-

Posts

2,307 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jim Coke

-

Greetings , Dave, Ethan , others Allways up for visitors Welcome .. Just PM me in the spring .. Today 7 degrees and I'm going hunting for that lying ground hog.. Forge on and make beautiful things Jim

-

Greetings Bhutton, Any solid fuel or combination will work but you will find it hard to be consistent with your heat cycles which is important to a new smith . Find a single fuel that works for you and stick with it. Just this ol boys 2c. Forge on and make beautiful things Jim

-

Greetings Peter, I have several gas forges and my Forge master for 15years., You can forge quite well in the bright yellows . I agree it takes a while for it to reach temperature . The only adjustment you can make is the fuel. pressure with the needle valve wide open . You can bump up the pressure to 14 psi and it will help but watch your dragons breath , I never used it to bring metal up to forge welding heat because I preferr a coal forge. I guess it's possible but I would check with the Forge Master folks for their suggestions .. Iam interested in what you find out. Forge on and make beautiful things Jim

- 37 replies

-

- forgemaster

- gas forge

-

(and 1 more)

Tagged with:

-

Greetings all, My original intent was to drive the line shaft shop with a steam engine. I quickly learned that folks don't want to sit around and wait to get a head of steam up. I can drive all 3 main shafts with an 5 hp electric motor through a multi speed gear box or a John Deere LUC gas engine or off a PTO of the tractors. I posted my other blacksmith shops on the show me your shop thread .. The line shaft shop is mostly show and tell . Lots of fun.. A few IFI members have visited my shops and had a blast.. In the winter I live in a town about 25 miles away and close down the shops. I have a small shop close in town where I can forge and fabricate fun stuff.! Forge on and make beautiful things Jim

-

Craigslist Anvil Identification.

Jim Coke replied to michaelghorn's topic in Anvils, Swage Blocks, and Mandrels

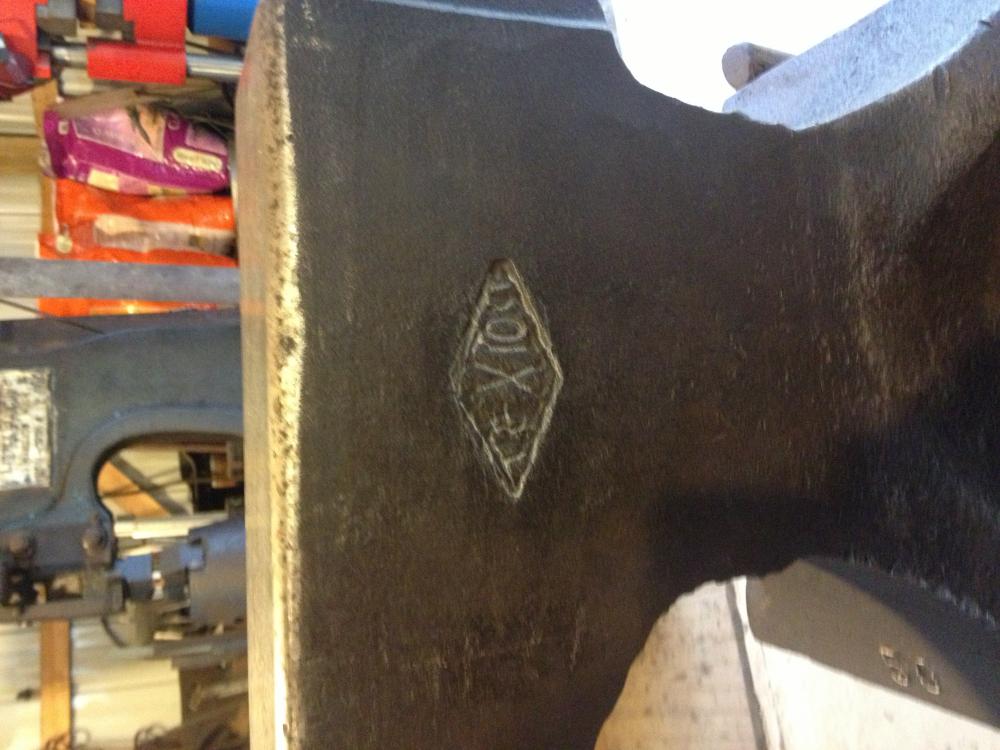

Greetings Michael, Great find.. Ya stole it.. You will find that it is of a point in production when they were built with a belt line weld and the whole top is tool steel . Not a plated anvil.. Love mine with an X too.. Forge on and make beautiful things Jim -

Greetings , That would be mine.. I posted pictures a while ago under my line shaft shop but they are lost with many others. TP the shop with the sign Iron Work is another building. I will try to post a few pictures. Forge on and make beautiful things Jim

-

Greetings Steve, I thought I designed cool tools . I like simple and functional .. Great job. I am sure many will benefit from your post .. Thank you for passing this forward.. Forge on and make beautiful things Jim

-

Greetings Bhutton, Just a few suggestions .. I would consider placing the fire pot closer to the center . I think you will find that you will end up with a lot of your fuel on the ground. You also have way to much hood and the design needs some help.. There are lots of references on IFI for side draft stacks., A picture of a friend at one of my forges that was a portable unit it found a home in the studio. Have fun with your build. Also your gas blower on the floor might be a bit much.. LOL Forge on and make beautiful things Jim

-

Hawthorn Power Hammer?

