BeaverNZ

Members-

Posts

351 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BeaverNZ

-

Hey Das Great work as always, The piece you have used as an abdomin looks like it is a cap to protect the tap on gas bottles though they usually have a female thread on the ones that I have seen mostly Cheers Beaver

-

If you are going to build a frame for your press make it as ridgid as you possibly can, a press frame that flexes can be thought of as a bow or catapult and will store the energy like a bow to throw any item out of the press with a great deal of force. Using members that are wider in the direction of the load or make it like a latice so you get more ridgity for your steel brought my workshop press is very ridgid and weighs about 3 1/2 tons but its very big and has a lot of power keep the width as narrow as you can as well its not that hard just do your research first Cheers Beaver

-

Another way of testing if the spark method doesnt work is to put a small tack of weld either arc or Mig and then get someone elses file and see if it files or not the carbon in CI makes the tack glass hard Cheers Beaver

-

Running the Massey 2CWT power hammer

BeaverNZ replied to BeaverNZ's topic in Power Hammers, Treadle Hammers, Olivers

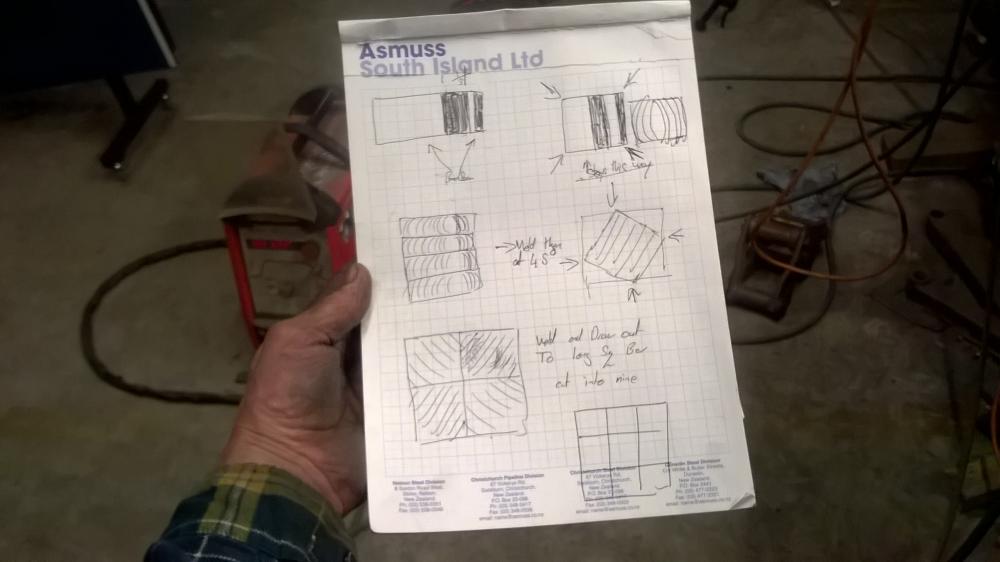

The stars have come out well so far just got to forge these together draw out into a bar cut into nine forge weld again then make it into something, Im thinking about a cleaver or maybe a large kitchen knife -

https://www.youtube.com/watch?v=wfeUB3DEUrQ I was using the hammer today to make a nine star pattern welded billet and so far I am having more joy than last week when welds kept on failing i think I had my billet too big for my furnace so far Im four steps into the process and should have a 1/4 of the first star. I am using crane rail track 1080 and large bandsaw blade L6? Inspired by Alex Steel I think pattern weled steel is very aesthetically pleasing

-

I shorted out a car starter lead on a car I was working on a long time ago with a metal watch strap, It went red hot in a nano second its amazing how long it takes to get a watch off when you want it off in a big hurry or it seemed that was the case. A spark down the top of your boot from off the end of the arc welder when welding overhead up a ladder is always fun as well

