-

Posts

2,617 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by David Einhorn

-

ABANA 2018, Richmond VA, starting 6/27/18

David Einhorn replied to Stash's topic in Events, Hammer ins, Where to meet

Going down Wednesday. If I understand the schedule, Wednesday is basically set-up, actual demonstrations start on Thursday. I could be mistaken, but I don't think so. -

May 27th, 2018 will be the third meeting of the blacksmith group of the Williams Grove Historical Steam Engine Association, at 1 Steam Engine Hill, Mechanicsburg Pennsylvania. Interested parties of all skill levels are invited. Please wear safety glasses, and bring what other food, drinks, chair etc that you may wish for your comfort and safety. There are food vendors on the Steam Show grounds every Sunday, selling food and drinks. Every Sunday is a flea market, and the vendors are located along the two sides of the flea market.

-

It's sort of like asking what is the best vehicle to purchase. Depending on who you ask, you will likely get a different answer. If you are a young person "the best" may be to go to a college/university for a degree in design where they also have a blacksmithing program.... also learn German, French and Italian fluently so that you can, after the university, work in various shops around Europe. If not that, then start with the closest blacksmithing school, practice, then take specialty courses at whatever blacksmithing schools are offering courses to add to your skills. All said and done, try a couple of courses to see if blacksmithing is something that you really want to do.

-

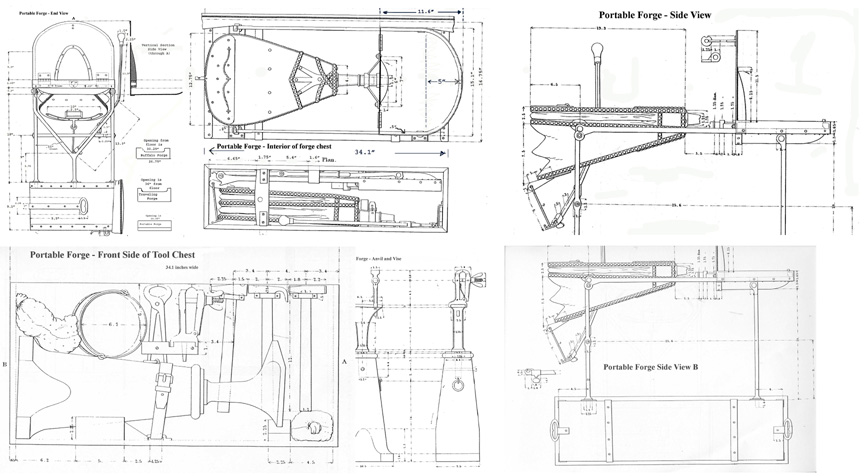

U.S. Army (Cavalry) pack forge

David Einhorn replied to Irondragon Forge ClayWorks's topic in Solid Fuel Forges

Actually, below are official U.S. Army diagram(s) of the U.S. War Between the States (aka Civil War) pack forge. The above forge is post Civil War and not a pack forge. Would love to have a forge like the one under discussion but all Civil War forges were side blast forges and used bellows. Blowers were not used by either army during the War Between the States. -

On March 25th, we had a very successful meeting of folks in the blacksmith shop at Williams Grove Historical Steam Engine Association in Mechanicsburg, Pennsylvania. Both beginner and intermediate skills/information was shared with attendees. Please PM me with your email address if you wish to be added to list for updates to what is happening at the Blacksmith Shop at Williams Grove Historical Steam Engine Association. Blacksmith group meetings at the Williams Grove Blacksmith shop are planned for last Sunday of each month. (Please to not use the forge before you pay dues for the Williams Grove Association and sign their release form.) We will be developing an additional release form for smiths. Stay tuned for any updates. General Proposed Format For Meetings 8:00 am - Doors open. General discussion follows lighting of the forge 9:00 am - Beginner forge techniques and practices 12 Noon-Advance techniques demonstrations and discussion Demonstrations followed by Steam Show Association members time at forge Gates to Steam Show grounds close around 14:00 On April 29, 2018 Williams Grove Blacksmith Group Meeting On May 27, 2018 Williams Grove Blacksmith Group Meeting On June 24, 2018 Williams Grove Blacksmith Group Meeting On July 29, 2018 Williams Grove Blacksmith Group Meeting

-

How did you find your first anvil?

