BeaverNZ

Members-

Posts

351 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BeaverNZ

-

Motor question- VFD or single phase

BeaverNZ replied to Dan P.'s topic in Power Hammers, Treadle Hammers, Olivers

If you are limited in the size of motor by starting current as starting under load the current draw can be five or more times running draw, you could fit a backing roller or snub roller to over length drive belts to work as a clutch so you can start the motor under little load and then slowly engage the belt tension to get flywheel up to speed. 940 rpm means its a 6 or probably 8 pole motor which means it will be expensive to get another the same rpm Cheers Beaver -

Annealed file remained hard...why?

BeaverNZ replied to arkie's topic in Heat Treating, general discussion

Steve ,Im just an old plodder and possibly a bit obtuse LOL I have read your article on annealing which was interesting but wasnt it dealing with alloy steels when the subcriticle methods were used and the file steel in question just a plain carbon steel? I am interested to learn more thats why I spend more time here than I should at times Cheers Beaver -

Annealed file remained hard...why?

BeaverNZ replied to arkie's topic in Heat Treating, general discussion

yes Steve I have read the whole story Im just thinking out loud, maybe he has very poor temp control? just putting out ideas why this is happening. Isnt all tempering regardless of the amount done at subcriticle temps? I was just rereading some of the other resent posts. I may be interesting to here back from Biggundoctor . -

Annealed file remained hard...why?

BeaverNZ replied to arkie's topic in Heat Treating, general discussion

I may stand corrected here but even just tempering should remove enough hardeness to allow an item to be drilled or filed if taken to a black/blue colour unless its a high speed steel alloy -

Power hammer forging rivets,

BeaverNZ replied to BeaverNZ's topic in Power Hammers, Treadle Hammers, Olivers

Dave thats just it, you cant get rivets here unless you import them from England or you make them yourself so i did as I like making tooling and in the long term should pay for its self Cheers Beaver -

2.24 lb is 1 Kg 1 Kg is 1000 grams 2240 lb is 1000 kg

-

Annealed file remained hard...why?

BeaverNZ replied to arkie's topic in Heat Treating, general discussion

For drilling a problem steel you often have to run the drill at 150/200 rpm or slower if you have the chance thats when using a small drill 3mm or about 3/16 and i have found that a GOOD quality Ti coated drill is a good investment though once sharpened the coating is void. I have found that there are alot of gold coloured drills claiming to be Ti coated but just dont cut it. If you run a drill too slow it just takes longer to drill but too fast and it just stops -

Annealed file remained hard...why?

BeaverNZ replied to arkie's topic in Heat Treating, general discussion

I think its probably unlikely to have a hard part part way through, it maybe the workpiece work hardening from the drill going blunt by it being driven too fast or the drill having too much back clearance or rake this makes the cutting edge weaker as its not as well supported (I often reduce the clearance on new drills ). When drilling a high carbon or alloy steel reduce the speed to about half the recomended speed for mild steel or more is required sometimes for alloy steels and use a heavy cutting pressure to make the drill cut and not rub, this is important with stainless steels as they are really prone to work hardening. My big old drill pres goes right down to 28 rpm and thats too fast some times when driling with larger drills in wear resistant plate Cheers Beaver Ps good old kerosene makes a good lube for hard steel or Rocol RTD -

The press frames of dubious parentage are designed close to their point of failure and have alot of flex because of this just bear in mind that your press frame is not unlike a bow as in bow and arrow and the more flex the more stored energy to throw any item if you have something get thrown of break under your press. I recomend that you make your press frame as ridgid as you can, go around a steel fab shop that does structural steel work and offer to make a donation to their social fund or bring beer/donuts/dancing girls or any other enticments and its amassing what can happen as offcuts just get binned usually Cheers Beaver

-

Its very low tech and needs to have a better way of holding the two sockets so they are easier to change but this keeps the twist even and inline with the center line of the work piece Chers Beaver

-

WOW thats fantastic work Beutifull work

-

-

Power hammer forging rivets,

BeaverNZ replied to BeaverNZ's topic in Power Hammers, Treadle Hammers, Olivers

JHCC thanks for that I dont know why it wouldnt for me I even tried lots of swearing while doing it and it didnt help either Cheers Beaver PS I dont beleive my fingers are in any danger as they are not under where they can be crushed but a handle is on the list as the dies do get hot -

Power hammer forging rivets,

BeaverNZ replied to BeaverNZ's topic in Power Hammers, Treadle Hammers, Olivers

I have tried that many times and it just wont work, I am wondering if you tubes settings have changed as I cant post to my business FB either -

Power hammer forging rivets,

BeaverNZ replied to BeaverNZ's topic in Power Hammers, Treadle Hammers, Olivers

If you want to see tooling being used have a look on you tube under title of Massey power hammer forging 1/2" rivets and you should find it -