-

Nicely done

-

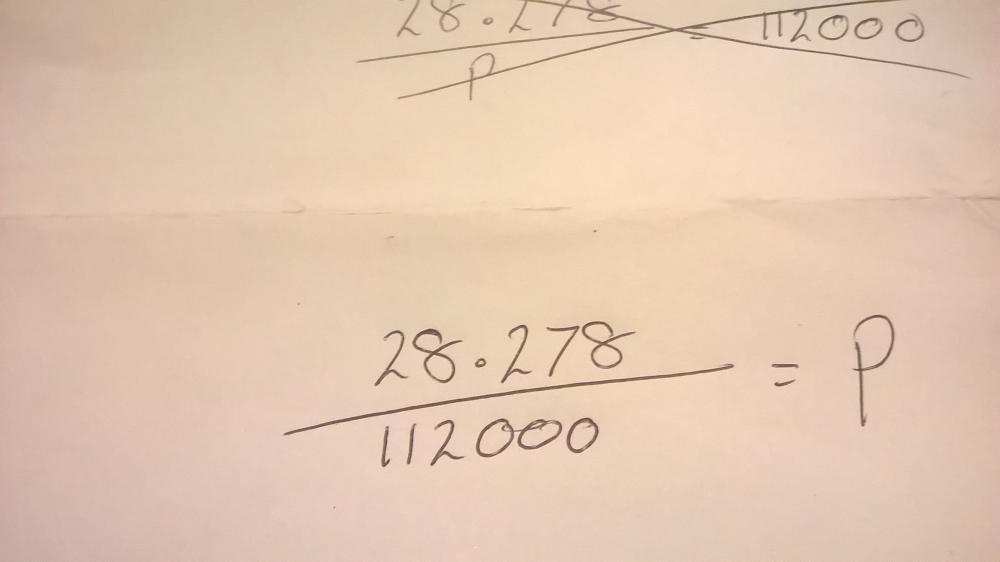

I stuffed up writing out the calculation, it should of been written like this but the answer was correct P was the answer all along

-

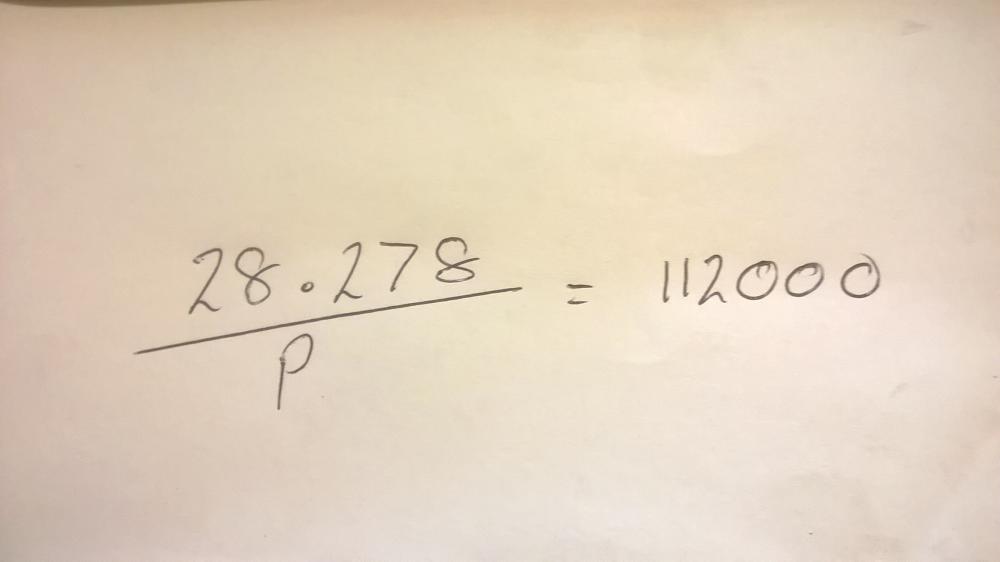

I have just done some calcs that would be typical to use on this site Say you are building a press and had a 6 inch dia ram and wanted 50 tonnes from it A 6 inch ram PI R sq 3x3x3.142 =28.278 sq inches piston area Convert tons to pounds is 50x2240=112000 lb so now to work out the pressure req we need to find P 112000 div by 28.278 = 3960.68psi

