-

Posts

554 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by MotoMike

-

Thomas Powers, can you direct me to a pic of heat treaters tongs?

-

Growing up, Estwing was considered a premium hammer. they had some that the head and handle were integral with the handle comprised of stacked leather rings. They seemed to exude quality. Now I can't find one that does not have a synthetic handle or steel handle with plastic handle. I am sure they've put a lot of engineering into them, but I no longer have any excepf for a roofers hatchet that I really have no use for. Hmm is there enough metal there to make a hammer eye drift. Aschaefer, I'd probably round that peen too.

-

I’m ready for serious casting?

MotoMike replied to Hans Richter's topic in Smelting, Melting, Foundry, and Casting

Hans, thank you for your response. do I understand that the tip of the thermocouple is in the forge atmosphere near the exit but not directly in the flame impinging area? And does the tip stay there or do you only insert it for a reading? I tried your link but got lost. -

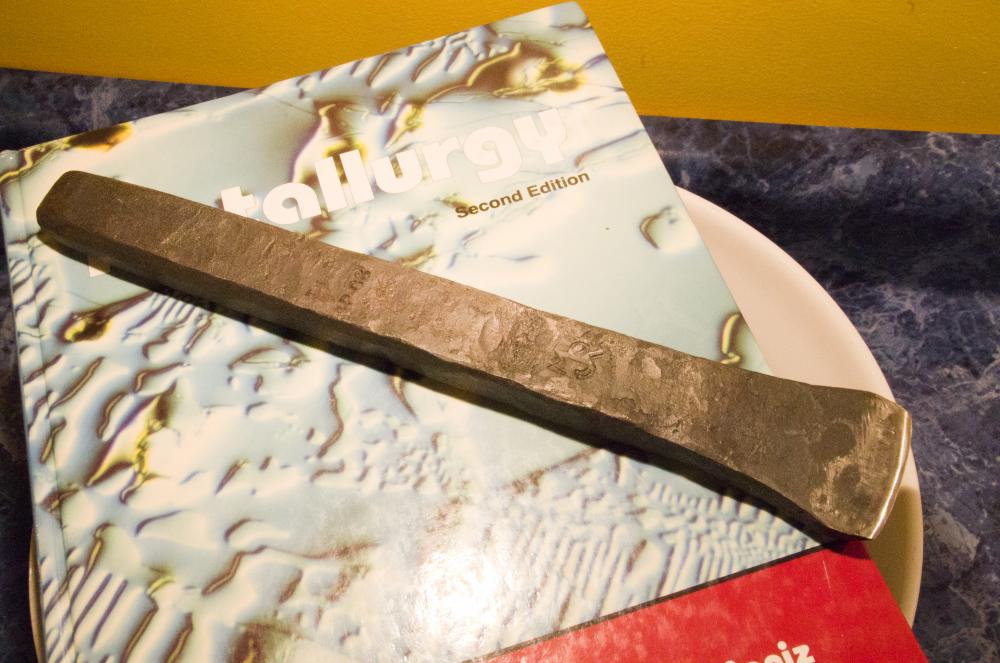

Those look like real monsters @Jim Coke these springs are much smaller. small one is 5/8 cross section and the bigger one is one inch. Made these from one of the smaller ones.

-

I’m ready for serious casting?

MotoMike replied to Hans Richter's topic in Smelting, Melting, Foundry, and Casting

Hans, Love that set up. Don't think I will be getting a foundry any time soon, but it is very interesting. Regarding your pyrometer. is the thermocouple the type that has the junction where the two dissimilar metals are at the end and a twist of two of the wire then going into ceramic beads to separate the wires? is the thermocouple in the forge atmosphere? is it left there or only used to take periodic measurments? could the end of the thermocouple just enter the forge and have a coating of refractory such as satinite over the tip to protect it from atmosphere? or would this alter the readings? -

Picked up 20 pounds of rail car springs today. planning on some punches, drifts and chisels. got a small one straightened. 5/8 cross section. the bigger one is one inch I think, so will be more fun.

