-

Posts

2,617 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by David Einhorn

-

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

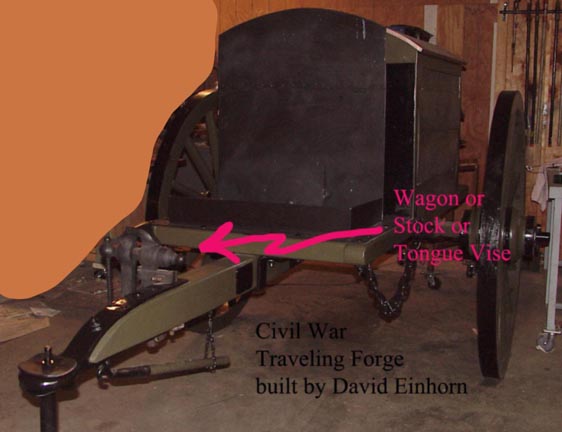

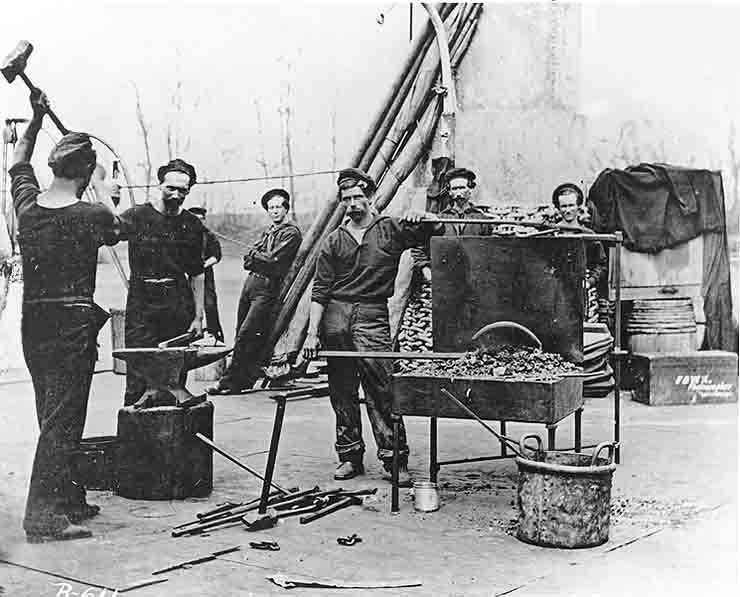

This is the forge from the other side. You can see the fireplace and the fireback. .... Doesn't really matter what I paint or otherwise, some people will always find something to complain about. The people who never have a complaint tend to be those who either have tried to build one, or have succeeded in building one...... partly because in looking at the attempts by other people to build one, so far my forge seems by far to be the most accurate. My goal was to construct it so that a smith from the 1860s Army, when walking by, would not do a double-take. When before the public, I wrap a tent half around the prop, and other canvas over stuff on the ground, so that it is not seen. -

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

No there were no military specs for anvil stands. The used whatever was on hand. I spent an average of two hours a day, for four years building the forge, wheels and tools to build the forge and wheels, and I lost track of how many thousands of dollars I spent on it. The anvil stand is wood, and all that I as an old man can move with difficulty. -