David Einhorn replied to AggieBlacksmith's topic in Anvils, Swage Blocks, and Mandrels

Was helping a friend many many years ago renovate his sister's house, and mentioned it to him and his sister. When her husband got home, she told him I was looking for an anvil. He said he has one in his VW bus and sold it to me. -

Some people build different forges, each for a different type and size of project, and efficiency of how much gas is used for the project, and in some cases how the heat is swirled around instead of directly *at* a project such as a knife. ...... Of course we know that a TV show would not design forges to make forging more of a challenge and to increase the temperature in a room... hmmm. :-)

-

How about forging a Cherry Blossom (or other flower from one of those regions) ? If you can find an artificial one from a craft store, you can then take the artificial flower apart and use the parts as a pattern for making pieces of your forged Cherry Blossom. By Googling on "Cherry Blossom Artificial Flowers" I found that people are selling them.

-

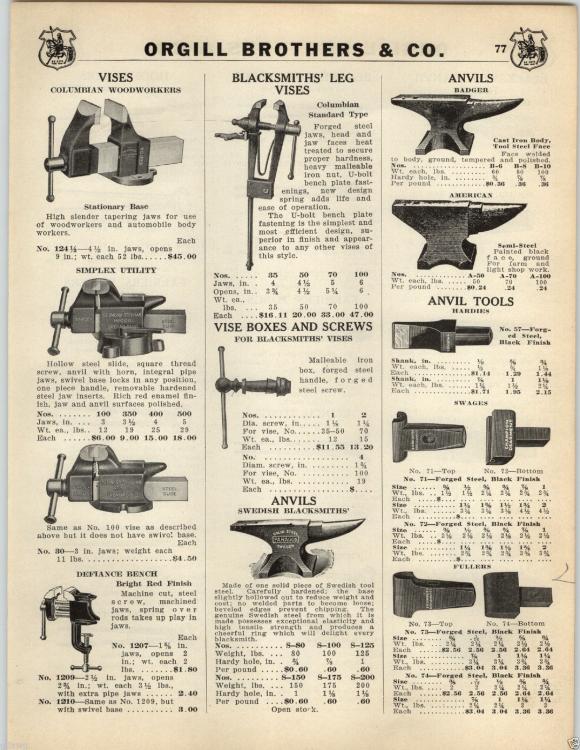

Well.... maybe not a Frankenvise but possibly one with a purchased replacement box and screw set. Replacement box and screw sets were sold a bunch of years ago by Centaur Forge, and prior to that replacement box and screw sets were advertised as available. ..... Also, check for a square ridge along the top of the box that may or may not match a notch on the inside top of the hole where the box passes through the back of the vise.

-

Which sword are you making? One of these? Civil War Army Swords; A Study of United States Army Swords from 1832 through 1865 Hardcover – February 15, 2008 by John H. Thillmann (Author)

-

I've built several types of work tables tailored to what I plan on using them for. Here is my latest work table built for experimenting on building gas forges, with storage cabinets for tools and parts as well as racks for use either with hot stuff or tooling.

