-

Posts

526 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Upland, Pa

Recent Profile Visitors

5,301 profile views

-

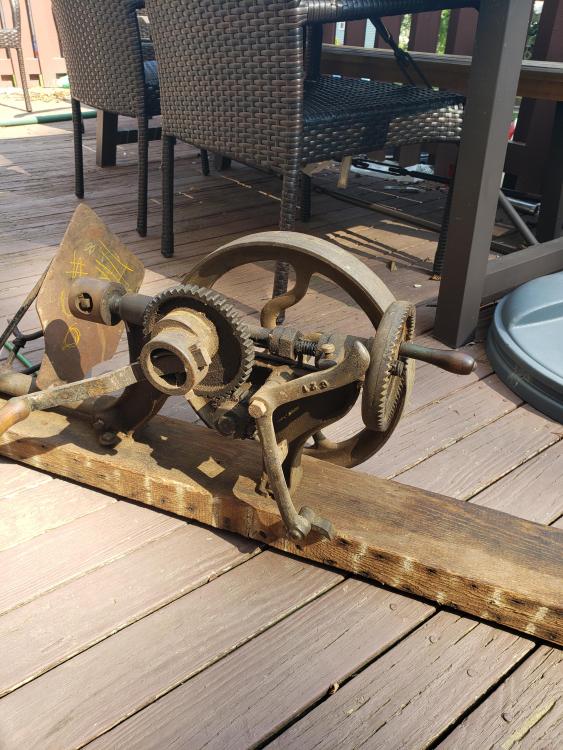

I figured it out, ended up being the pinion gear on the spindle, I used a thinner washer under the gear, I think it was changed at some point, gears mesh fine now and it runs smooth

-

Hey all, it's been awhile since I've been around here but I just picked up this post drill and have cleaned it up, reassembled and mounted it , but when cranking the handle the pinion gear on the crank and the smaller gear above it to drive the flywheel are binding at one spot , I loosened the set screw and rotated the flywheel gear and it changes when it binds . There is a little but of play in both gears should there be bronze washers in between to take up the play or do I just need to keep playing with the flywheel gear to get it properly aligned , it seemed to spin fine before cleaning.

-

What did you do in the shop today?

NickOHH replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished this little guy up. 2# carving axe , mild steel body with a 1095 bit insert 5 inch cutting edge, white oak haft -

What did you do in the shop today?

NickOHH replied to Mark Ling's topic in Blacksmithing, General Discussion

Been awhile since I've been around here, been a busy year, got sometime to play with some fire this weekend though, hammer and a handled hot cut , 4140 -

Typically a drift wouldn't have a handle

-

What kind of motor is it that your using a fan speed controller? Going to lose torque like crazy

-

Thank you for sharing your process with us, I will definitely be giving this a try very soon!!

-

Forge Welding Face Plate (pic heavy)

NickOHH replied to MarcyOHH's topic in Anvils, Swage Blocks, and Mandrels

Marcy is editing a longer video of whAt we got filmed , better video than what went up on FB. -

It weighs 144 , first number is while stone weights (112#) second is 1/4 stone weights (28#) and the 3rd is #s so it 112 +28+4=144 . You can use an angle grinder to smooth out the edges but I wouldn't be in a hurry , and if you feel you need to go light and just smooth them alil you can always do more if need be but putting metal back is much harder. A picture would help us know how bad ITIS.

-

Forge Welding Face Plate (pic heavy)

NickOHH replied to MarcyOHH's topic in Anvils, Swage Blocks, and Mandrels

-

Forge Welding Face Plate (pic heavy)

NickOHH replied to MarcyOHH's topic in Anvils, Swage Blocks, and Mandrels

Not yet , the plate was wide than the anvil , so it needs to be trimmed to final size and ground before heat treat. -

Dressing my forklift tine anvil?

NickOHH replied to thyNemesis's topic in Repairing and Modification to Anvils

The short edges could have a different radius on each of them the longer side could have say 1/8 on one end and transition into 1/4 or so inch radius on the other end ,matched on the opposite side -

Forge Welding Face Plate (pic heavy)

NickOHH replied to MarcyOHH's topic in Anvils, Swage Blocks, and Mandrels

Im not sure how many times it has been successfully done not in a manufacturing setting , but it isn't that many I don't think. It was an awesome project to get to be a part of, crazy Ivan was directing , with help from a couple other guys from PABA. Even wearing welding gloves , welding jackets and aprons , etc we all walked away with blisters and burns, the amount of heat was incredible. Took a good 2 hours to get to welding heat. We had a little delamination drifting the hardy to size after the 3rd heat , because we got it stuck , was way to short. But it was fluxed and re welded and it was fully welded by the end of the day. Welds were set with a hammer head attached to a long wraughy iron handle while it was still in the forge. The rest of the heats were 4 strikers and a gigantic flatter modded from a sledge hammer. The next one will be way easier and a water hardening steel will be the choice. -

Add charcoal and bit less air. I would want to add some sides that, maybe cut the barrel about 3 inches down and flip it over and tack it back to the barrel If your fire pot is just sitting in there . I would also take some clay or fire cement and smooth out the transition to the fire pot to make it easier to scoop the charcoal toward into the fire.

-

Looks good, the whole is a bit big for my liking, I use a much thinner punch with a v shaped tip with 4 facets on it, takes out a very thin plug , makes it nice and easy to drive through. Just make sure to get it good and hot and stop once you see the color fading a bit, but keep at em and they will get easier! Can't wait to see the finished hammer.