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

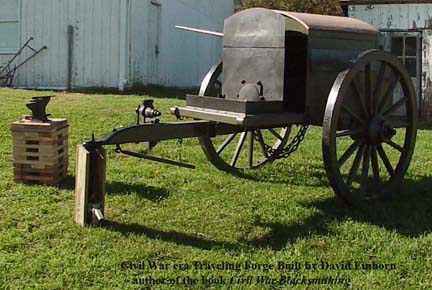

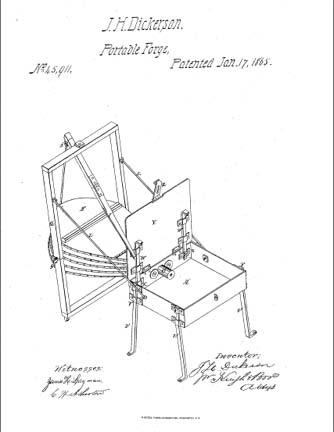

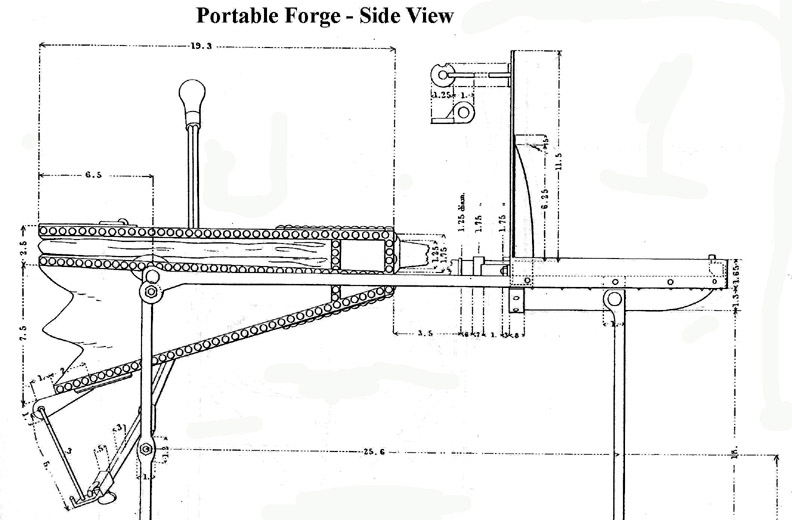

Here is my Civil War Traveling Forge.... reproduced using a copy of the diagrams provided to factories by the U.S. Army during the 1860s, and also using information from period Ordnance Manuals. The wagon vise and anvil are correct to period specifications and possibly from that period. The cast iron fireback and the cast steel lunette were purchased from Museum Collectors Specialties who made those parts according to 1860s Army specifications. I even built the wheels, and the tools to make the wheels, myself. -

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

Antique Ordnance Publishers publishes copies of the period U.S. Army drawings for use by factories in manufacturing equipment for field artillery use. http://gunneyg.info/html/AOPCatalog.htm -

We had a rifle club, and a rifle team, and a rifle range in the basement of the high school when I was in school there.

-

I have *two* of that exact same model..... but I also have a wooden box with pairs of replaceable jaws.... and both vises have adjustable-height upsetting blocks. Very nice and very useful for repetitive bending and heading/upsetting. One could also make jigs to fit on the jaws to allow for other quick clamping and bending. The upsetting block(s) are moved up and down the teeth on the inside of vise, so that if you are bending or upsetting a round or flat bar you use the appropriate jaws, set the distance between the top of the jaws and the upsetting block, heat the irons, sit the bar against the top of the upsetting block, step down on the lever to close the jaws, then bend the bar.... repeat as often as you have bars for the same bend or upset.

-

Sometimes a smith makes a single tool for a special purpose that no one has made before or since. What is left is for us to wonder what those tools were used for. If I had to guess, my guess is that the pointy end was driven into wood, and the tenoned end was to support something with a matching square hole.

-

Sounds like it should work ok... Just make sure that you have good airtight chambers and that you valves are at least 10x10 with good seals, and snap open and close.

-

Mathematics in blacksmithing

David Einhorn replied to Ferrous Beuler's topic in Blacksmithing, General Discussion

I recommend the book, "The Value of Science in the Smithy and Forge" by W H Cathcart as the book has formulas that I have not seen anywhere else. Available free on Google Books and elsewhere........ or in hard copy as a reprint. -

Things to do with wrought iron

David Einhorn replied to Bill in Oregon's topic in Blacksmithing, General Discussion