-

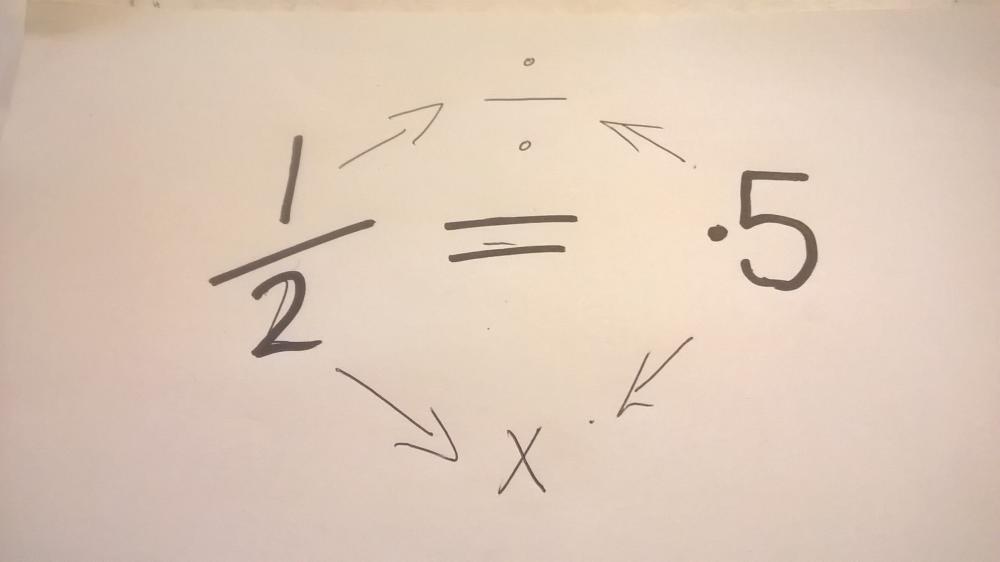

When I was at school I was the the oridginal dummy when it came to maths especailly when it came to stuff like algerba, But once I got to do trade related calcs gear ratios etc suddenly it all started to make sense as I had something to relate to eg a 50t sprocket driving a 200t sprocket 200div by 50 equals 4 but when a part of an equation is missing I could never remember what to multiply and what to divide and when doing my advanced trade certificate where there was some fairly heavy calcs to do I came up with the thing below and using something where you know all the parts 1/2=point5. One divided by point5 equals two and two multiplied by point5 equals one. So to find X in the next picture two multiplied by point 5 equals X or 1 Or to find A one divided by point 5 equals a or two All you have to do is plug in what ever numbers you are working with and you will get your answer Hope this makes sense it was a big help for Me and still is today Cheers Beaver

-

I think you will find metal is not porous, the water that appears on the surface is water condensing on the cold metal from the chemical reaction of the hyrogen in the fuel combining with oxygen and making water. This can also be a problem in the workshop if you have a unventilated fuel burner for heating LPG is quite bad for this as it has more hydrogen in its makeup than say diesel so makes more water when burnt. I have this happening in my workshop over winter and have found that a wipe with LPS2 works well on unpainted steel Cheers Beaver PS the surface getting a slight rust when heating may also be caused by carbolic acid from the CO2 combining with the water formed as well

- 8 replies

-

- plow disc

- harrow disc

-

(and 1 more)

Tagged with:

-

I reallise I may end up with a ventilated engine case if I get it wrong I have been doing alot of thinking about this one and I will use a EN36A or EN39B type of alloy the reason why is this what OEM conrods are made from and if you have ever wondered why single piece rods are copper plated is to mask where you dont want the rod to be carburised so it remains tough and not hard and brittle so just where it needs to be hard is where the needle rollers run. The hardeness reqiured is 60 rockwell. I have been experimenting with a sort of semi enclosed die made out of bissalloy 400 and the rod will req a bit of hand forging before hand. I cant use a roller bearing with an outer race though I had thought about it there isnt engough room and would add too much weight, yes I could get one made but I wish to do it myself if it was easy everone would be doing it Thanks for the replies and if you have any suggestions Im all ears Cheers Beaver

-

The duct tape will double the speed and power of the motor Lol

-

Instead of focusing on a press have you thought about using/making a roller type press for drawing out your bar stock there is lots of good examples on good old youtube and they shouldnt be expensive to build with a bit of cunning scrounging Cheers Beaver

