-

Posts

2,617 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

: Near Gettysburg, PA

-

Interests

historical and general blacksmithing, researching blacksmithing ......... Retired.... No longer a Licensed Clinical Social Worker (LCSW) but I can't change that area of the profile page.

Converted

-

Location

Near Gettysburg PA, Baltimore MD, and York PA, USA

-

Biography

Hobbiest smith for over 35 years. I like to combine wood and iron in projects: tools, chests,wheels

-

Interests

Building a Civil War Traveling Forge. Constructing items of both wood and iron.Historical metal work

-

Occupation

Liscensed Clinical Social Worker, MA, MSW, LCSW, was a Software Engineer for 19 years

Recent Profile Visitors

19,744 profile views

-

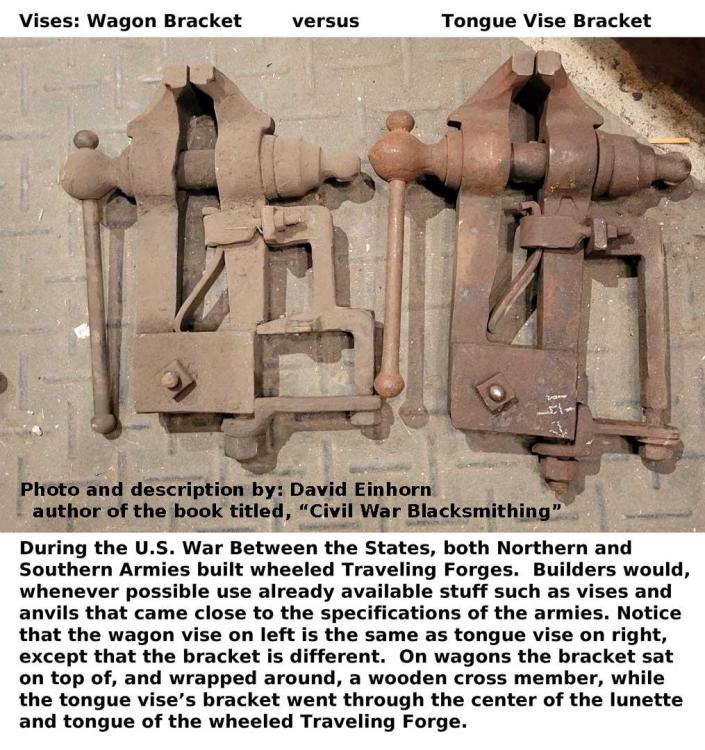

Good question. My humble understanding is that vise was originally and mainly made for settler's wagons traveling from the east (Pennsylvania mainly) westwards. If there was a demand for settler's wagons going west, then there would have been a similar market for repair vises to be mounted on them. If not, well... they were not ideal for other uses compared to dedicated bench vises, and blacksmith style leg vises...... That said, your vise is "Civil War" vintage, as identified by it's bracket.

-

I sometimes check this forum for postings with the words, "Civil War". These vises were mostly intended for use by smiths/farriers that made and repaired smallish items such as horseshoes. That is compared with leg vises that some folks include in the category of "anvils" because their leg rests on the floor, thus decreasing the chance of damage due to heavier pounding on what the vise is holding.

-

What is a good heat reflect dent to coat fire bricks?

David Einhorn replied to Fly's topic in Solid Fuel Forges

Last I checked there was a company in Maryland that sold refractory bricks to people with furnaces, especially artists. According to them the same bricks used in commercial blast furnaces. You might wish to look for a company near you that supplies bricks and/or refractory cement to artists. -

MickKrug started following David Einhorn

-

Accompanied an acquaintance into a shop in Gettysburg that was/is supposed to be reputable when it comes to Civil War relics, years ago. 1. He pointed out artillery items that were fake and described why. 2) A No.1 field artillery wheel was there for sale, and it was about 50% wood putty and parts that I recognized from a wheelwright shop in Lancaster, and included 3/8" buggy bolts where 1/2" tire bolts were supposed to be. And prior to that, I had attended an Early American Ironwork conference in Delaware where a smith showed me 1. that about half of the "Colonial" ironwork on display was reproductions and why. 2. Showed me items behind his truck seat that were on their way to supply relic stores in Gettysburg that he made. A few years ago, a leatherworker told me that saw one of the belts that he made for sale at a Civil War relic table at the convention center in Gettysburg. He showed the seller why it was identifiable as his, and the seller didn't care. The bottom line is to suspect the authenticity of ANYTHING that claims to be from the U.S. War Between the States.