Wrought Iron There are different grades of wrought iron. Low grade wrought iron has given wrought iron a somewhat less than stellar reputation that higher grades of wrought iron does not deserve. Higher grades of wrought iron forge very nicely, the only comparison I can think of is that forging higher grade wrought iron is like forging butter, because it is soft, forges easily, and *does not splinter*! You will find higher grades of wrought iron in more expensive products such as high-end kitchen utensils, and low grade (less processed) wrought iron in things like wagon tires. Low grade wrought iron needs to be forged at a much higher temperature than high grade wrought iron. I have heard many times that people working wrought iron work the iron at or near welding temperature in order to be basically constantly welding the wrought iron back together. Can the low grade stuff be refined by hammer and heat? That is a very good question and one that I have wondered about. Higher grade wrought iron is higher grade because it has been drawn out, stacked, forge welded and worked that much more than low grade wrought. The more times it goes through the cycle of being stacked, forge welded and then worked, my humble understanding is that it becomes a higher grade. It would be an excellent experiment to experiment with low grade wrought to see if and how one can convert it to high grade wrought iron. Sounds feasible, but I don't know anyone who has tried that. Old "wrought iron" the material, not the process of final shaping, is a wondrous material. In the process of making the material called "wrought iron" the sand that was used as a flux was included in the metal. As old wrought iron oxidizes, the oxygenation process eats down into the item until a glass surface is revealed. If the glass surface is not damaged, the glass acts as a preservative preventing further rusting. Since the glass is not distributed evenly, the resulting surface tends to be textured according to the distribution of the glass flux within the metal. ..... In terms of tool history, a fairly recent theory suggests that iron was used for tools much earlier in history than previously thought to be the case, but that due to iron's nature to oxidize, has not survived as well as brass and copper tools. Back in 1973, when I took an introductory course in blacksmithing, decent wrought iron was still being manufactured and was readily available to purchase. Good grade wrought iron was wondrous to work with, as it was softer due to its lack of carbon. It's main drawback was that due to its softness structural/functional elements often needed to be thicker/larger to prevent bending. On the bright side, due to how easily wrought iron moved under the hammer, using it would give the appearance that your strength was due to being born on the planet Kripton. -

I use Gojo Hand Cleaner and a nailbrush. Works great.

-

Early American Wrought Iron: 3 Books in One Hardcover – May 3, 2006 By Albert H. Sonn (Author, Illustrator) https://www.amazon.com/Early-American-Wrought-Iron-Books/dp/0970766467/ref=sr_1_2?ie=UTF8&qid=1473821888&sr=8-2&keywords=early+american+wrought+iron

-

Pre 1840 mountain man demo

David Einhorn replied to D.C.'s topic in Blacksmithing, General Discussion

-

Pre 1840 mountain man demo

David Einhorn replied to D.C.'s topic in Blacksmithing, General Discussion

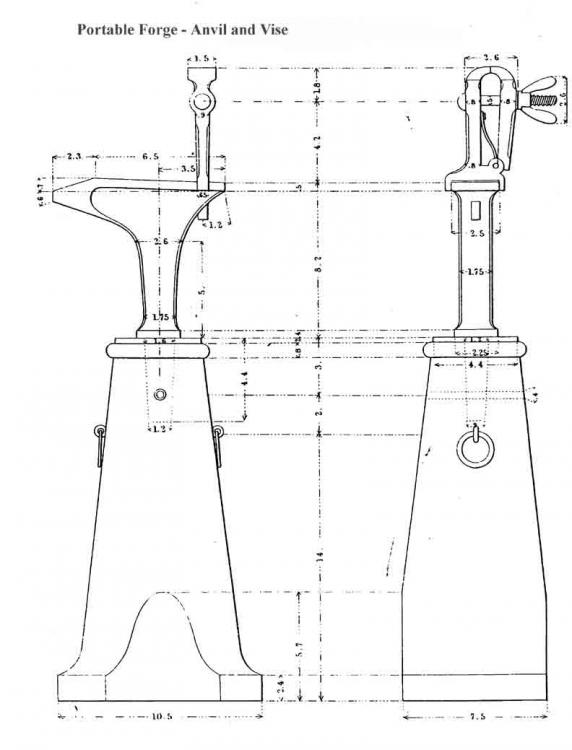

1840 is close to 1850s, so documentation on what was used for backpacking in during the 1850s are likely to apply to the 1840s. Hand vise yes. Here is a small-stump-anvil and hardy-mounted-vise documented in the 1850s by and for use of the U.S. Army. Leg vises were not carried on horse back and not mounted on wagons,,, for wagon mounted vise see wagon/tongue vise. -

I would have thought that blacksmithing, as an activity in Connecticut, would have become fairly widespread in the time since the introductory course I took about 43 years ago in Storrs Connecticut. That didn't happen?

