setlab

Members-

Posts

199 -

Joined

-

Last visited

Profile Information

-

Location

Florida

Converted

-

Location

ohio

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Quad state September 22-24, 2023

setlab replied to BillyBones's topic in Events, Hammer ins, Where to meet

Been there many times, not in the last few yeas though. I've noticed a trend every year I go, it gets a little smaller and smaller every year, barely any old power hammers being sold anymore. Would I pay $40 to walk around the flea market and look at the art display, maybe, lots of not common stuff to look at. Astronomical prices mean I might buy a few pieces of junk for $30 after a $70 entrance fee and watch maybe 30 minutes of demos. So at the end of the day I end up with $100 of possibly useful junk that's only worth $20 lol. -

Quad state September 22-24, 2023

setlab replied to BillyBones's topic in Events, Hammer ins, Where to meet

$70 just to walk around Saturday? Yikes, no thanks. When did quad state get so expensive? -

Thoughts on small air hammers? (Anyang 15kg/33lb)

setlab replied to Vinito's topic in Power Hammers, Treadle Hammers, Olivers

I hear ya, don't shoot the messenger haha. It's just pretty surprising to hear a low end of 2k. Maybe 2k is for one that's been threw a couple floods and outside rainstorms. Now that it's on my mind I'll have to take a look at my hammer and see how attached I am to it still. It has a pretty big cool factor even though I never use it lol. -

Thoughts on small air hammers? (Anyang 15kg/33lb)

setlab replied to Vinito's topic in Power Hammers, Treadle Hammers, Olivers

That's a little surprisingly low I would think but who knows. Maybe I'm bias but a well built tire hammer doesn't sell for less than $3500 often. A self contained hammer > a tire hammer any day in my book. -

Thoughts on small air hammers? (Anyang 15kg/33lb)

setlab replied to Vinito's topic in Power Hammers, Treadle Hammers, Olivers

What do you guys thing a good asking price would be for an old style anyang 33lb hammer with the markets the way they are now? Have one in storage but being honest with myself it will probably be years before I even think about using it. -

Tire hammer build questions

setlab replied to IronChef's topic in Power Hammers, Treadle Hammers, Olivers

The 1" bolt is just used as a shaft, the threaded portion gets cut off. I assume Clay picked that grade of 1" bolt to allow for more shear force on the shaft, which is important if you want to put a lot of time in forging with the hammer. Also using a bolt makes it easier to weld it perfectly perpendicular to the flywheel by threading a nut and washers on before hand. For the anvil, probably the most readily available to anyone material would be 1/2" plate. Cut to size and stack it up to weld. -

Surprisingly no, the repair manual doesn't say what type of oil is best. The only mention of oil is more of a sales pitch "...reduced wear and noise due to cavitation. Thus allowing heavier viscosity fluids to be used". You bring up some interesting points I'll have to read up on. I'll give a local shop a call tomorrow and see if they can recommend me a type to use.

-

I bought a big hydraulic powerpack/press a while back and the fluid is getting kinda nasty and old in it. What do you guys use in your hydraulic presses? Does the weight of the fluid make any difference? My power pack was made sometime in the 70s and the manufacturer has long been out of business. I do know it's a single stage pump that will be producing about 30gpm from an old pump repair manual though.

-

You can use that to cut RR track, If you have a long piece just mill the slides travel at a time and re-clamp. As far as what to use, just use an older mill bit you already have, or a face mill, or a fly cutter, or anything that fits in your collets. Buy the cutter that you get the best deal on, 2"-3" seem like a useful general purpose size to look for though. Keep an eye out for Facebook/craigslist/auction bulk lots of endmills for some really good deals. You'll probably find 1/2", 3/8", and 1/4" are really useful sizes in just about anything. That mill is a game changer for sure, wait untill you put a cheap digital readout on it though!

-

I didn't read anything above me yet, I assume bomb has been mentioned by everyone, that's worst case scenario based on your honest assessment of your welding abilities and fab equipment. It's a real life don't cheat yourself scenario. That said, you're going to waste a lot of time and money hodge podgeing random log splitters together. You've probably made your mind up if you're going to do it already, but I'd advise you to start off with baby steps. Just buy a harbor freight air/hydraulic jack and use that in a frame, they can be very capable in that role. Or just use one log splitter, don't think a rube goldberg contraption of a bunch of log splitters is going to be any better than just one when you are forcing yourself to be a cheap skate on parts. That said, deals are out there for hydraulic presses if you go the air/hydraulic cheap route and wait until a real press comes along. I bought a 60 ton extremely fast industrial press for $400 as example just searching Facebook marketplace. I've seen 3 small presses, and multiple power packs in the last 6 months at auction, so keep an eye out for industrial auctions and scrap yards you can buy from.

-

Oh wow, ya 3d printing has come a long way in the last handful of years. There's actually a few really big databases of free print files too. Odds are if you think you want to design something someone already has and posted it online. Link removed per TOS is a pretty good one. For a slicer I use cura, its free and is pretty easy to use. As far a printing goes, it's as simple as downloading your xxxx file, opening it in cura, clicking slice, then moving that file to your printer with a thumb drive.

