Hefty

Members-

Posts

282 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Hefty

-

I had heard of the Anvilfire site before but only looked at it in any depth recently when researching power hammer build designs. I only learned who Jock was and that he had passed away after that and still I can tell it was quite a loss to the blacksmithing community.

-

This thread is intended as a starting point for people wanting to know about what different kinds of naturally aspirated burners available to build or buy. When I first started looking around, it all seemed like too much information in too many different places and I wished I could find some kind of overview of the types of NA burners available. I’ve built a few of these burners myself now, but I’m still fairly new to it. I love to build things myself, either to save money (never really works out that way) or to learn more about things and better understand how and why they work. I’m starting to get my head around the how and why, but THIS IS NOT BURNERS 101. I’m not in any way experienced or qualified to give detailed information about HOW to build each of these burners. Different dimensions, and ratios of dimensions, and tuning methods apply differently to each of them and there are many members on the forum (Mikey, Frosty, AnotherFrankenBurner to name just a few) with far more experience and knowledge specific to their construction. (I know, because I’ve already asked the three I just listed many questions myself!!). Also, note that I haven't included information about NARBs as I'm mainly focused here on the NA aspect at the input end of the burner and I see ribbon, or multi-orifice, burners as being part of the flame side of the burner, similar to, or in replacement of, a flame retention nozzle. (And yes, I know that these all have very different tuning requirements and effects on the actual burner flame, too!) So, without further ado, here is a basic list of common types of NA burners and an entry level description of how they work: Frosty T burner: NA jet ejector burner where air is induced by gas from a mig tip drilled through the back of a 2 to 1 reducing T pipe fitting into the mixing tube. The two larger sides of the T allow maximum air to be induced and the “stem/upright” of the T is the connection to the mixing tube. Originally designed/discovered by Jerry Frost (Frosty) with detailed instructions in its own thread in the gas forges section of this forum. (I know this one - I've built two) Side-arm burner: NA jet ejector burner where air is induced by gas from a mig tip installed in a plug (or similar) through one side of a 2 to 1 T pipe fitting, with the mixing tube attached to the other side. Air is induced through the “stem/upright” of the Tee. The original version was a misinterpretation of Frosty’s instructions to make a Frosty T burner, by Robert Groman. A modified version was developed by Larry Zoeller using tapered reducing fittings. Z burner: A further development of the side arm burner, this is an NA jet ejector burner where air is induced by gas from a mig tip installed in a plug (or similar) through one side of a “Y” pipe fitting. I have no experience with these burners myself but my understanding from what I have read about them is that the air induced through the angled “stem” of the fitting tends to be more streamlined than from the side-arm and mixes better with the gas stream. Mikey burner: NA jet ejector burner where air is induced by gas from a mig tip through 3 (ideally - beveled edged) slots into the mixing tube. Designed by Mike Porter (Mikey) and presented with detailed instructions in his book. Linear burner: NA burner where air is induced by gas from a gas orifice, through a reducing funnel into the mixing tube with the direction of induction parallel/linear to the gas jet direction. There are many variations on this design. One well-known example is the design by Ron Reil. The original of the Ron Reil design used a hole drilled in a brass pipe mounted across the intake funnel. Other common variations replace this with an orifice in the end of a pipe centred on the same axis as the mixing tube. Vortex burner: NA burner, similar in concept to the linear burner, where air is induced by gas from a gas orifice (usually a mig tip or 3d printer nozzle) through a trumpet bell shaped funnel into the mixing tube. An "Aerospike" and vanes encourage vortex flow in the induced air as it enters the funnel, causing better mixing of the gas and air in the mixing tube. Currently well-represented by designs from AnotherFrankenBurner in the “3D printed plastic burner experiments” thread in the gas forges section in this forum. (I’ve made one of these so far but intend on making a few more) Fan-induced vortex burner: NA burner where air is induced by gas from a gas orifice, through a reducing funnel into the mixing tube with the direction of induction parallel/linear to the gas jet direction. A computer-style fan is used, not to force air, but to encourage vortex flow in the induced air as it moves through the funnel into the mixing tube. Designed by Mike Porter (Mikey) with pictures forthcoming when available. I'm sure there are more, and as I mentioned in the burners 101 thread where this idea started for me, some of this may need correction from those in the know, so please if you have more to add, post it below! Thanks, Jono.

-

Jet ejectors, that's right!! I knew it was "jet something" and I knew they induce air so I cobbled the wrong words together! You're right, I forgot about side arm burners, and I've heard of z burners but don't think I've seen one (or if I did, I didn't realise what it was). I'll do some more research and see if I can write up some more descriptions and add some photos (with credit where it's due) and maybe I'll start a new thread so it's easy for newbies like me to find. Cheers, Jono.