-

The tonnage produced is dirrectly related to the pressure put into the ram, For the pressure to accumulate there has to be a resistance to the rams movement. What the above statement MAY be refering to is if the ram is used unsuported in like a press then to prevent kickout of the ram shaft getting bent the pressure needs to be reduced but Im only guessing there, I susspect that that statment is for a ram constructed to have a 16 inch stroke total. As long as the ram pivot or mounting points are in line with the centre line of the ram and free to move a ram with a 28 inch stroke should be ableto be used to its full design pressure for the full stroke. All this info should be freely available online if you look

-

Stroke length has nothing to do with the tonnage produced

-

When a hyd rams design pressure is exceeded with a well sourced component, modern design ram usually the worst that happens is the internal piston seal is extruded past the piston and this can happen on just one side which loads the piston against the cylinder wall and causes scoring. Its best to have excess stroke and not use the full stroke extenstion as this helps support the ram shaft from getting kicked out and bent Cheers Beaver

-

Hi Mark1 Being rich or wealthy in a money sense for Me wouldnt be the end of the world, it would be a burden I would just have to bear LOL What my frustration is about is the supprestion of the hourly wage of people who work with their hands for a living and now there is a skill shortage starting here from a lack of apperentices and training over the last 30 years. so hopfully the wages will start to increase in the future again for skilled people but our beloved polititions have been talking about allowing more people in from overseas to fill the gaps which is Ok to a point but as long as everybody gets a fair go at a decent rate

-

This is per hour I forgot to put, I was having a conversation with the manager of one of the largest engineering businesses in Invercagill and we got onto the subject of margins on materails, I mentioned my 40% and he said really I am happy with 10% admitally he is often dealing in 100000 of dollars and much more but does that mean that because it a larger sum of money you are not allowed to make as much profit on your money invested?. I told him i wouldnt even bother for 10% and yet people are perfectly happy to buy clothing or stuff they dont really need and the margin is 300%. Or go to your so called profestional (Laywer, Dentist etc or any other of the expensive parsites) and they just except it. I sometimes barter but you have to be carfull here as you are trading with things that may have differing values for the parties involved so you need to know exactly what each party expects and be sure both will deliver

-

For Me this is a constant source of frustration I charge $60 plus GST at 15% (goods and services tax) there are other names for this but it would get me banned, plus consumables, vehicle charged out at $1.20 per Km, Mig welder $1.00/min Oxy/acet $1.00/min unless its a large heating tip them its more, Stick welding rods $1.00 each some of the special rods are up to $7.50 each. When I purchase any items steel or any other items I add 40% markup All of these are plus GST. As I get older I have become a lot less tolerant of people wanting stuff done right now but do not want to pay much for it I am very blunt and to the point Cheers Beaver

-

These are two of my first claw hammers these are practice for when I get cosistant enough to make them out of pattern welded steel the first pic is upside down stupid smart phone but the unfinished hammer thats as far as I am going with that one as I used a hot cut to isolate for the claw and I should of used a radiused tool instead as it has formed a bad lamination

-

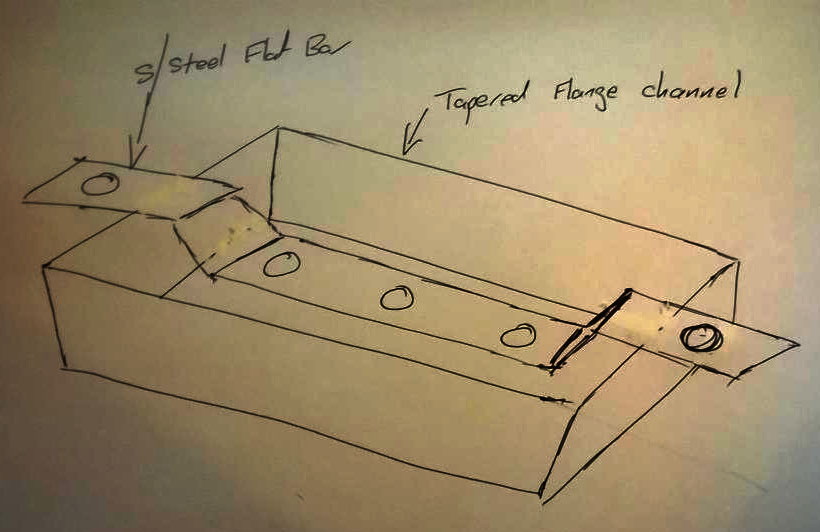

While I wont go into how you heat the zinc this is how I would cast it after making sure the mould was properly heated before pouring in the metal. There is probably already stainless steel bolts welded where an anode has been in the past and this stops damaging the paint and antifouling of your hull if not you should fit some. Just be mindfull that too many anodes can be as bad as none as you have to have a ballance because you are basicly making a battery. The holes in the stainless strap in the centre are to increase the keying of the zinc and stop it coming loose and the strap just rests on top of the channel and the zinc will be held slightly off the surface of the hull Cheers Beaver

-

If budget is a proplem have you looked at a rolling mill they could be made for a small amount with some talented scrounging and from what I have seen of them they work very well