-

Posts

648 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Frozenforge

-

Assistance with Peter Wright Identification

Frozenforge replied to osbokev's topic in Anvils, Swage Blocks, and Mandrels

Somewhere between 1885 to 1910 as Matto said. -

Is it in the the truck yet?

-

I would be stoked to have an anvil in the kitchen!

-

The light insulating brick, used 6. Easily cut with a hand saw. I coated the interior with ITC 100 and blocked the rear opening just leaving a 1"x1.5" pass thru hole. I came across the turbo torch at a garage sale for cheap but a T burner would work fine. Lots of good information available at the meetings.

-

This is the forge I use the most. Without a power hammer you will only be able to work a small area at a time. You can build a brick type forge and a T burner with minimal tooling and no welding.

-

It would appear that it has been broken at the waist at some and the 2 holes probably had a metal plate to hold the top and bottom together. The large bolt in the bottom has also been added. It appears that the split has been welded and ground smooth. Unable to tell if it was full depth welded or just surfaced welded. A7101 would make it 1899 but it appears to have another number after the 1 which would make it 1907. Does it have a ring if you tap it with a hammer?

-

Picked this up a while back and finally got around to getting it set up. Rebound seemed low but I have always wanted a sawmaker just cause. After cleaning it up rebound is 50%. I dont know if sawmakers were treated different when it comes to hardening the face. I doesn't make sense that they would be but I don't know.

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Probably 4340. Most aircraft hardware is made for toughness. Better to bend than break and they rely on lots of smaller bolts than 1 or 2 big bolts for redundancy.

-

Chance to Connect with AK Smiths?

Frozenforge replied to AKHunter's topic in Alaska Blacksmith Association

Take a drive to Deep Creek and pick up the free coal off the beach. Not the best but some of the chunks are pretty descent. Last time I got down there there was a piece the size of a car that had broke off the seam and fallen down the bluff to the beach. Price is right! I know there wete some machine shops that did alot of oil field equipment fab and repair. Those shops often have remnant pieces of alloy steel. -

Here's to a speedy recovery with no lasting symptoms. Home, friends and family are good! Best Wishes

-

Peter Wright Anvil

Frozenforge replied to Beatsy' s Forge's topic in Anvils, Swage Blocks, and Mandrels

Based on what I would pay isn't really applicable as up here in Alaska as anvils as rare as palm trees and so priced accordingly. The Peter Wright up here would be sold on the same day. The Fisher (assuming it is in fair condition and actually is 300lb) at that price would be sold on the 1st phone call cause I would hopefully be the first caller! The saddle area on an anvil really is nothing to worry about unless it is extreme and has effected the structural integrity. About the only anvil I would not recommend as a first anvil would be a cheap cast iron that you had to pay for. Other people on the forum rarely pay more than $1 per lb. Be respectful, offer what you are willing to pay and gracefully accept the answer whatever the outcome. -

Peter Wright Anvil

Frozenforge replied to Beatsy' s Forge's topic in Anvils, Swage Blocks, and Mandrels

Need a picture of the logo and anvil to get a rough age. Peter Wright didnt serialize or date their anvils. If its in average condition and based on your location it is probably worth around $3 per lb. But of course it is really worth what ever someone will actually pay! -

If you file a little notch or 2 in the hole prior to installing it will crimp into the notch and help prevent the spinning nutsert.

-

Approximately 1912 farriers anvil, should be the one piece top half style so no worry about face delaminations. Looks like it's in good shape. I would suspect it has a really good ring when struck!

-

Basically anything 600 or below would be a good deal, 600 to 1000 would cover the average to high average. Above 1000 would be collector pricing or someone who wants it bad! That should have a one piece upper half and there shouldn't be any face welds to delaminate. Does it ring when tapped with a hammer? A clear ring on a Trenton anvil usually is a good indicator of structural integrity.

- 19 replies

-

- anvil

- trenton blacksmith

-

(and 1 more)

Tagged with:

-

Approx 1939-1940 it should have a weld at the waist joining the upper and lower halves.

- 19 replies

-

- anvil

- trenton blacksmith

-

(and 1 more)

Tagged with:

-

Yes it is a Trenton and that is how they were made at that time. There is a picture in AIA of one being welded at the waste during production.