-

Ancient iron was derived from meteorites

David Einhorn replied to Origins of Iron's topic in Historical Blades

What about bog-iron? Wasn't that also found way back when? -

Try this thread:

-

Bart Jam Dao.. The Wing Chun Butterfly Swords

David Einhorn replied to Louie DeBono's topic in Historical Blades

You may like books by Fumio Demura such as : Fumio Demura's: Karate Weapons of Self-Defense: The Complete Edition -

Student doing a project needs questions answered

David Einhorn replied to peggieweg's topic in Everything Else

1. Whats your name and where are you from? See name to the left of screen ..... from my mom 2. How did you become a Blacksmith? took a course 3. What do you like most about your job? hobby, not a job, ..... I like that people don't spit on me any more 4. What do you dislike about your job? retired from counseling in a mental health clinic. I really disliked it when people spit on me 5. What do you do on a day to day basis at work? retired ..... blacksmithing is mostly about working hot iron in its plastic form, and not focused on welding 6. Do you have any welding background? took a course in arc/gas/mig welding and two courses that involved forge-welding 7. What advice would you give to a beginner welder? take a course .... and if you want to do blacksmithing then to take some courses in blacksmithing Is your teacher confused about whether blacksmithing is about forging hot metal in its plastic state,..... versus a focus on modern welding careers? -

Definitely a lot of work. I humbly suggest several coatings of linseed oil to help prevent further damage to the wood, ..... and new valves.

-

A lot of good advice has been provided. As someone who has for a number of years, and many years ago, built sets for both school and community productions, my experience is that even adult actors will find a way to hurt themselves in unexpected ways. In no way, based on past experience, would I provide any actor, adult or child, with a sword. Twist a balloon into a sword and the kid will immediately start waving it around and likely hitting people with it. I am not a lawyer, but legal advice that I received from a lawyer was that absolutely no release form will protect a person from being sued.... period.

-

As Mr. Stevens has mentioned, I have built two side blast forges. There were four documented side-blast forges during the U.S. War Between the States [WBTS] used mid-1800s. All four forges were open box structure with the largest one used by the navy which was an open approximately 2ft by 3ft metal box. During Sherman's famous march to the sea, his blacksmiths simply stuck the nozzle of a bellows through a hole in the side of whatever wooden box was on hand, and covered the bottom of the wood box with a layer of dirt. European side-blast forges that I have seen pictures of, also were open hearths without tuyers, just a box with a nozzle sticking into one side. The sides of the fireplaces were to just keep the fuel from falling onto the ground. Comparing the two side-blast forges that I have built, the one forge has about two feet of 2-inch copper pipe running from the fireback to the bellows, while the other has about a foot or less of schedule 40 black pipe. While the two foot long copper pipe works wonderfully well, the short steel pipe heats up and I have to wrap a wet cloth around it to prevent heat transfer to the wooden bellows. Someone posted a water tuyer on the Internet that prevents the heat transfer. So to make the forge with the iron pipe work properly, I will either have to lengthen the air pipe, and possibly insert a copper pipe, .... or will have to build and install a water tuyer. Below are some sample side-blast forges, from the WBTS. So in summary, all the old side-blast forges that I have seen or built are basically wood or metal boxes with an air pipe/nozzle poking through the side of the box. And the main consideration, in my humble opinion, is whether there is heat transfer to the device providing the air supply.

-

Project ideas for the novice blacksmith?

David Einhorn replied to RobtheSmith's topic in Blacksmithing, General Discussion

I have all three of Mr. Darnell's books, “Forging Colonial Ironwork” books I, II, and III. His books are “comb bound”, and hand drawn and hand written. Each book contains step-by-step instructions for making a fairly large number of Colonial Period blacksmith projects. If you are looking for a library of Colonial projects, then I recommend purchasing his books...... I also recommend purchasing the book “Early American Wrought Iron by Sonn”. -

Ah yes. About 20 minutes away. Spring Grove... also known as Papertown. :-)