-

Frosty Have you looked at the ender 3? I have a cr-10 which is essentially the same but a little bigger and am pretty impressed with it, found it as an Amazon warehouse deal at a pretty nice price. I've seen ender 3s occasionally on sale for around $150 and they can print lost wax. Actually you can print normal PLA plastic and melt it out of your molds prior to pour. On YouTube there a channel, I think it's called myfordboy, he has a few really good aluminum casting videos using the 3d printed lost PLA method.

-

That's just a homemade widget holder. Like someone above said, probably an indicator holder to tram a mil. Don't get your hopes up it might be worth a few dollars to someone, however if you need to tram in a mill you can make your on indicator holder really fast. So what you got there is a fancy piece of scrap if you don't have a mill honestly.

-

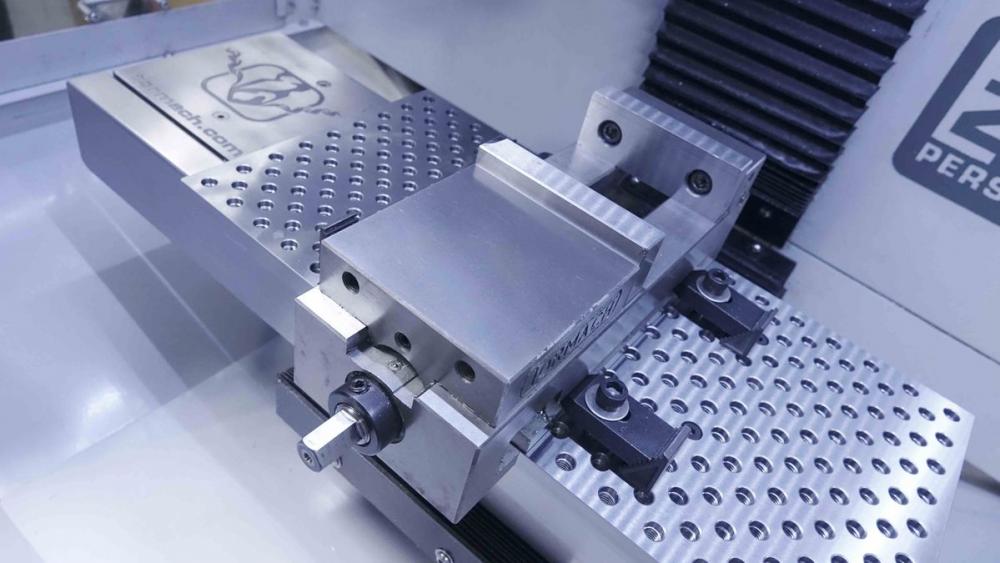

It's going to be really interesting to see what my speeds and feeds can be on steel with this little guy. I'll probably never make big widget things for the sole purpose of resale, this is mainly a way to teach myself CNC with my limited space at the moment. I could see myself doing small batches of parts though, like that scope wheel, as a production project. A big motivator to paying way to much money for this mill was to boost my resume, this kind of stuff lines up pretty well with the industry I'm trying to get my foot in the door at. Steam punk guns would be pretty cool! Along those similar lines I've had a vision to build a beat up looking post apocoliptic AR or AK with some random repurposed things. Like making a beat to hell rough forging of an AK receiver and then milling it out keeping the outside raw look to it. Or just pulling random parts from my scrap yard that kind of have the same outside dimensions and machining the insides to spec. Even though I have a bunch of cheapo Anderson lowers I just can't bring myself to messing one up in trying to junkify the outside of it lol. I've been looking at Saunders machine fixture plates as of late. Having extremely accurate dowel pin locators for quick vice and fixture swaps and having an overhang from the milling machines bed is defiantly the way to go. I think I'm going to draw one up and take it to a local machine shop to see if they can compete in price. With a piece of hardened 4140, I almost think the only way to accurately make a parallel fixture plate would be to hardened the material, send it to the surface grinder, then drill/tap/ream holes in the hardened ground material? I'm not extremely knowlegble about the processes industrial heat treatment facilities use, but I'm fairly certain that if the machining process above was done in reverse to bring down tool costs the heat treat process would most likely cause very minute changes to hole dimensions and flatness.

-

I just bought a tiny CNC mill DM2800 at auction that's pretty similar to the Tormach 440 in build quality and capacity (8x6x7 tool path). I'll probably have some retrofit work to do to this 1990's mill, I'm most likely going to put an Acorn control system in it. Anyways in the mean time to kill some time, what would you guys make with a tiny CNC mill? My immediate thoughts are to work my CNC fixturing skills up enough to where I can cut bevels into folding knifes and mess around with those for a while. I know it's kind of unrelated to this forum, but I think I would get a lot of use building robotics projects too. In addition to 3D printing, I think this little CNC mill can really be a game changer to make conceptual designs reality. I don't have any good pictures of my mill as of yet but here's the model I'll be working with: DM2800 axis capabilities