-

Many years ago, when I took a course on welding at Fort Meade, the retired Colonel teaching the course said that he had permission to borrow stuff from the dumpsters for the class to weld on, that had to be returned to the dumpster(s) when finished with them.. He said he found whole offices worth of brand new furniture and new computers that were discarded because a new bigwig came in and wanted different stuff.... and that is was illegal to take any of it out of the dumpsters.

-

When they took down the in-laws family barn in Maryland, they found an early 1800s anvil buried in the foundation. No one in the family knew if it being buried was due to hiding it during the War Between the States.

-

-

I tried sending you an email with information, but the email address you provided does not seem to work.

-

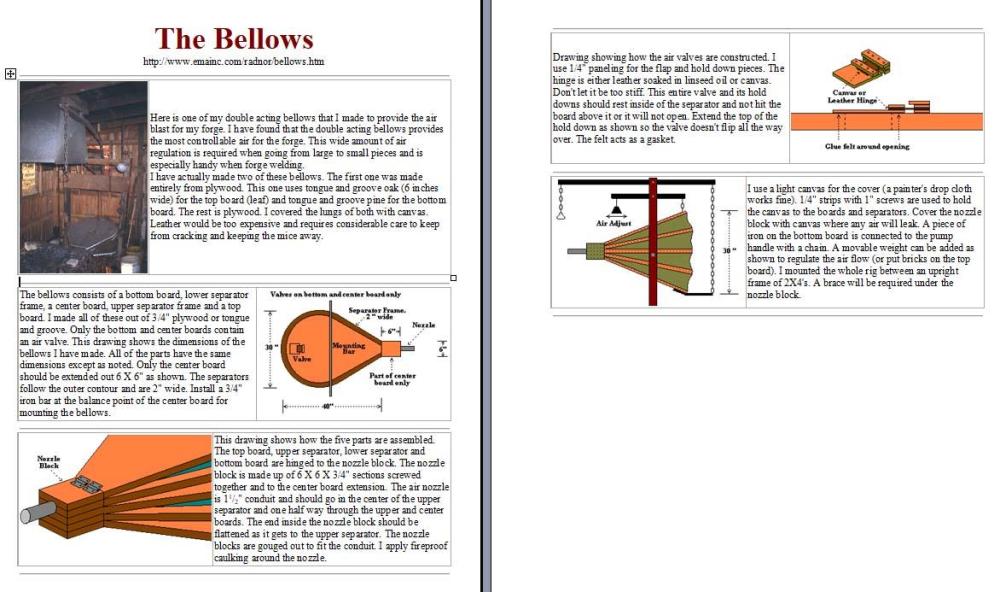

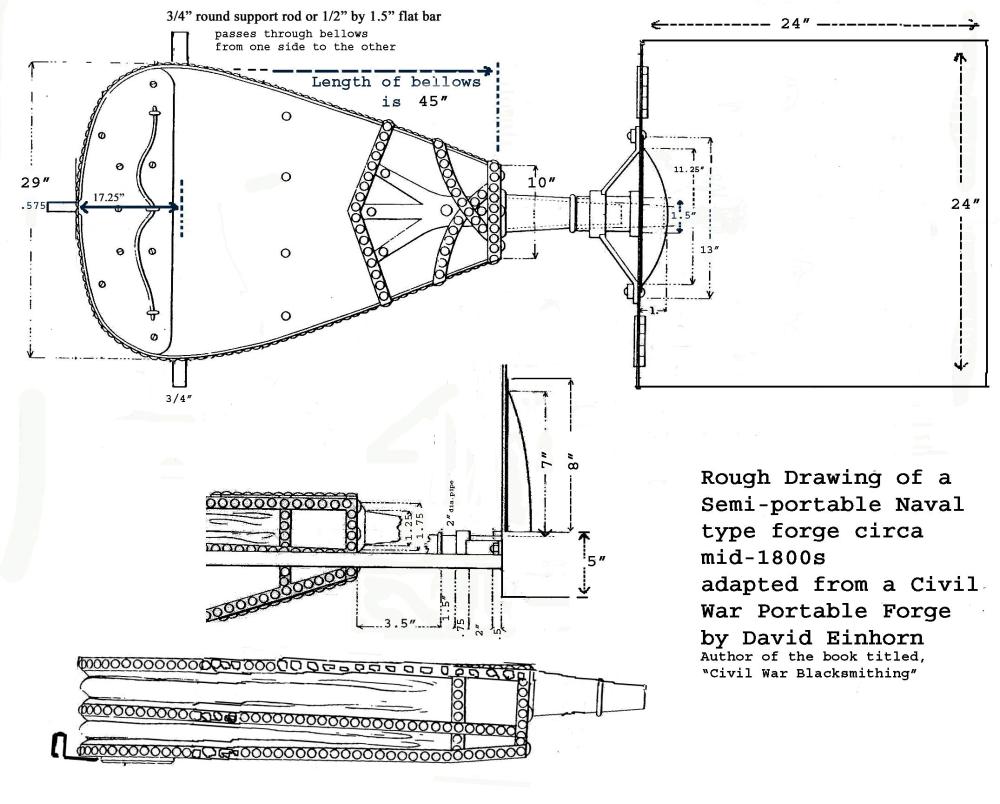

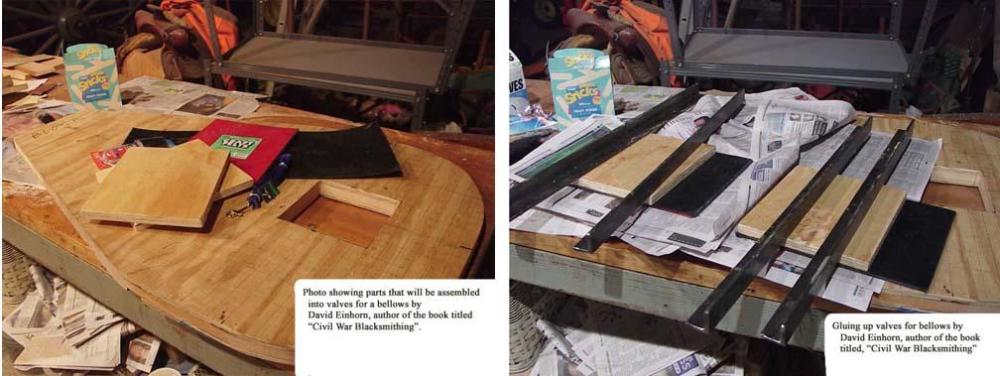

Most likely the appropriate bellows would be a two chambered bellows for reenacting living history for U.S. history. That said, different designs in Europe and elsewhere in the world depending on the time period of the living history event. Here is a mid-1800s U.S. Army diagram that I modified to try to recreate a mid-1800s naval forge. It is a two chambered forge, both the top and bottom boards are hinged. .... Again, bellows during U.S. history varied in size, larger in shops, smaller in military use, but mostly the same type (except for wheeled "Traveling Forges" which were very different.

-

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

Forge B - Park Service served mostly cavalry and infantry horses and mules and carriages. Pretty much anybody with a horse or mule that needed shoes. The tools and the accompanying Battery Wagon that accompanied Forge B, was set up for more general use and didn't have the same stuff as the supplies for the Forge A. (see the appendix in my book, or one of the Ordnance Manuals). Remember a Battery Wagon accompanied, and belonged to the smiths at, each and every Traveling Forge, and was outfitted with tools and spare parts for the role that it played,,,, see any edition of the "Ordnance Manual for use of....". -

