HondoWalker

Members-

Posts

104 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Albemarle, NC

-

Interests

wood turning, blacksmithing, geology

Recent Profile Visitors

-

What did you do in the shop today?

HondoWalker replied to Mark Ling's topic in Blacksmithing, General Discussion

Since I finally got a pretty good anvil and my step son finally moved his car I managed to forge a knife and a couple coat hooks. I've had trouble heat treating knives in the past because the forge isn't long enough to heat the whole knife at once. I had a good piece of wrought iron given to me by a nice member of this group. I used that to beat out a knife. I am out of practice and as a stroke survivor practice is critical to keeping up any learned skill. I'm not too ashamed of this latest blade. Much. I split a piece of 3/4 inch copper pipe to go between the steel and wood. I turned the copper down on top of the handle to hide the wood and make a fake guard. It's number 20 since I started forging. -

A collection of improvised anvils

HondoWalker replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

I've sat out for this year because my piece of junk soft steel "anvil" was working me more than I could handle. I'd gone down far enough to seriously consider cutting an old unused and mostly buried rail road rail. I hadn't done anything toward actually cutting an old rail beyond find some rails not used in over 50 years. I had asked around and gotten nowhere. I found out used steel costs $1 a pound at the local scrapyard so that was off the list forever. I had just about given up. Then my mother was driving by a group of rail road workers a couple weeks ago and she stopped and asked them about it. And they gave her 2 pieces!!!! One was for me. I've spent the last 2 weeks working on the new anvil. Glad I never tried to cut one. Had no idea they were that tough. Took me over a week to cut a small "horn". I gave up after so long. It's not perfect by any means and I've seen far better online, but I am a 7 stroke survivor so everything I do is much harder than it is for a normal person. Here's a picture. I've got it mounted where my old anvil was and it is much more solid and stable the other one was. -

What's your latest blade look like? Post em and let us see.

HondoWalker replied to HondoWalker's topic in Knife Making

I finished the latest one. Got it all shiny and sharp. Well I'm sick of messing with it so I can call it done. -

What's your latest blade look like? Post em and let us see.

HondoWalker replied to HondoWalker's topic in Knife Making

My latest knife so far. Didn't forge it this time. Got a few curved plow/rake thingys and noticed there's a straight part to it. So I cut it off and made a knife from it. The hole is from where it bolted on to the tractor. The wood is cedar guard is aluminum. -

What did you do in the shop today?

HondoWalker replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

HondoWalker replied to Mark Ling's topic in Blacksmithing, General Discussion

I got to try out my rebuilt forge today. Lit on the first try. Heated the steel just fine. But found it to be a little smaller than it was before. I made the pizza knife I had been wanting to make. I knew there would be no way I could get any holes drilled so I Punched a hole on each end. And again I had a heck of a time getting the punches out of the steel. Is there some kind of trick to poking holes in steel and getting the punch back out? I'm going to be in some serious pain tomorrow. My elbow is already throbbing and it's only been about 5 hours. Here's a picture just straight from the forge. It's going to be a couple weeks before it's usable on food. -

Good idea. I think I can make the modifications needed.

-

So the grate I made wasn't great. I had been using one that just had one hole a little over an inch wide. All those 1/4 inch holes add up to much more than just one inch. There's 25 of them. My logic had it working better. But then...7 strokes. Logic is no longer my forte. It's welded on and everything else is welded onto it.

-

So I rebuilt my forge using steel. I had no choice but to use the steel I had lying around. I had not read that you need thick steel. I reckon it won't last long. I have been trying to get to the local scrapyard for a year and a half now. Starting to think if I ever get to go I'll have to drive my lawnmower to it. They quit taking cans and are blaming it on covid. Yet I can't for the life of me figure why. Makes about as much sense as any of this covid nonsense they've been pushing. I'm beginning to think it's not worth fighting reality for any more. Been begging the wife to give me just $20 a month to spend and it's falling on deaf ears. I just don't have the funds to do any of this right. Physically it's torture using a hammer lately. I spent a week scraping up skid plates and the like for the forge and 2 days welding only to learn the only part thick enough to use is the grate. I'm not used to being defeated. I don't like it. And it's not helping my Christmas at all. I'd go back to turning bowls if only I could get the wood I need. It's getting to be too much for this stroke survivor. Who would have thought that only 7 strokes would beat me?

