-

Posts

844 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Rojo Pedro

-

M.J. my Kanca had a thick layer of clear coat on the face. It was very hard to remove with a cup brush. Have you removed the clear if it came with any? You will get better rebound afterwards My Kanca seems very hard to me. It has %95+ rebound in the sweet spot and has barely any marks after three years of weekends I have heard of soft ones however, maybe I got lucky. I have been happy with mine - P.S. thats a good price. About what I paid, with shipping, 3 years ago

-

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

I made a hook from a piece of 3/8” square, a bottle opener from half a RR spike and an anvil hold down from a piece of sucker rod, works real good. lots of fun and thanks for looking -

No name on the forge except No. 142 on pan and tuyere. In perfect condition save one missing bolt on the leg support. Belt drive blower no name but big and turns free. 1-3/4”x1/2” leaf spring pack and piece of cloth. All for $45.

-

Nice score. I use my mild chunk for cutting and punching.

-

Very nice. Lot of work there

-

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

My wife is a stained glass artist and made a gift for my nieces upcoming wedding so I took these… and a made a stand. I like nothing about it other than it works as intended (which I am real happy with) It was harder than I thought it would be. The stained glass is super special and a true work of art -

TFS Anvil vs. McLellan Anvil

Rojo Pedro replied to Lior's topic in Anvils, Swage Blocks, and Mandrels

I believe there are several anvil makers using ductile iron. It can be hardened to a degree supposedly. -

Daniel Moss Candlestick Challenge video

Rojo Pedro replied to jlpservicesinc's topic in Blacksmithing, General Discussion

Dollars US. The mistake was converting the orthometric height published in meters by using 3.2808... feet per meter instead of the proper .3408 meters to the foot. A small discrepency but it added up when starting from sea level like Billy said. This amounted to a 1 foot bust and caused the contractor to move 330,000 yards of fill dirt twice. It is a huge site. It started when producing the topo map and wasnt noticed until they went to tie in the sewer line and found our site was too high. Dosent sound like much but building height restrictions are very strict on the site. Very much a rookie mistake that should have been caught well before any dirt was moved or designed for that matter. -

Nice to see those beauties being used. I can't say which one I like best but that '27 Soderfors is really sweet. Thanks for sharing.

-

Daniel Moss Candlestick Challenge video

Rojo Pedro replied to jlpservicesinc's topic in Blacksmithing, General Discussion

An improper conversion from meters to feet just cost my company 1.4 million. Not blacksmith related just helping others to learn from our mistake. (The simplest double check would have caught it but no, they are understaffed and overworked) -

