-

Posts

255 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by aessinus

-

So while I was trying to get my new lil' anvil up to temp for quench, I got to thinking about what we use at work for epoxy laminate thickener. Glass microballoons, so tiny they feel like rubbing talcum powder between your fingers. btw, 3M's site nav blows - maybe that's why we use a local vendor of a different manufacturer.... Just where I looked 1st. Per 3M data sheet: "Thermal Stability Appreciable changes in bubble properties may occur above 1112°F (600°C) depending on temperature and duration of exposure" Just so you don't think it leaked out of my boots, here's the link to the data sheet that I finally located http://multimedia.3m.com/mws/media/91049O/3m-glass-bubbles-k-s-and-im-series.pdf . Anyhoo, reckon the little spheres would stabilize a refractory some & slow the HT without messing with surface durability much?

-

Conditions like this are why I refuse to let production folks use our tool fab shop unsupervised, even though the majority are company property. May I make a sign with your quote?

-

If the Hi-Lift has the bolt-on adapter, they make a really stout, if somewhat short, bar clamp.

-

Warning! Warning! Warning!!! Thermite

aessinus replied to WayneCoeArtistBlacksmith's topic in Safety discussions

In 30+ years in my industry (honeycomb) I've seen a couple of bad ones from the aluminum dust our bandsaws produce. Ist was a 55gal drum of powder that had been sealed with poly sheet & tape & stored out back the shop. The sheet allowed the barrel to get water in and made a galvanic circuit. When the H2/O2 recombined it blew a hole about 6' deep in the caliche yard & a whole bunch of the back windows. The plant manager wasn't happy. 2nd one was accumulated dust, rags, old airlines under a 5' x 12' 1/2"aluminum topped layout table. Gas axe sparks set off the crap under the table & the top started melting & finally caught. Before the guys in the shiny red trucks got it extinguished, the fire had gone through the roof 22' up. Different plant manager, but also not happy. Thankfully, that maintenace guy went on to another career path. -

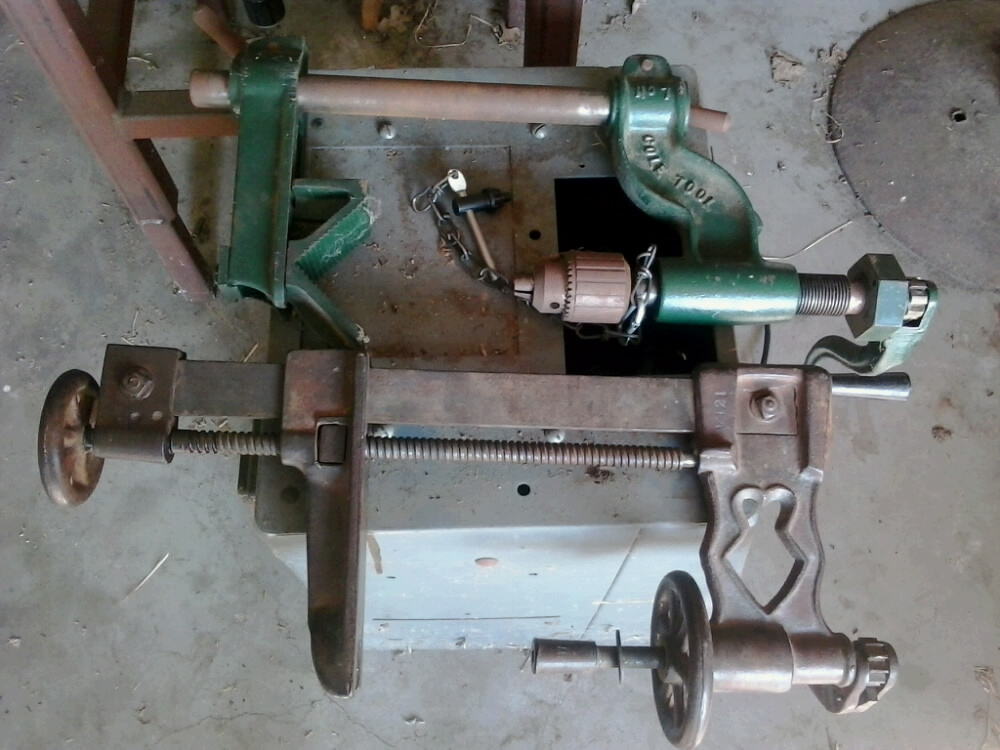

Cole #7 (purported by a g-uncle to be a cordless gate pintle drill) with 1/2"Jacobs chuck Older one is only marked with v121 ; has the taper square drive for brace bits

-

Really nice design! Gotta talk to our forklift rep about a couple of used tines. Rail plate for cheeks _ check Acme 1.5" - 5tpi screws/nuts _ check nice big base plate just begging for attention _ check Thanks for posting!

