-

Posts

177 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jacob Nothstine

-

De-cluttering our hoards of 'stuff'I

Jacob Nothstine replied to Ohio Rusty's topic in Everything Else

Good article, I have been trying real hard to de-clutter the garage. I decided that anything I have not used in 1 year was gone unless it was real important, I also sold any doubles of tools this winter. It help me out to set a goal, new anvil this spring or pick one up at Quad state what ever comes first. Have a good size anvil fund now just waiting to fine one. My biggest problem is metal scraps, took a load to the scrap yard last month. Need to break down and do another load this month. -

inexpensive MIG welder advice

Jacob Nothstine replied to billyO's topic in Welding/Fab General Discussion

I picked up a HF 90 amp flux welder for $60.00 used on CL. They work fair, you get what you pay for. The trick is to replace the wire and tips with Lincoln brand . The wire that comes with the HF welder is pure junk. It would make a good weld but being a flux welder it was smokey and would leave flux and slag on everything. I did replaced it this winter with a Eastwood 135 mig welder with gas. Need to do some body work this spring, it's a lot nicer welder but everything out the door on sale with full tank was around $400.00 I did have a Lincoln 140 a long time ago it was a great welder but cost a lot more, I ended up selling it with my 65 Mustang. I was able to sell the flux for $65.00 on CL. -

These are great vise for flipping on ebay. I pick up a Wilton vise last year for $35.00 and sold it for close to $200.00 People collect them and will pay a lot. I use my machinists vises for holding bending jigs now and then, but a post vise is better for blacksmith work.

-

It's been a good month. My sister said she had some square tubing that was left in a house she is sell and asked if I want it? Showed up at my place with a trailer. Drop off 38 ft of 2.5" square tubing 3/16 thick, 16 ft of 2" square tubing. and a 3" round solid bar about 12" long. Was thinking of making a anvil stand not sure if 3/16 is thick enough for the legs, could double it up and make 2.5" x 5" legs.

-

I like Heller and older Plumb brand hammers.

-

I picked up 30 new hammer handles for $15.00 at a sale, but the best fine of the year so far was a scrap yard only 15 minutes away that sell steel for .20 lbs. picked up a 9" steel disk to make a bender out of and some 2" round 1045 for hammers, with all the new handles I will have to start making hammers.

-

Belt sander questions

Jacob Nothstine replied to /Y- Blacksmithing's topic in Finish and Polish for Knives

You might want to check out Kingspor's they sell belts in variety packs and leather belts. I have not tried the leather belt yet but a friend says they are great for re-sharpening tools. I have used my Kalamazoo 1 x 42 for sharpening tools and it works great. Taking large amounts of material off, it's a slow go. http://www.woodworkingshop.com/abrasive-belts/ -

Duck Hawk

Jacob Nothstine replied to Day.s F&S Forge's topic in Axes, Hatchets, Hawks, Choppers, etc

I like it, something different, made me smile. Was also thinking a fish hawk would be cool. -

Finished my winter lathe project. Back in July 2014 I picked up a Craftsman Lathe at a garage sale for $25.00 I cleaned it up and built a stand for it. To power the lathe I put a Baldor 1.8 hp 3200 rpm DC motor with a MC-60 variable speed controller . I can cut the RPM in half with the original pulley system and drop the speed to a crawl with the variable speed unit. I also found an original compound tool rest and 3 jaw chuck for turning metal. I just added a variable height dust collection system to it. The collector can be remove and move down for longer turns. I'm still testing it out but it's been a lot of fun. Project kind of back fire on me, ask my son if he wanted to forge the other day, "no I want to turn on the lathe" he likes making tops.

-

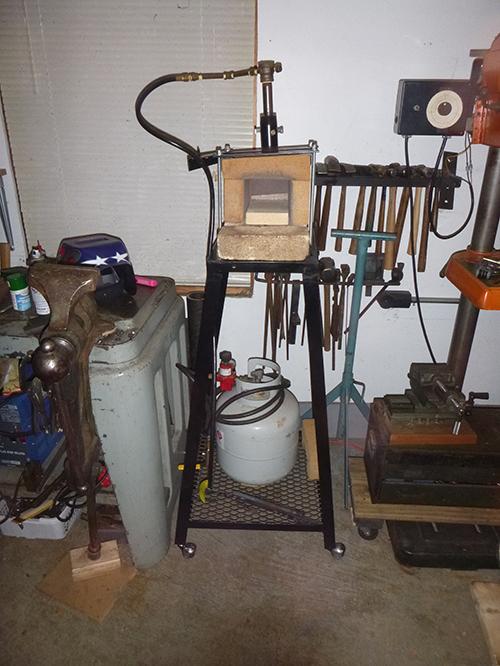

Here is my portable welding table, legs are made from a treadmill frame, top frame is bed rails. My forge stand was also made from bed rails. Hammer rack again bed rails.