-

Blacksmithing has come a long way since its resurgence in the 1970s. Back then if a smith could forge weld two pieces of mild steel together, he/she was held in an overwhelming feeling of reverence/admiration. And even in the early 1990s, I was in a course on forge-welding that, looking back, the instructor provided inaccurate information. By the end of the 1990s, Bill Moran who led the way for pattern-welding resulted in a surge in the number of people doing pattern-welding. Perhaps the increased number of people doing and experimenting had a hand in the increased/better understanding and knowledge of forge/pattern welding, and also possibly thus resulting in better informed authors. Politeness on the forum is a good thing. Too often I have observed experienced and highly skilled smiths become reluctant to share information due to rudeness and/or verbal attacks. Steve S is a nice person and knowledgeable about blade smithing. I look forward to his sharing his knowledge.

-

Side-blast forges used by the U.S. Army and Navy during the U.S. War Between the States did not use chimneys. My side-blast Naval and Army mid-1800s forges don't have chimneys and work fine that way. These are three mid-1800s side blast portable forges.

- 58 replies

-

- side blast

- super sucker

-

(and 2 more)

Tagged with:

-

Vinegar to remove Galvanized coating.

David Einhorn replied to LouieIV's topic in Zinc, galvanized, and coatings

I buy unplated "plain finish" fasteners and threaded rod at the local Fastenal stores. There are four of them within driving distance. They also will ship from their web site to your shop or home if that is preferred. I tried the route of removing plating with vinegar once and decided it was not worth the time and effort. They are manufacturers of fasteners, so if you set up a in-store account they will likely give you the wholesale discount. -

I recommend checking local community colleges to find out if they offer non-credit courses on building construction. Catonsville Community College in Maryland, for example, used to offer a set of courses covering: framing, foundations, roofing, welding, cabinet making, and building code. I found the courses to be very useful. After taking the courses, I was able to frame and raise sixteen foot long wall sections, twelve foot high ...... two wall sections a day, single handed without anybody's assistance.

-

London pattern design evolution?

David Einhorn replied to JHCC's topic in Anvils, Swage Blocks, and Mandrels

The book titled: “Anvils in America” by Richard Postman Discusses that at length. http://www.amazon.com/Anvils-America-Richard-A-Postman/dp/0966325605 -

I usually go to Boulevard Sales , about half the price of buying from welding/fabrication shops because they are one of those places that the welding shops purchase their steel. It's close to you and they will cut for a fee. Boulevard Sales Corp Structural Steel Supplier 7205 Washington Blvd Elkridge, MD 21075 410-796-9370 M-F 7:30 – 4 Sat 7:30 - noon

-

Most places have laws against blades more than a certain length, method of opening the knife, and/or with more than one sharpened edge. In some U.S. states, you could be legally carrying a particular blade in one town, then illegally carrying that same blade when passing through the next town. As to the when and why various laws were enacted, that would likely easily slide into the forbidden area of politics.

-

Replacing the airbags in the center of steering wheels, with sharp metal spikes would greatly improve people's driving habits. .... The more protected people are, the more they will push the limits.

-

If you add a handle on the washer/ferrel, that looks like you could make the opening adjustable if you wanted to. However, with a foot operated vise, I doubt if that would be necessary, since your foot is what is opening and closing the vise.

-

round or flat hammer face to hit punches?

David Einhorn replied to Ethan the blacksmith's topic in Hand Hammers

My forging hammers are for forging. I use brass, wooden mallets, and fleamarket ball-peens for misc. cold hitting of stuff. A friend used a brand new yet unused Hofi hammer (acquired through IFI) to bang on a guillotine tool before I could stop him, and I almost had a heart attack. Fortunately, the hammer appears to not be damaged.