-

Posts

554 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by MotoMike

-

Ingenious ! thanks very much

-

JV would you mind showing me the whole chain hold down that you show in one of your pics?

-

good for a hot cut hardy?

MotoMike replied to MotoMike's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

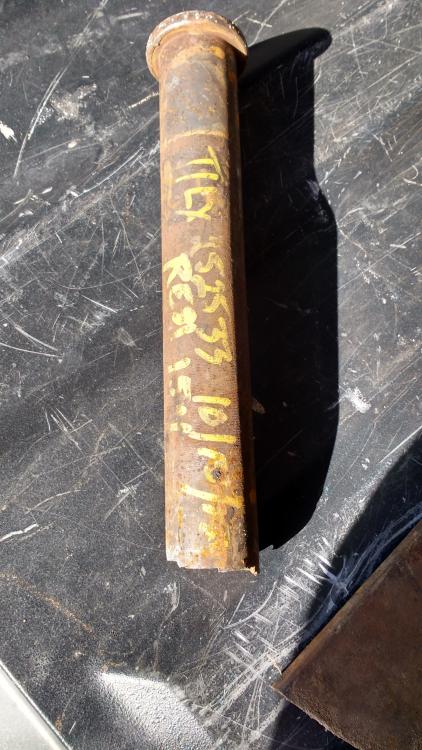

thanks Thomas. wondered about the clean break and that it did not appear to bend the piece in the breaking. Had me thinking it might have been harder. as Medium carbon will it work any easier than a higher carbon? that fat drift I made about wore me out. I will give it a spark test. I am not confident in my ability to discern what the sparks are telling me. will they photograph well enough for you to make an educated guess? -

Hi, picked this up at the scrap yard today. does anyone recognize what it is. about 9 inches long, 1.6 inches in diameter, shows a broken end. was in a pile of rail car suspension components. springs, trucks, spring seats and such. seems to have been machined as there are fine tool striations. will it make a good hot cut?

-

It is beautiful. That bad boy would wear me out.

-

When you say Reil burner is this the one you mean? seems I've seen that the jets Reil picked here are not right for butane. I don't think the reducer is your problem. I mistakenly put a 3/4 to 1 in mine and it works like a champ if a bit on the rich side with a size 59.

-

I live in a rural area, so shops that sell the things I needed to build my forge were not local. I tried to find an online source that had it all at the best price, but could not find that source. I got my rigidizer and Satinite from one source, my ceramic wool from another. I got the 1 inch 8 pound 2600 blanket from an ebay source that offered free shipping. I got all of it in very reasonable time. I got my Plistix from Wayne here on the forum. I built the burner before I started putting my forge together and checked in with the resident experts as I went along. My forge has been on line for a few months now and it works great. I stand on the shoulders of giants. Oh, If you care to see my progress, it is in my another newby thread

-

she looks to have low miles for her age. nice looking

- 10 replies

-

- arm & hammer

- age?

-

(and 2 more)

Tagged with:

-

I know there have been a lot of improvments since this burner hit the streets, but it is easy to build and brings my 300 +/- cu in forge up to welding heat and runs there at 4 or 5 psi. a little drilling and tapping but no welding. I forged the flare in my fire pit with the leaf blower idling towards the coals. I realize that I have made the claim that I followed the directions exactly, but recently realized that the reducer is only 3/4 to 1 inch. this resulted is a rich burn, but it still works well and is very stable.

-

First Hardy Tool Ever

MotoMike replied to Bayshore Forge's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

hey, thanks very much Brent. I think I'll try to make them so they sit firm on the shoulders. -

First Hardy Tool Ever

MotoMike replied to Bayshore Forge's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Thanks gentlemen -

First Hardy Tool Ever

MotoMike replied to Bayshore Forge's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

ressurecting an old thread. approaching the time when I will try my had at making some hardys. DSW - hardy seems to set fully on the shoulders. the others appear that they will sit in the hardy against the tapper. is this to make sure they don't move around? As Bayshore Forge mentions the taper would tend to get stuck in the hardy. what are the reasons/advantages/disadvantages of one way over the other? -

Hardy tool ideas

MotoMike replied to NickOHH's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

@Irondragon Forge & Clay Is drill rod H13 or similar? -

Looks finer than frog hair.

-

Thanks guys. I have the parts to make a "portable" post for it. time and weather allowing, I'll get that built soon.

-

Thanks Thomas. I wondered if the bracket attachment, a u bolt as opposed to the wedge locks, might have been a later design as well. seems like a better mounting system to me.

-

Thanks very much guys. I guess it is normal for someone to have gorilla handed the handle and put a bit of a bend in it. can you tell by looking at it when it was made?

-

Picked it up today. It is marked The Columbian Hardware co. Cleveland O. Made in USA. Jaws measure 4.25. Only Jaw Damage I could see is a chip on the top of each jaw. the faces of the jaws are straight and clean and all the inscribed lines forming a diamond pattern across them is sharp and clear. To me it does not appear to have been abused, the screw is in great shape. Did I do ok at $80.00?

-

Thanks @littleblacksmith Now I have hammer envy

-

Very basic back garden forge complete!

MotoMike replied to Patrick1992's topic in Building, Designing a Shop

very enjoyable account. very envious of some of those tools. Good work. -

Thanks Michael correct viking

-

Folded hot cut

MotoMike replied to MilwaukeeJon's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

ignorance alert. I thought that a hot cut in a hardy hole relied on the shoulders to take the force and the shank in the hardy hole kept the hardy aligned but that it should not be jammed in. can you explain why you want the tapered shaft jammed in there? Jon, I like the design and will consider it in for a hardy tool with a square close fitting shank. . -

Thanks Michael. I'll share all this with my buddy. If I cut off the hooks think it would be enough to make the test pieces?

-

My buddy wants to turn this into a pry bar. It is marked "drop forged". is it tool steel? How would you work it? what color for the initial working? after working anneal it? re harden it? Temper it? to what color? thanks in advance Mike

-

Very nice profile. a real beauty.