-

Posts

3,535 -

Joined

-

Last visited

Contact Methods

Profile Information

-

Gender

Male

-

Location

Atherton Tableland (Promised land) Far North Queensland, Australia

-

Interests

Metal work: blacksmithing, junk sculpture. Timber work: turning, furniture. Photography, aviation, motor sport. English teaching.

Recent Profile Visitors

12,538 profile views

-

Thank you all for sharing your experiences and writing comments here. I will be starting the forge again on Sunday after about 6 weeks away from doing the daily demos. I'll start with three days a week plus Sunday and just do an hour or so each day. Don't want to overdo it, and I'll stick to small S twist hooks, troll crosses and such for the moment. Tourists really don't care what you do so long as they see hot steel being moved. And I shall be sure to have that bottle of water near the forge at all times. I learnt my lesson! Cheers everyone.

-

Thank you, sir.

-

I'm not sure if this is the appropriate place for this post, but just felt that I would like to make this comment in the interests of personal safety and general health. Admin please delete if this infringes the guidelines. I may be preaching to the converted here, but I think people who work in an environment such as ours, especially in hot weather need to be acutely aware of the need for good hydration. If you are working over a hot forge in hot weather and you have not had a drink all day, you are not doing your body any favours. I have been away from this forum for quite some time due to poor health, and it's not until recently that it was brought home to me how I have been neglecting my body for years simply because of lack of water. Even if you don't feel thirsty, it is important to keep your fluid levels up. If you don't look after yourself in this way, especially as you grow older, it will catch up with you in the end. Like many us, (well, blokes anyway), we may suffer from enlarged prostate as we grow older and that condition can impact severely on your ability to expel fluids. I required a very fast trip to ER because of urinary retention which is a very serious, frightening and extremely painful experience. It can be life threatening if you don't get to hospital fast. The paramedics were very good and gave me pain killers for the 20 minute rush to hospital where a catheter was immediately inserted. My point is this: be aware of the need to hydrate, even in cooler weather and do not neglect the symptoms of enlarged prostate. Better to get something done about it before you are forced into an emergency situation. I was fortunate to be referred to a urology surgeon fairly quickly and underwent the necessary operation - Trans Urethral Resection of Prostate (TURP) and I have been recovering quite well. No hammering steel for a few weeks yet though. So guys, NEVER EVER underestimate the value of a good pee, because if it stops altogether, you need to get help without delay!

-

I too have kept this photo for inspiration for a couple of reasons. One is that I have an unlimited number of rail spikes to work with, and the other is that it reminds me of our visit some years ago to Kootenay Forge in Canada. They were great people there and invited me into the workshop to watch the power hammer in operation and see their tumbler techniques for polishing finished pieces. Bought a couple of pieces to bring home to Australia. I have forged a few of the items in this photo but many I would like to try. The dragonfly is impressive and I like the toast fork with the knot. Haven't been on the forum for a while as I have not been well, but hope to get back into forging soon. Photos like this make me hope for a fast recovery.

-

What did you do in the shop today?

ausfire replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks, Das. Haven't been putting up much on this site lately. Seems I just do a lot of the same thing - mainly tourist stuff like bull head bottle openers, billy lifters, ram heads, troll crosses, fire pokers and the like. Still doing demos every day at the Village, but it's getting very hot here now. I guess you are preparing for some cold. Have been trying some different twists on the billy lifters. Here's one with a stairway twist. Anyway, Cheers from Australia and hope all is well with you and family. -

What did you do in the shop today?

ausfire replied to Mark Ling's topic in Blacksmithing, General Discussion

Just a couple of toast forks with bull twist handles. These use 8mm square bar, as I do a lot of these for campers. The 8mm is light, but a bit tricky for bull heads. -

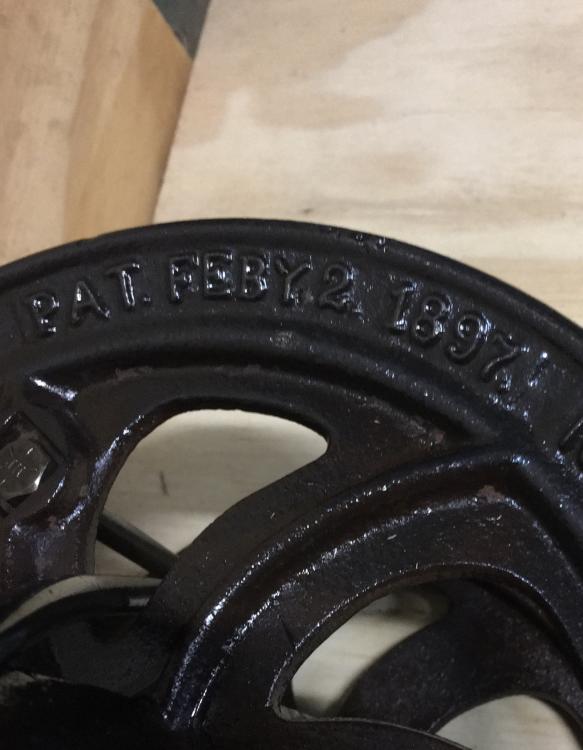

Thank you, Irondragon. I've done a few fire sets for others, but I might just keep this one at home. That 1897 casting on the base is a bit special and I don't think I would find another like that.

-

Just finished a fire set. The base is something off an old machine I found in the scrap. It’s patented Feb 2 1897 so there’s some history there. I wound a vine around the stem to add to the historic look. Four tools - poker, shovel, brush and toast fork, all 8mm round bar mild. Put the big bearing ball up top for a bit of bling! Putting this on from my phone. Never done it before. Hope it works OK.

-

wirerabbit started following ausfire

-

-

What did you do in the shop today?

ausfire replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished off a fire set today. The stand has a heavy base from the scrap pile, a long wrought iron bolt attached and a forged four-hook assembly on top. I added the bearing ball as a bit of bling. The four tools are poker, rake, shovel and fork. It's the first fork I have made with four prongs. Reason is that the guy who's getting this has four kids and they all want a toasted marshmallow at the same time! Stock was recycled 10mm rebar. -

What did you do in the shop today?

ausfire replied to Mark Ling's topic in Blacksmithing, General Discussion

It’s a fine thing you do, sir. The world needs more of that way of thinking. -

What did you do in the shop today?

ausfire replied to Mark Ling's topic in Blacksmithing, General Discussion

Forged a couple of lizards from old bolts. A loop in the tail makes a good pivot for a serviette hold down thing. The holder for the tail and the siderails are 6mm stainless. The base is a nicely figured piece of N.Q. maple. One of those happy sort of creations that make people smile. -

Yes, the T.P. Jones company was established in 1866, so I guess these were imported in the late 1800s. They have lasted well.

-

What did you do in the shop today?

ausfire replied to Mark Ling's topic in Blacksmithing, General Discussion

MacLeod, I'm not the right person to ask about tips for drawing out wrought iron. I can show you how to make nice toothbrushes out of it! I know you have to get it very hot to work it successfully and I have had mixed success with it. I do have a lot of it and I should learn to be more patient. It does have a very nice lustre when brushed up.