-

I attempted to do some forging yesterday. Spent the better part of 2 hours trying to get the fire going. Wasn't going to start so I gave up. Later I went to clean the forge up and it sorta fell apart. The cement and cinderblocks just couldn't take it any more and now they're gone. Would be a tragedy except this year I not only know how to weld but have a flux welder. I can now make it according to my initial design. My step son likes to leave car parts out by the forge so a couple skid plates have now been cut to shape. I even have a 1/4 inch thick plate I cut 2 inches of 1/4 inch holes into for a grate. Much softer than the piece of truck bumper I had been using. Therefore instead of a single 1 inch hole in the middle of my forge I'll have a decent grate that lets air through without allowing the pipe to fill up with cinders and coal. The vacuum cleaner I have been trying to use as a blower is dying quickly. My step son gave me a car jumper/power outlet/tire pump thing because it quit working. The battery is beyond charging. I took the thing apart and it has a nice little squirrel cage fan. Puts out the same amount of air as the vacuum used to. And since it's 12 volt DC I can simply add a rheostat and control the amount of air instead of the poorly working blocks I put in to keep from burning all my coal up in 10 minutes. Unfortunately tennis elbow has now affected both of my arms. So it's looking like it's time to find a way to construct a power hammer and a hydraulic press. Got a 12 pound short handle sledge hammer, a 5 hp tiller engine and some plywood. So something seems possible.

-

What did you do in the shop today?

HondoWalker replied to Mark Ling's topic in Blacksmithing, General Discussion

That's a great idea and I will look into it. -

What did you do in the shop today?

HondoWalker replied to Mark Ling's topic in Blacksmithing, General Discussion

Haven't ran the forge lately. Tennis elbow struck my left arm so that makes both arms that become useless with little effort. Been wanting to get me a propane forge going. I had an old air compressor tank that is 10 gallon. I cut the end off it thinking that was going to be my new forge and I saw how big it was. I'll never afford to run one that size. So I welded the end back on and turned it into a bbq grill. Yesterday I burned a bunch of scrap wood in it to burn off the paint. Today I eventually got hinges on it and got some tabs welded in so it holds the grill. At first I tried old cabinet hinges I had. They sorta worked until I had to manhandle it some and they broke off. I went to Lowe's and bought some good steel hinges and they were in in less than 20 minutes. Tomorrow I have to get the vent cover on it so I can adjust how much air it's getting. My wife says I need to put legs on it since it's so low to the ground. I don't have any steel that would work as legs though so it's gonna be short for a while. At least I don't have to worry about a cheap flimsy falling apart grill anymore. Now if only I had some charcoal and some meat. -

I use oak, cherry, cedar and maple for knife handles. I give them a soak in linseed oil after they're made and once it has sunk in I cover the handle with epoxy.

-

What's your latest blade look like? Post em and let us see.

HondoWalker replied to HondoWalker's topic in Knife Making

I saw a video of a guy who had a stencil for his knives and it seemed easy enough to do. I have no talent for drawing. But after a dozen tries I finally got a stencil that was usable. I tested it out on one of my practice knives and here's the result. -

What did you do in the shop today?

HondoWalker replied to Mark Ling's topic in Blacksmithing, General Discussion

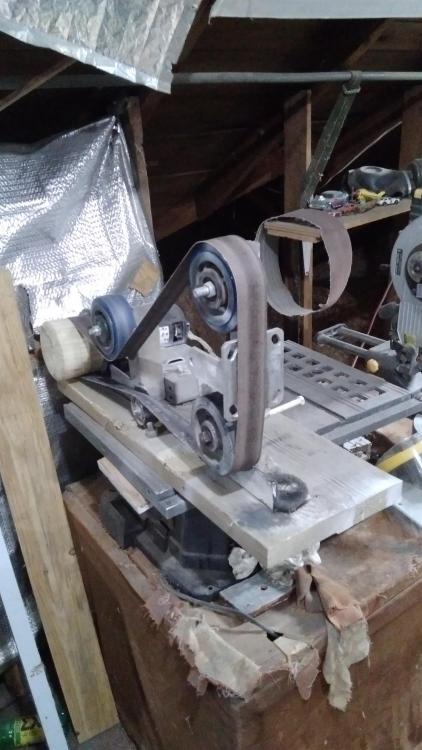

A home made type. When I first decided I needed one I looked them up and saw where they were way beyond any kind of reason price wise. So when I got my El cheapo flux welder I got some angle iron and a 2 inch wide wheel from my sister. When my stimulus came in I bought 2, 2 inch wheels from Harbor Freight. I found a piece of 2x12 and lathed me a drive wheel for the 2 hp treadmill motor I had. I'm amazed it works. It is litterally the first thing I ever made with a welder. It has eaten a few belts so far but it works good enough for me. And it didn't cost any $2,000 either.

.thumb.jpg.9802814310f3ad324a40356b3a41daf6.jpg)