-

May I slightly hijack to ask a relevant burner question, please? I've searched the site (using site:iforgeiron.com) to find some threads and images to clarify, but I'm trying to find clear examples of each type of NA burner by their most common names. Can all of you people-in-the-know please tell me if I have all of these correct? (I've underlined where I'm not sure, or don't know) Frosty T burner: NA jet induction burner where air is induced by gas from (usually) a mig tip through a 2 to 1 reducing T pipe fitting into the mixing tube, originally designed/discovered by Frosty with detailed instructions in its own thread in the gas forges section of this forum. (I know this one - I've built two) Mikey burner: NA jet induction burner where air is induced by gas from (usually) a mig tip through 3 (ideally - beveled edged) slots into the mixing tube. Designed by Mikey and presented with detailed instructions in his book. Linear burner: NA jet induction burner where air is induced by gas from a gas orifice, through a reducing funnel into the mixing tube with the direction of induction parallel/linear to the gas jet direction. (Does a Ron Reil burner fit this description even though the original design has the gas delivered by a pipe at right angles to the orifice itself, or am I just splitting hairs?) Vortex burner: Is this the name used for AnotherFrankenburner's design that he has been experimenting with in the 3D printed burner design thread? NA jet induction burner, similar in concept to the linear burner, where air is induced by gas from a gas orifice (mig tip or 3d printer nozzle) through a trumpet bell shaped funnel into the mixing tube. An "Aerospike" and vanes encourage vortical ??? (is it "spin" or "flow" here) in the induced air as it enters the funnel, causing better mixing of the gas and air in the mixing tube. Fan-induced vortex burner: I haven't seen one of these but have seen Mikey reference the concept often in this thread. Mikey, have you (or anyone) made one of these, or is it currently a thought-experiment yet to be carried out? NA jet induction burner where air is induced by gas from a gas orifice, through a reducing funnel into the mixing tube with the direction of induction parallel/linear to the gas jet direction. A computer-style fan is used, not to force air, but to encourage vortical ??? (again, not sure if it's "spin" or "flow" here) in the induced air as it moves through the funnel into the mixing tube. What other types of NA burners have I forgotten? I haven't included NARBs because I was mainly focussing on the NA aspect of the burner, not the flame itself. With any necessary corrections, and maybe some pictures, I thought this might make a good starting point/reference for people learning about the different types of NA burners to find the info all in one place. Let me know how I did. Cheers, Jono.

-

I think it might be to raise the vise higher because the leg/post is too short for where it is mounted, compared to his working height?

-

"It's great therapy just to heat, beat and repeat." and "My forge is my fidget spinner" - Jason L (they'd both make good t-shirt slogans!)

-

Templehound, for such a BIG knife, it still has such good fit up and finish! Those fullers are a thing of beauty! Cheers, Jono.

-

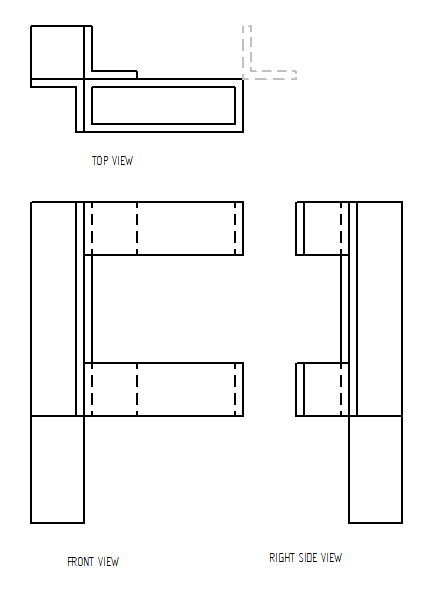

I saw and appreciated this video and it got me thinking about guillotine tools, too. I'm still only beginning my blacksmitherly journey and I'm planning to do bladesmithing and blacksmithing along the way, so I am planning an offset guillotine tool that will double as a blade fullering tool in future. Where Mark's has two pieces of square tube welded to some angle iron for the hardy hole, I'm going to make some form of hardy shank (tube/angle iron/etc) and then weld two opposing pieces of angle iron to it, upright, to make an "X" cross-section, then I'll weld two pieces of rectangular RHS into the opposite opening of the upright "X" to take dies made from some large leaf spring that I have. I'll have to either weld the top and bottom die guides on with separate pieces of angle iron "X", or cut the webs in between to allow the tool to be used from both sides. Depending on how sturdy I need it to be, I may weld another pieces of angle iron, offset to the outside of the tool, as another support on the far side. Here's a working drawing of what I'm thinking of. The possible offset support is in grey in the top view. Now that I look at it again, I might need to extend the offset on the right side view to allow a blade to fit past the hardy shank/upright. Whadya think?