-

Let it snow, I was just given a Snowblower (we have had no snow since I have got it ). I put new paddles on it and need to use it once, before I have to store it the rest of the year.

-

Nice looking RR Spike Knife, my son has made a few hooks will have to see if he wants to try one. Forge welding, I just pick up some Irionmountain flux for my gas forge and been happy with the results. For the bottom of my forge I have a 2900 F Super Duty Firebrick it helps protect the bottom of the forge.

-

Looks great, like all the extra room you have on the cart.

-

Protecting Table Top From Forge Heat

Jacob Nothstine replied to LibrariaNPC's topic in Problem Solving

Would a Black and Decker workmate work? Take the wood top off and replace it with 2 piece of angle iron. Clamp your forge in the middle sideways so nothing is under it. They fold up and are cheap used. I was thinking of making one into a welding table. Replacing the wood with steel plate. -

What is the oldest 'manmade' object you own?

Jacob Nothstine replied to njanvilman's topic in Everything Else

Kind of new for this thread, I have a Disston D12 from around 1860 and a Fray Brace I still use for woodwork from around 1880. -

Chop off saw vs bandsaw

Jacob Nothstine replied to blackleafforge's topic in Saws, bandsaws, hack saws, etc

I had a Chop Saw but never used it between the noise, dust and sparks. Would take it outside. The band saw is great for me I can cut metal when the kids are in bed sleeping. Don't have to worry about setting the garage on fire. The band saw does take a little more practice and tuning to get good results. You have to adjust it when going from tubing to solid stock. I pick mine up for $100.00 used and abused. -

This CL anvil started out at $130.00 and has been going down in price slowly, But it's gold plated and custom made for a blacksmith named Dave. If only it said Jacob :D

-

Problem with leaves breaking off the smaller I get.

Jacob Nothstine replied to bvbaird's topic in Problem Solving

If the 1" round was high carbon steel and you quenchant it in water, it could become brittle and can crack or break. I have made this mistake a few times. You can do a spark test to get an idea if it's high carbon. search high carbon steel spark test online. It would also be a pain to weld. -

Here is a video a friend sent me the other day of a brace made from re-bar. Not sure if re-bar would be a good material. But might help with design ideas.

-

8 dirty horseshoes and a welding jacket Just what I wanted

-

Great looking tool rack.

- 18 replies

-

- organization

- hammers

-

(and 1 more)

Tagged with:

-

Fun project. Going to give it another try this weekend. Had problems with the bottom of the shoe, think I need a sharper corner.

-

Making a Cyclekart with my son, it uses motorcycle wheels. Had to take a motorcycle tire off the rim so I could drill mounting holes. Didn't have the special spoon tool for removing the tire. So I used a holdfast. Normally used for holding metal down on the anvil. It worked great. I also used my post vise to hold the tire. Going to make a couple spoon tool before I put it back on.

-

In Michigan DTE Energy will pay you $50.00 for old refrigerators. I think that's 1 bag of coal or 2 LP refills for me. https://www2.dteenergy.com/wps/portal/dte/residential/saveEnergy/details/Rebates%20and%20Offers/Appliance%20Recycling/!ut/p/b1/jdHJcoJAEAbgZ8kD6AwzLMMRhICIbMOiXCggikgAoyLK0wdT5SGpbH3rqu8__N0gBisQN-mlLNJz2Tbp632P-QQT0wq5wHZNViBw7rG27voiAyk7gvUd2JJH2RH4EKojCBVHXxCsLYX_5eEPI8G_8gaIy6ye9nk9hVMMRcJCKDAIYUhEngOhkldX5bQsFFXx3sSZfPKfhzN3K4IySwdP8ivpunbVUJgMhsivUE_mh_1NXWbZJs0jbHBkCI-EMHm3zyh_rOyO8p5Wojajs8t21zemWPQvuDD3zc4xQtrLQ5UzchQFA6O0ViYL5SI_6TsqJ_WWY9yO1bokcVULRRMGRCD-3I_D87GfL2E5wAhBiX-Ax305jY5ADh3s-CqCmvAVfPOAD_DLhS29rTfgUAerYVN5ei89vQOPX3K_/dl4/d5/L2dBISEvZ0FBIS9nQSEh/