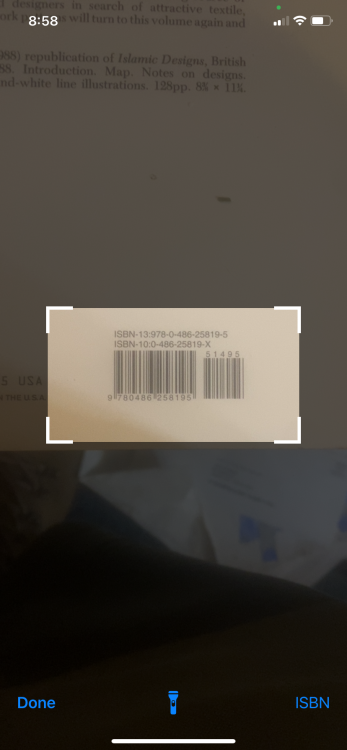

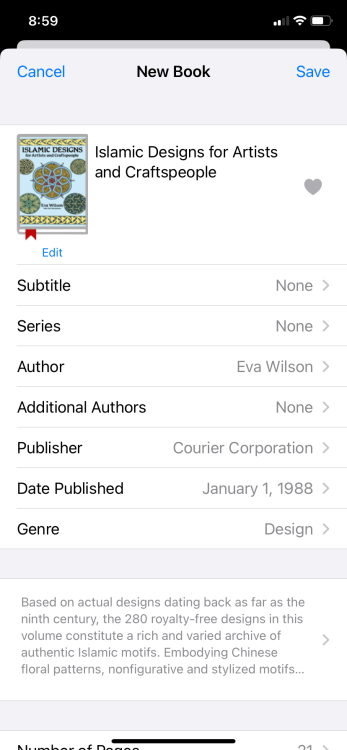

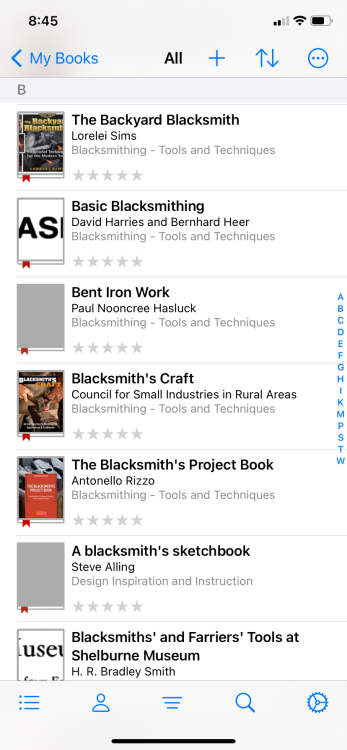

My smithing library has expanded beyond the point where I can remember all of the titles on my shelves. This is occasionally a problem if I’m browsing online or looking in a used book store, and a couple of times, I’ve ended up buying duplicates. In looking for a solution, I discovered a rather good cataloging app called Book Buddy, which comes in a free version and a paid version. These have the same features; the only difference is that the free version has room for a mere 50 volumes, while the paid version (a one-time fee, not a subscription) allows an unlimited number. The features I’ve used most so far are the categorization function, which lets you decide how to organize your books: And the barcode scanner, which lets you quickly identify books by ISBN: Without having to type in all their individual details: For books that don’t have a barcode, you can scan or type in the ISBN, and for older volumes that predate the ISBN system or that were published privately, you can enter the details manually. I haven’t yet tried it with periodicals (such as The Anvil’s Ting or The Hammer’s Blow), but I’ll keep you all posted on how that goes.

-

Is this slag?

JHCC replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

While you're at it, check out the Hopewell Furnace National Historical Site: https://www.nps.gov/hofu/index.htm. They've also got a pretty well kitted out blacksmith shop.