Jim Coke replied to Harlow's topic in Power Hammers, Treadle Hammers, Olivers

Greetings Harlow, This is second hand info.. A friend of mine stopped by my forge and wanted some info on a power hammer .. He said he has been trying for a long time to find a copy of Pounding Out The Profits and it seems it is out of print .. He was able to find a used copy but the price was sky high 400 plus. I have a copy and promptly put it in a much safer place.. Have fun with your new treasures. Forge on and make beautiful things Jim -

Need ventilation advice- lungs hurt

Jim Coke replied to Cardinal Knife's topic in Blacksmithing, General Discussion

Greetings Cardinal, Glenn.. Steve ,Charles , myself and others just want to see your 3017th post on IFI just to compare it to your first to check your progress.. We rag on ya cause we care. Be safe. Forge on and make beautiful things Jim -

How to add a horn to this ASO

Jim Coke replied to Quench.'s topic in Repairing and Modification to Anvils

Greetings Quench, Charles and DSW have suggested ideas for you .. I will just add an alternative suggestion to lock bricks to your set up . A simple hoop welded to a few bricks with a bottom wedge will work well . I have used this system for years with great success. Keep on thinking and you will do well. Forge on and make beautiful things Jim- 15 replies

-

- homemade

- improvised

-

(and 1 more)

Tagged with:

-

Need ventilation advice- lungs hurt

Jim Coke replied to Cardinal Knife's topic in Blacksmithing, General Discussion

Greetings Cardinal, If you move your LP pig a little closer to your forge you won't have to worry about air quality or for that matter the building not to mention yourself, DAAA Forge on and PYA Jim -

-

Greetings Sprig, If your friend has a wagon wheel ring roller that will do the job with ease cold . Mine has the groved dies for round stock . I have made many and 5/16 cold is no problem ., Good luck Forge on and make beautiful things Jim

-

Greetings Aus, The small vises are for filling small parts . Typically used by jewlers . They mount in a bench vise after mounting the part to be filed. The cutters look like valve seat cutters . The double ended adjustable wrench is a collectible and has some real value . The pliers / hammer is a leather working tool used by shoemakers. Great gift and have fun. Forge on and make beautiful things Jim

-

Greetings Jeep, Your into the project now . Glad you got the price thing agreed on.. You might consider a tight pineapple twist for the handle . It might just show up your Damascus well .. Pictures with your progress. Forge on and make beautiful things Jim

-

Greetings Jeep.. Price is king.. If your customer expects a Damascus replication and expects to pay slightly more than the off the shelf price. Well same old song .. Happened to me hundreds of times.. Calculate your time and material than ask your customer what is the budget. Watch your backside. Forge on and make beautiful things Jim

-

Greetings Jeep, looks to me like it was done with a ball end mill . The hardest part is to jig it up and hold downs. Forge on and make beautiful things Jim

-

Greetings XS, I built a special tube 3in in diameter 12 in long . Stainless inside than a copper insert pressed into a steel tube. One end is capped with a guide hole so you can slide in a 1/8 stainless rod with a hot dog attached. I constructed a special stand to set it on next to the forge.. Just pop it in the forge until dull red, remove, put in on the stand , slide in a squired hot dog and in less than a Minute. Lunch. Also I welded a hoop on top so the tube could be moved easily . One heat is good for 4 hotdogs . Tons of fun at a demo and lots of customers.. The main reason for this is to teach how radiant heat can be used. Sorry no Picts at this time stored away in a snow blocked building. Forge on and make beautiful things Jim

-

Greetings, Belongs in the museum with Josh.. To many other anvils out there for general black smithing . Forge on and make beautiful things Jim

-

Greetings Foxfire, If you look close you will see the skylight pattern on the floor. By design. My forge and hood are painted black so when you want a specific forging color just hold it up to the background.. Works for me.. These old eyes sure like a light on my work . Good luck with your new space. Forge on and make beautiful things Jim

-

Ian/Frosty I know that's a guy .. I ment to attract female artist to purchase the grinder..

-

Greetings Ian, Are you sure that isn't an advertisement for a an all purpose angle grinder for the female metal artist. Could be.. LOL Forge on and make beautiful things. Jim

-

Greetings Aus, From your picture the blower tube diameter has been stepped down at least twice before the tube .. I would consider a complete re-do . Your blower is far from a comfortable distance to the front of the forge and you must take a few steps and must be cumbersome to work with. I would consider positioning the blower than replumb to your forge . The pluming would end up square but should work just fine. Hope this helps. Forge on and make beautiful things Jim

-

Lawnjockey, The dementions of Studio FE 26 is 16x20. I built this shop in my basement and than assembled it over a two week process. Very functional but I get teased all the time because it has skylights and the interior is painted white with lots of light.. The center section with the skylights has a sliding door that allows for ceiling ventilation .. Most say that they could live there. Go figure. Forge on and make beautiful things Jim