-

Hehe, my mother said that time and again to my older brother and he had to suffer the same as her! I've also found myself, in multiple different contexts just this week, noticing how fitting Hanlon's razor (mentioned above) is.

-

3D printed plastic burner experiments (photo heavy)

Hefty replied to Another FrankenBurner's topic in Gas Forges

Jake, not sure if you have some knowledge and experience of CAD software but if you do, AFB's pictures of his different numbered versions will be enough to give you an initial design to tweak. That's what I did! Some things will depend on what software (if any) you have experience with. What I did was to insert one of AFB's images into a sketch, scale it to match the size of the pipe I had and trace it. Then I created a revolved 3d profile from that to get the "trumpet bell" funnel shape and the "aerospike" shape (as Frosty calls it). I then used the same method with one of his section views of the vanes onto the top view of the funnel and did a helical revolve to get the spiral shape (tools and terminologies may vary between software). I hope that makes sense. Cheers, Jono.- 863 replies

-

I just did a quick search and found a few. I won't list them all. Hopefully, others will be encouraged to look some up, too. I found it surprisingly interesting. Turns out the "duck test" is a razor. As in, "if it walks like a duck and quacks like a duck, it's probably a duck."

-

Coming up With a Touchmark Design

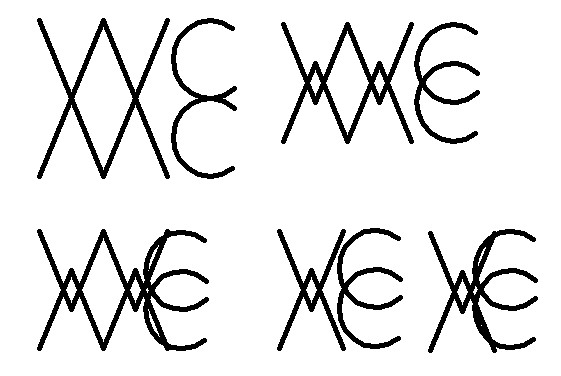

Hefty replied to NoGoodWithUsernames's topic in Tools, general discussion

I like it. Simple yet elegant. And there's plenty of room for tweaking the dimensions and proportions of the different letters, and the different "legs" of each letter. -

Not to hijack the thread, but would knee tongs like this work well for gripping pots/pans for campfire cooking? I've been thinking about making some as a replacement handle, kinda like a camp oven/dutch oven lifter but for a skillet, so I can nest pots and pans when travelling.

-

Judging by the shades of paint on the grass, it's freshly painted sheep fencing (Sorry, couldn't help but notice)

-

Mikey and Frosty, do you think notched "cut and shut" pipe methods could be used to make decent burners with tapered intakes and mixing tubes? I've seen youtube videos on this sort of method on a larger scale in the past (when I knew a lot less about burners) but I wondered if the inside would be too "chunky" to get good vortex mixing on smaller burners?

-

Nice!

-

Nice, thanks! Yeah, I just got a TIG welder myself and it's a STEEEEP learning curve!

-

What did you do in the shop today?

Hefty replied to Mark Ling's topic in Blacksmithing, General Discussion

Brings a whole new meaning to a "hot date"! -

Das, are your steel sculptures and ornaments MIG, TIG or stick welded? And, if TIG, autogenous or with filler rod? Cheers, Jono.

-

What's your latest blade look like? Post em and let us see.

Hefty replied to HondoWalker's topic in Knife Making

My first in quite a while and it's been a while in the making. Earlier this year my head of department gave me two springs from his 80 series Landcruiser so I started making this knife, from some of said steel, as a thank you for him. This coming week is our last week of the school year and I only just finished the final hand sanding! My brother made the sheath for me two weeks ago. My first integral bolster (well, sort of. It ended up quite slender), 4-inch blade, copper liners, Tasmanian Oak scales and a cyanoacrylate (super glue) finish. Thanks for looking! Cheers, Jono. -