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

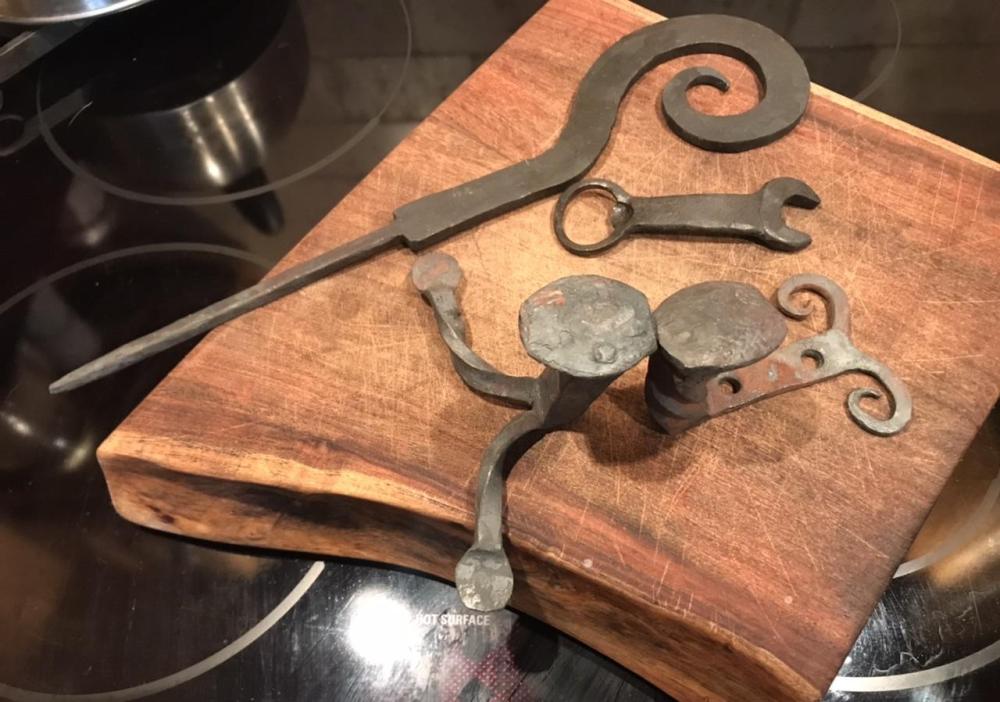

Been a few weeks since I’ve posted so heres a repcap…. yesterday I punched a couple holes using my favorite sucker rod punch. It holds up much better after I hardened it. then made a couple hooks last weekend I heat treated a 1075 kitchen knife (started to polish), a carving knife from an old file (got very hard), a cleaver and sugar knife from a leaf spring. All quenched in oil and tempered in my toaster oven and the weekend before just messing around mostly lots of fun and thanks for looking. edit: wrong thread. Meant to post in the what i did in the shop thread -

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

Looks good Arthur. Ver clean -

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

I love punching holes in stuff especially with tools I made Turned it into another bottle opener (give them away like candy) and started a little cleaver from a Studebaker leaf spring. Good times thanks for looking -

Most useful tool in your shop ?

Rojo Pedro replied to Glenn's topic in Blacksmithing, General Discussion

Bottle opener I know it goes against all known safety rules but I love to drink beer while forging. Never more than a couple three however -

Frazer's Corner of the Internet [photo heavy]

Rojo Pedro replied to Frazer's topic in Member Projects

Yes nice stuff all around. The hanger has just the right amount of too much! -

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

Very nice repurpose Chad. I will have to try one -

I have not but thanks for asking. I keep wanting to but I find that I would rather use my limited time forging. You have inspired my to go grab my kit and see how long I can get away with in front of the tv How about you? I love your steel sculptures.

-

Sichelschmidt und Schlasse (Sickle smith and lock)

Rojo Pedro replied to Zozon's topic in Anvil Reviews by brand

Nice one. Is that a date between the S's? Looks like 1941 maybe? -

Must Haves for a Gas Forge Work Area?

Rojo Pedro replied to RangerB's topic in Building, Designing a Shop

Nice. I like your treadle hammer too -

What did you do in the shop today?

Rojo Pedro replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes congratulations on retirement for sure! My plan is 6 years from today (yesterday I turned 59) -

Best Online Beginner Supplies (Tools/Stock)

Rojo Pedro replied to MaybeASmith's topic in Blacksmithing, General Discussion

Dont forget, steel can be found for free if you look around. Almost every house, yard, cabinet, road side has some rusty steel laying around. I hike a lot and find all kinds stuff. Even little bits can be forged into pretty things especially when starting out, just make sure to read through this site and learn to identify steel. In rust we trust. Have fun. -

Trouble seeing details in glowing metal

Rojo Pedro replied to IronChef's topic in Blacksmithing, General Discussion

Good one Mr. Anvil. -

Best Online Beginner Supplies (Tools/Stock)

Rojo Pedro replied to MaybeASmith's topic in Blacksmithing, General Discussion

Everything stated above. you can get started for less if you just want to try it. A wash tub or wash or box of dirt forge can work pretty well for next to nothing and you probably have the rest like a hammer and vise grips. an improvised anvil is the way to go until you get bit by bug and want to upgrade. You can get a decent propane forge online for a couple hundred. That and a bundle of Kens tong blanks, an improvised anvil and some scrap steel can turn you into a very good smith in short order.. Good luck, have fun and post pictures -

Safety third. cool link George