-

Thanks guys. Linseed oil M

-

-

A Rail Spike Knife..... Ha just kidding Thomas

MotoMike replied to MotoMike's topic in Member Projects

Frozen forge - That is a beauty, Anachronist58 - Thanks very much. I envy you your weather. I bought a motorcycle in Alpine once. -

A Rail Spike Knife..... Ha just kidding Thomas

MotoMike replied to MotoMike's topic in Member Projects

Frozenforge - I think I got it pretty good. but as you say, a lot of work. funny thing about the rail spike. It must connect with people as I've posted several things on the blacksmithing for beginners site before and got 6-10 replys. this steak turner is at 155 and counting. surprised me. -

A Rail Spike Knife..... Ha just kidding Thomas

MotoMike replied to MotoMike's topic in Member Projects

Dave51B - that is a good tip. Does it take on a dark color? Thanks JHCC - Noted. thanks -

A Rail Spike Knife..... Ha just kidding Thomas

MotoMike replied to MotoMike's topic in Member Projects

Thanks gents. IFI is my "go to" -

A Rail Spike Knife..... Ha just kidding Thomas

MotoMike replied to MotoMike's topic in Member Projects

Thanks Irondragon. I think I have an hour and a half in that thing. started with a 4 pounder and once broken down a bit switched to my 2.25 rounding hammer. I suppose it is worth it for the experience, but wondering if people would pay what I need to make it worth the effort. It was fun though. Do you know if linseed oil can be used on items that will be in contact with food? Or should I use something like canola? -

-

I’m ready for serious casting?

MotoMike replied to Hans Richter's topic in Smelting, Melting, Foundry, and Casting

Well done Hans. I envy you. -

Beginner looking for feedback on 2-burner forge plans

MotoMike replied to Bruno Medeiros's topic in Gas Forges

Instead of ITC100 (expensive) I used Plistix that I got from Wayne Coe. I think it was 15 bucks and I have enough to do two more forges. The forge looks good and I considered making the track to hold the brick doors but found I like having porches front and back to set the bricks on or take them away completely. I might consider making the back hole a little bigger. I recently made a rack with hooks which was 19 inches long and I couldn't get it all in the forge because the back hole is too small to pass the hook once fastened. for refractory I used Satinite and made two layers totaling 1/4 inch. Probably not as efficient as Frosty's tee burner, but the Reil must be the simplest and cheapest proven design out there. -

It looks cool. very robust Shady: I too was surprised to see the idea that the knife has to be unblemished to be safe in the kitchen. there are plenty of high end chefs knives that have hammer marks and scale remaining. For those who appreciate that certain rustic aesthetic, Japanese chef's knives call it Kurouchi which I am told roughly translates to blacksmith finish. You will find it from slight to quite pronounced in all price ranges from cheap to as much as you want to spend. Aside from the aesthetic some say it helps with food release by breaking up the vacuum hard wet foods create.

-

9 year old granson at the anvil

MotoMike replied to MotoMike's topic in Blacksmithing, General Discussion

Thanks guys. I built him a rail anvil proper height. he likes this one better. the platform might be in the cards. -

-

What I took away from this was that the technique where you split the tong halves from one piece of stock using a hot cut chisel, it takes much less time as the reins need only be refined as opposed to being fully drawn out. If I had made a set of tongs with short jaws, they would have been done pretty quick.

-

Thanks SFC Snuffy. It is wiped down with boiled linseed oil while just hot enough to smoke it a bit. after it cools to warm I wipe off the excess. Shawn, I know. I have been thinking of making some more and putting them on a board. or possibly 4 on a post.

-

Shawn and Ben, Thanks guys. I learn something new every day.

-

Made from 1'x 3/8 flat stock. Used my new chisel to split the halves per JLP recent video on tongs. made the reins about 14 for the extra leverage and of course the jaws are different. two tools to make this tool were my new chisel and my new monkey tool. I will need to modify the jaws yet I think to allow easier entry into my forge opening. I'll get there.

-

Another tool from the Cave Man Forge

MotoMike replied to MotoMike's topic in Slitters, Punches, Drifts, etc

ThomasPowers; I hear you. I live in a railroad town and things such as hooks, crosses, bottle openers, letter openers where you retain the spike head so you know where it came from, have an appeal to the locals. Not to mention, some gifted smiths have turned out some elegant items from spikes. I know that the twisted spike knife will always turn up. they look cool, but are certainly impractical even if they were of high carbon.