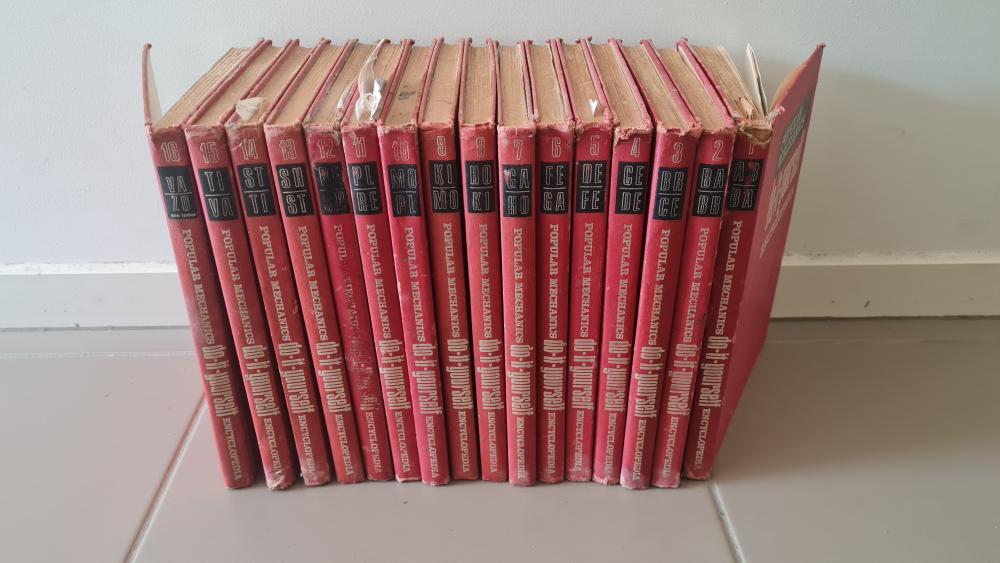

I've finally found something worth posting in this thread! I'm helping my folks pack up to move to an over 50's retirement village and they are trying to give me heaps of their old stuff. Some of it is great, some of it is not, but the best thing I've accepted from them so far is this: A full 16 volume, 1968 Popular Mechanic do-it-yourself Encyclopedia set! My late grandparents were American missionaries to New Guinea and my uncle (along with my mum and the other siblings) was born and raised in the highlands but with his upbringing supplemented by their connections back in the States so he got the full set shipped over! I quickly flicked through one volume and saw fully illustrated plans for a belt sander. Can't wait to see what else it holds!

-

Advice Needed For First Propane Forge Build..Cylindrical Or Square?

Hefty replied to MrMedieval's topic in Gas Forges

I can't remember exactly what it cost me to build them. I finished building my forge a few months back but I had made the burners about a year before that. I do know it was quite a bit cheaper than the Artisan Supplies burners though, because that's why I did it! Using 3/4" Frosty T burner as an example, a quick look at the bunnings website will get you a 20 x 150mm mixing tube for $4.62 and a 10 pack of 0.9mm mig tips for $5.67. They have equal tees for $4.04 so if you have access and skill with a metal lathe you could bore the intakes larger, or I think Frosty said it's possible to run an equal tee with a different mig tip size but not as efficient? Frosty, please correct me if I'm wrong! Otherwise, a plumbing specialist or steel supplier should be able to get you a 25x20 unequal tee and it'll cost you a little more. The flare fitting to mount the mig tip in is your most "exotic" item. You'll need to find a gas plumbing supplier that will sell to the public and not just tradies. I actually bought mine from Gameco and drove to their Brisbane warehouse on the northside to pick them up. If you're mounting the burners with the intakes lower than the hot end, you could order a 3/8 x 1/4 double male flare connector to go straight to a standard Aussie gas hose with a 3/8 flare fitting, otherwise you'll need some 1/4" copper pipe and make it a 1/4 x 1/4 double male connector. And if you don't have access to a tap set, you'll need to buy an M6 tap to mount the mig tip and I can't remember what size the big tap for the Flare fitting is, sorry! In the end, I think I spent about as much on taps and a pipe flaring kit as I did on parts for two burners, so if you've already got that sort of gear or a well-kitted friend who can help you out, the burner parts should be less than $60 for two, even with "exotic" mark ups for unequal tees and flare fittings. I hope that helps. Cheers, Jono. -

Advice Needed For First Propane Forge Build..Cylindrical Or Square?

Hefty replied to MrMedieval's topic in Gas Forges

MrMedieval, whereabouts in Australia are you? I'm in Brisbane and I found making 2 x T burners to be not so expensive but more frustrating to find the right parts for from places that didn't only want to deal with tradies. There were a few things I drove across town for to save on shipping, like some double male 1/4" flare connector fittings, and my local steel supplier ordered in 1" x 3/4 reducing tees for me because bunnings only had equal tees. It takes a bit of research and ringing around but you should be able to put some reliable burners together much more cheaply than buying 2 x Mr Volcano burners. Cheers, Jono. -

Coming up With a Touchmark Design

Hefty replied to NoGoodWithUsernames's topic in Tools, general discussion

If you named your business after the wild chickens, you could be Wild Chicken Metal Craft, with a square layout of vertically mirrored initials: I messed around with these options. I think I like the bottom row, centre. But, it's your smithy, your choice to name! Cheers, Jono. -

What did you do in the shop today?

Hefty replied to Mark Ling's topic in Blacksmithing, General Discussion

Happy spouse, happy house!