-

Need help identifying an anvil

Frozenforge replied to Fredrich Legnemark's topic in Anvils, Swage Blocks, and Mandrels

Looking in AIA there was not a Wilkenson logo that Mr Postman had recorded that looked like yours but that doesntmean much other than making it difficult to roughly place a date. One possibly is that it was a custom order done by Wilkinson? -

Does appear to be a more specialized application. The main arms look about the same as what a 4 or 5 inch vise would have. I wouldn't do any hammering or heavy clamping with it. Definitely a collectors price. Jakeshop. Really like that setup, solid but not totally immobile.

-

Hard to say, I wouls say yes on the air side anyway. I knew I was making too many changes at once but I figured what the heck? My thought was that if the propane velocity is high enough to really pull alot of air in with it then you could have a tighter forge and decrease the heat loss.

-

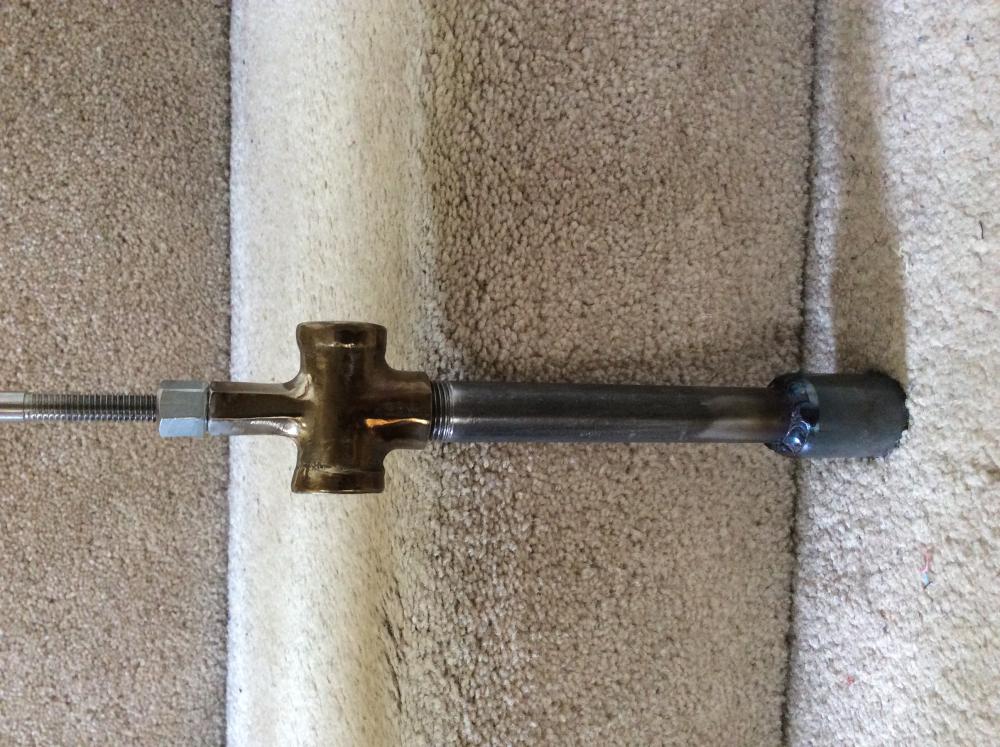

I have a 1/2 Experimental T burner that I bored out the threads, cleaned and smooth it all out. I have the mig tip screwed into a threaded tube to enable easy adjustment. It has a nozzle comprised of 3/4" as the step to 1" pipe. Tried a .025 mig tip. Best way to describe is that it has too much velocity?? so it will only run between 3 and 5 psi. Anything above 5 blows the flame out unless I choke off over half the air. Moving the mig tip in or out seem to have a limited effect on the mixture. Sorry I don't have a picture of the flame but it is well centered and has a nice form at the lower pressures. Have not had much time to experiment with it much more lately.

-

170# Trenton Anvil Questions

Frozenforge replied to Michael Gendron's topic in Anvils, Swage Blocks, and Mandrels

Based on what I can see for condition, and even though we have no idea where in the world your are from, at that price it is well worth the risk that it might be soft. -

Looks like a Vulcan to me. Need a better picture of the side when horn is pointing to the right.

-

Need a picture of the logo stamped on the side. If there isnt a logo visible sometimes you can get a rough idea by the shape

-

So how does one gain information to attend the upcoming clinic? From bits and pieces of other posts I know its in mid June. I was planning on making the last meeting but my beer league hockey team made it to the finals so I was playing hockey. (We lost but it was a close game).