-

Bad on my google fu & memory, Frosty; I should have checked. They are easy to distinguish tho. Leaves are half spear, half heart, bark on a tree much bigger than my leg gets to be almost like short stubby thorns. Was mislocated to Pennsylvania (not AK, but too cold for native Texans) for 7 years & they even grow up there. Maybe you have them near the coast. Look for ugly, brushy fencelines.

-

"Slab" handles similar to Frosty (love that description, Sir), but hackberry instead. Those things grow any/everywhere across north Tx & I cut ém for handles at work & home from the fencelines & right-of-ways around all three properties. Carry a folding Bahco saw in my vehicle for that express purpose. Rather like stopping for roadkill rust. Apparently they are in the elm family, but they are tough enough to take the 5 year drought we just finished without issue. Make tough,springy handles. My goto 3# even has a slight curve so I can feel where the rounding face is without looking

-

Your 3rd photo looks suspiciously like Martin Forge on southside... Quite a few folks in the immediate DFW area. Like you I've only done round/square, square/round & making small machine piece for repairs at work. My son does show some interest making corkscrews & openers for his favorite craft brew store, & small machine piece for repairs at work. We,re the "dirty hand" engineers at both places.

-

Howdy! '83 myself & son is '13, both MET Ain't material science & metallurgy fun? Welcome aboard

-

I've used dropped acorns/leaves from the oak trees at work. Was shooting for a tanning solution for a hide & it stained the SS vessel pretty good. Patinates most carbon steels in a few hours, and your hands, dishtowels, floor, etc.

-

Show me your Bottle Openers!

aessinus replied to Arbalist's topic in Blacksmithing, General Discussion

Why reseal an empty bottle....? -

Show me your Bottle Openers!

aessinus replied to Arbalist's topic in Blacksmithing, General Discussion

So many great techniques & ideas here. The bbq fork opener should be worth a try to drop off at the craft beer store in town. Openers & corkscrews sell well there. Consider it borrowed. The bulldogs caught my eye because, well, they're buldogs.... <3 -

is it the smith (?) .....in the smithy ?

aessinus replied to SReynolds's topic in Blacksmithing, General Discussion

I have to wonder, are you polyglot, as well? Son is, but he thinks I only speak to materials..... -

Ever figure out the brace drive one? Or the piece immediately to it's right? Or your "tuning forks"? I got the balance right, but what a cool exercise....

-

Quite the haul. The monkey wrenches alone were a score for $30, especially the five "perfect" wood handled ones. You'll be pleased using the box-end wrenches. Are they all VLCHEK and/or Martin? Did you crop the vise intentionally or just being a tease?

-

Thanks, Hoss. I've had great luck so far.

-

14 pair. More expense to replace the bearings than to replace the entire unit. 1 1/2 pipe works as an axle. These oughta move a few things around the shop.

-

I waqs curious & did some searching. Your posts are the only ones I've found to include hackberry regularly. I've a good supply, both at home & work. The 3-4"growth along fencelines & the railway out back seem to make great hammer handles. Even at work they have held up for several years of abuse without breaking. Wedged & oiled seems to do the trick for keeping them tight for the safety inspector too.

-

looks like a lower platen from a small press.... See any signs of heating elements in the underside? Should make a grand tall layout bench or sharpening station after some vinegar, steel wool and oil/wax. Appears to have bosses in the support structure, maybe holes for press posts to take legs easily.

-

Which one to keep?

aessinus replied to No.4shot's topic in TPAAAT - Applied Anvil Acquisition Technique

Since they are both oiled up, stump mount them both on nice oiled wood. Reinforce the alternating monthly usage; keep the extra in the living room to remind you each morning to get to the forge & hit hot steel. -

Missed it by that much

aessinus replied to Michael Spaulding's topic in Anvils, Swage Blocks, and Mandrels

Yup, TPAAAT at it's utmost. -

So many spike ideas. One thought I've had is to use one of the lock washers that are used at the track joints. Spark test indicates more carbon than a spike. Anybody ever use one to put a bit in for the blade edge? That way the knife would truly be all RR. Just musing possibilities while it rains.

-

I've cut my own hair for 30+ years & used to cut the boy's 'til he went to a pony-tail. Roached a lot of mule manes , too. My Oster clippers have a snap-in blade system. The two screws are removed to polish the mating surfaces. All you do is remove the screws and polish the surface flat on a fine stone. Bought 1 set of replacements about ten years ago. I remember my grandpa shearing his sheep when I was a lad. He just used a bigger, coarser version, about 3-4" wide.