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

>>>I’m going to purchase your book and Karl Orndorff’s, Blacksmith’s Traveling Forge .... Karl is a nice guy, but the only information that is accurate in his book is the information that his niece harvested from information that I posted to the Internet. Just about everything else he says in his book is nonsense. For example, he says that tow trucks and military ships are Traveling Forges. I extremely regret helping him with publishing his book. He is spreading false history. >>> ...... used a limber for all the tools the blacksmith/farrier would carry in conjunction >>>the traveling forge? Is this mostly the case? Each Traveling Forge was accompanied by a "Battery Wagon" containing tools,, Ordnance Manual or the Appendix of my book. >>>>“Were all the blacksmiths for the Armies in the civil war, enlisted? Yes all were enlisted and paid at the same rate as a corporal. Karl made up civilian blacksmiths to justify his building a monstrosity of a "civilian traveling forge" >>> If so, did they mostly wear uniforms/hats with their forging aprons? >>>>Or wear traditional blacksmith/farrier clothing of the time period? the period photos tend to show them mostly bareheaded, one shows an ethnic hat that no one that I have asked can identify. They wore either French cut shirts, or older work shirts. French cut shirts were too confining for someone working.. See photos by googling Civil war Blacksmiths or photo in my book. -

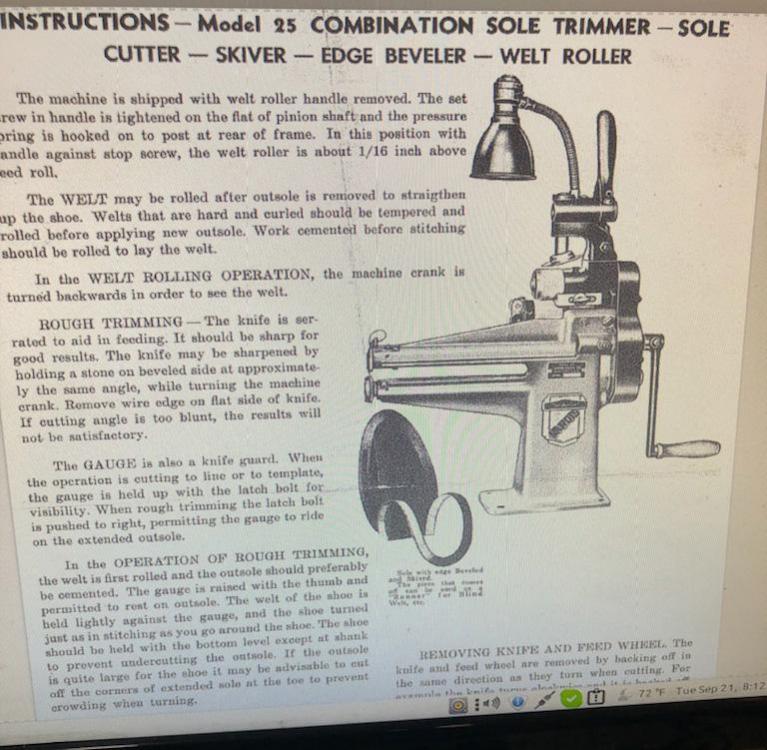

Champion Model H leather cutter.

David Einhorn replied to Anthony San Miguel's topic in Everything Else

It is a Champion model h - 5 in 1 Leather machine, similar to the Landis 5-in-1 machine. It cuts, skives, presses the edges of shoes for soles that are glued with contact cement, welt roller, and bevels edges. . landis_25_manual.pdf -

I gave up trying to establish a blacksmithing school there. I was well on my way to acquiring/building the equipment for six forge stations, and the Steam show association was planning on building a school building, with plans with the Steam association on expanding the school and building to twelve teaching stations once classes showed success.... but two members of the ABANA board decided to take over and tell me what to spend MY MONEY AND TIME on for equipment and workstations, and told members not to pay any attention to any news/progress I was providing. And the one board member pushed people away from the forge, and one other member spent his time repairing all the equipment that the board member damaged each time the board member used the forge. It got to the point that I was spending most of my time just trying to deal with those two ABANA board members interference and being called names for not submitting to them, rather than spending time acquiring, building and reconditioning equipment for the school. Last I heard, two of the anvils that I purchased were still held by one of the ex-ABANA board members, rather than being returned to the Steam Show Association's blacksmith shop.

-

Civil War era blacksmith wagon

David Einhorn replied to Glenn's topic in Blacksmithing, General Discussion

All Civil War military movable forges, and I mean all, were side blast forges.