-

Hey guys has any one had a go at forging single piece conrods for an engine I am buliding a dirt bike with a heavily modified engine and I am set on having a go at making my own. I know I could by one or have a machine shop make but thats not me. I intend to use a high tensile case hardening steel so I can get the needle roller positions hardened by carburising I have a rough idea of how to start but thought I would see if any one else has been down this track Cheers Beaver

-

hydraulic motor driven little giant Hammer

BeaverNZ replied to Krush's topic in Power Hammers, Treadle Hammers, Olivers

Actually I was thinking about this and the low presure another way of doing this with your pump is use a smaller displacement motor that will require a higher presure to run so it uses the pump in its lower output/higher presure but im not sure how efficent this setup would be have you already got the pump, I could ask the local hydrulic company for advice that I deal with what horse power electric motor have you got or do you have a good grunty electric supply do you have to have a dual stage pump?. Another thought has just ocurred if you use the hyd motor you can do away way with the clutch and use a spool valve or flow control and direct couple to the drive. -

hydraulic motor driven little giant Hammer

BeaverNZ replied to Krush's topic in Power Hammers, Treadle Hammers, Olivers

I would think it should work as long as you keep below the kick down pressure, Some of the cheaper pumps have trouble with wearing out the seat of the kick down valve after a bit of use so be mindful of that as far as working out the speed goes find a conversion chart to convert gpm into cu/in per min then divide by 6 and that will give rpm. It would probably more energy efficent to use another motor dedicated to the hammer but i can under stand trying to maximise your equipment Also be mindful of hose sizes and use large radius fittings if there are any angled fitiings any restrictions is lost power and heat generated and 500 psi is a very low pressure to start with Cheers Beaver -

Its a sad day when you dont learn anything I have been in engineering for a living since 1992 and when I was younger used to spend all my time in my fathers workshop and had nothing more advanced than a hand hacksaw blunt files and damp old electrodes ( It was a farmers workshop ) It used to take me days to do the most basic things. One of the main reasons I enjoy IFI is there are so many people who know alot more than me and are willing to share their time and Knowledge Cheers Beaver

-

Hi I just had a look in my stainless book to make sure I had it correct but the 300 series of stainless steel wont harden by heat treatment though can be hardened by cold working Austenitic Stainless is non magnetic Cheers Beaver

-

Need help identifying this coil spring

BeaverNZ replied to cedarghost's topic in Blacksmithing, General Discussion

I have access to track springs from diggers as they break some times especailly they forestry harvesting diggers as they take them in such crazy steep ground they wear a 5 point harness just to stay in the seat!. I have just yesterday forged one of these in the power hammer to make some tooling out of it ended up being 40x40mm square. The strongest track spring I have had apart in the press was a 45 tonne spring. Its going to be interesting to see what properties they have -

Thomas I would guess it is hot rolled and them heat treated its probably some secret squirel industrial process. Thinking about it the rolling process would make any grain move along the long direction of the plate. Cheers Beaver PS I can remember watching that vid thousands of years ago when doing my apprenticship Maybe it depends on to what extent it is heat treated ie what temp its taken to after rolling?

- 32 replies

-

- heat treating

- forging carbon steel

-

(and 1 more)

Tagged with:

-

Just My two cents worth, When bending a high strength steel like bissalloy in a press brake the full size sheet when delivered from the steel mill/supplier has a grain direction marked on the sheet and when bending it you should bend across the grain so there must be something in the grain argument Cheers Beaver

- 32 replies

-

- heat treating

- forging carbon steel

-

(and 1 more)

Tagged with:

-

My new to me LG 50lb. Hammer

BeaverNZ replied to Reeg's topic in Power Hammers, Treadle Hammers, Olivers

If its off center it may to help counter ballance the crank so it stops with tupp up. Is that a Ford or Chev pannel van/delivery lurking in the background? Im into hotrods too Cheers Beaver On second look its probably a thrust block to take any load from the clutch but Im just guessing- 5 replies

-

- little giant

- power hammer

-

(and 1 more)

Tagged with:

-

What is the most dangerous tool in your shop?

BeaverNZ replied to Glenn's topic in Tools, general discussion

Frosty I like the tearoff idea Next timeIm at the bike shop I will have a look at them I have always used a rolloff google system on the bike Cheers Beaver