-

Posts

842 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Rojo Pedro

-

-

Looks like a Vulcan to me but agree with Irondragon that the horn is very slim compared to my 100#. Also agree with Frosty in that it looks unused. Could the 63 mean 1963 and that it had a different pattern than my 1920 model? I think they still made anvils up to the late 60's

-

What's your latest blade look like? Post em and let us see.

Rojo Pedro replied to HondoWalker's topic in Knife Making

Nice work everyone. I have tried several coils springs and find them hit or miss when it comes to my crude heat treating methods. This one is from a spring that I know will get very hard in oil. 1-1/2” blade, 6” total length, unknown handle wood from my wood working brother. -

Nice one Will. Looks like my 1980 Duracraft. You wont know how you got along without it

-

Anvil Pattern/Style Question

Rojo Pedro replied to rich_c's topic in Anvils, Swage Blocks, and Mandrels

True statement on the hardys. You can make a block to replicate the square horn or a london patterns heel. There are times when a london pattern would be more useful than my double horn so there is probably no perfect anvil. -

Anvil Pattern/Style Question

Rojo Pedro replied to rich_c's topic in Anvils, Swage Blocks, and Mandrels

Good choice rich, Send pics! -

Anvil Pattern/Style Question

Rojo Pedro replied to rich_c's topic in Anvils, Swage Blocks, and Mandrels

Yup. What does the hornless anvil do that the horned one doesnt? Unless you are just straightening saw blades or strictly a bladesmith, I would go horned. I find both horns on my double horned to be very useful. Have fun regardless. -

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work everyone. I started a dishing hammer from an old bolt I found, a seax from a lawn mower blade and a little pendant. -

Didnt have a lot of time but wanted to try my new tongs and made these. Lots of fun and I realized that I need more tooling! Yay!

-

Nice one. Whistle while you work?

-

Nice looking axes. Please share pictures of your shop and welcome aboard!

-

Nice, good idea.

-

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

You will notice that there is nothing that rhymes with happy husband... :-) -

Good points FL

-

The sad part is that I believe it was intentional. Im guessing troll move meant to elicit the most responses. Even bad attention is good on the interwebs.

-

Looks good. Maybe a little shorter and bend the ball end over a bit. I like it

-

Or a good way to get a raise

-

Thanks John. Tongs have always made me nervous. It is good to know that I can now move the metal where I want to and look forward to making more.

-

Thanks Gents. I decided to forge down the big boss and flip the reins. I am super happy with how they turned out. I cut the rivet too short. Again. Works but barely. I made these to hold small tapers and it works a treat. Super fun and I will make more of this style.

-

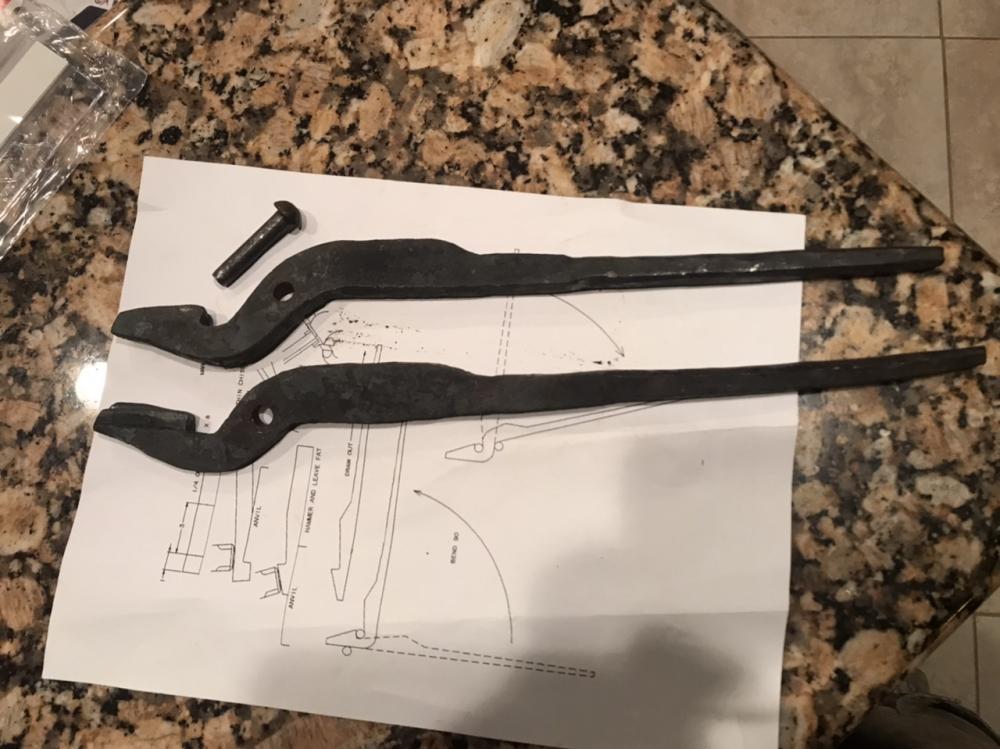

I wish I had seen the above post before I started but I tried a pair based on the drawing. 5/16 x 1 x 8” Would do it differently next time and may forge down the fat part behind the boss a bit. The three inch dimension is to much. All in all it was lots of fun and I will get a usable set of tongs. My first real successful pair.

-

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

Chimaera, I am a bit slow here but wouldn't angle play a role in the length of the cone? -

I will add my admiration for your leather work. Fit and finish looks top shelf.

-

woodworking shop (pic heavy)

Rojo Pedro replied to M.J.Lampert's topic in Building, Designing a Shop

Nice. I like the clear panels -

Scorpions are the worst. I've been stung twice, once in the arm. Very painful but it was done in about 15 minutes. Another on my foot and that one had me on the couch for 8 hours. Massive pain and sickness. Maybe a bark scorpion that time Funny thing was I got stung on the right foot and over the course of a couple hours, the pain went up my right leg and down my left and my left foot hurt worse than the right for awhile. Also was attacked by bees while exploring an old ranch house. We had to run for our lives and I counted 16 stings afterwards. I have been down a lot of roads in my life and I was never more scared then that day. If I was a bit older or crippled somehow, who knows? Very scary but I still love bees