-

Welcome from south-central Pennsylvania

-

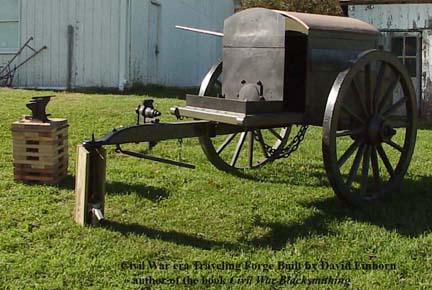

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

I don't feel young. I'm always happy to help anyone that I can, especially anyone working on gear for historical presentations. As for some corrections, such as casting the brass parts for the pipe and joint is likely to be forever beyond my ability and reach. Having already spent 11 years researching, and four years working at building it averaging 2 hours, 7 days a week, that comes to around three thousand hours of of physical labor. Beyond doing some repairs, rewiring the trailer that hauls it, and a box to support the anvil, that is pretty much my limit of what I can realistically invest in the project. My advice to someone wanting to build one is to purchase the wheels, as that would save them at least 1/4th, or more, of the labor hours. -

Civil War era blacksmith wagon

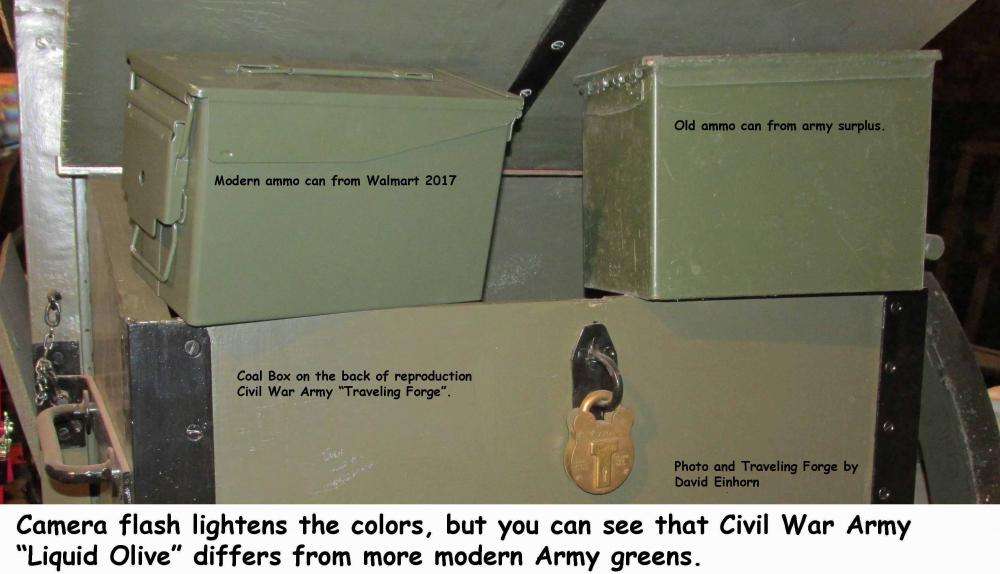

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

This photo (camera flash) tends to lighten the colors, but you can see that there is a difference between what the U.S. Army in their 1860s Ordnance Manuals called "Liquid Olive" green and more modern greens. If you look on historically oriented forums you will find discussion(s) of how U.S. Army green has changed from the War Between the States, to WWI, and WWII, etc. Differences more noticeable side by side so as to be compared. Yes, during the War Between the States (WBTS) blacksmiths used what was on hand, often a discarded barrel or box. I don't claim absolute authenticity. For example, I would likely have to build at least 200 No.1 Artillery wheels to develop the skills and accuracy, to make a wheel that was 100 percent authentic. I also used two-inch copper pipe for the tube from the bellows to the fireback, if anyone would like to cast the pipes, and connector, in brass and donate them to my forge, I would be happy to accept them, as that is beyond my finances, and skill level. See authentic Army 1860s pipe diagram below. :-) .... I would also accept a donation of the correct sized and period correct powder keg or barrel to rest the anvil on. I would also accept the donation of a period correct Limber-for-field artillery use (and Limber box) to *safely* rest the lunette on instead of the incorrect prop. :-) -

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

The color is correct. I found the guy that helped the Park Service with mixing period chemicals according to the 1860s official U.S. Army Ordnance Manuals.... had him mix me a batch, and provide me with a copy of the mixing machine instructions. Took a sample to Lowes and got mixing machine instructions for their mixer also. Details are included in my book.