-

Posts

2,617 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by David Einhorn

-

BGCM Open forge Oct 8, 2015

David Einhorn replied to Glenn's topic in Blacksmith Guild of Central Maryland

Next Open Forge is Oct. 8th 2015 from 6pm till 9pm Meeting for October is on October 25th, 2015 November's Open Forge night is November 12, 2015 from 6pm till 9pm Remember: You must become a member of BGCM and sign the release form to enter the forge area of the blacksmith school and to use the equipment there during Open Forge times and Membership Meeting times. -

If I am not mistaken the Anvilman and others responded to your same questions back in 2013 here is the thread referred to : http://www.iforgeiron.com/topic/35372-what-year

-

BGCM Open forge Oct 8, 2015

David Einhorn replied to Glenn's topic in Blacksmith Guild of Central Maryland

Due to liability issues, to enter the Blacksmithing School's forge area, a person needs to be a member of the guild by signing the release form and paying the club's dues. Open Forge: Thursday Sep 10th, 2015 Next BGCM Meeting: Sunday Sep 27th, 2015 Blacksmith Guild of Central Maryland http://www.bgcmonline.org/ Located at the Carroll County Farm Museum 500 S Center St, Westminster, MD 21157 (410) 386-3880 I highly recommend taking a course or two at the Blacksmith Guild of Central Maryland, you can find further information about beginner and intermediate courses on their website. New Classes: Call 410-386-3882 or Email register@bgcmonline.org BS-101: Beginner Blacksmithing October 3 - 4, 2015 (Full) BS-101 Wednesday Evenings Beginner October 7 - November 4, 2015 (1 Opening) Principio Hammer Making Classes with Nathan Robertson October 22 & 23 http://www.bgcmonline.org/index.php?principio (a few openings left) Principio Hammer-In October 24th http://www.bgcmonline.org/index.php?principio Admission fee is donation of hand forged item to the iron-in-the-hat raffle. Forge Welding November 7 - 8, 2015 (6 Openings) BS-101: Beginner Blacksmithing December 5 - 6, 2015 (Full) -

-

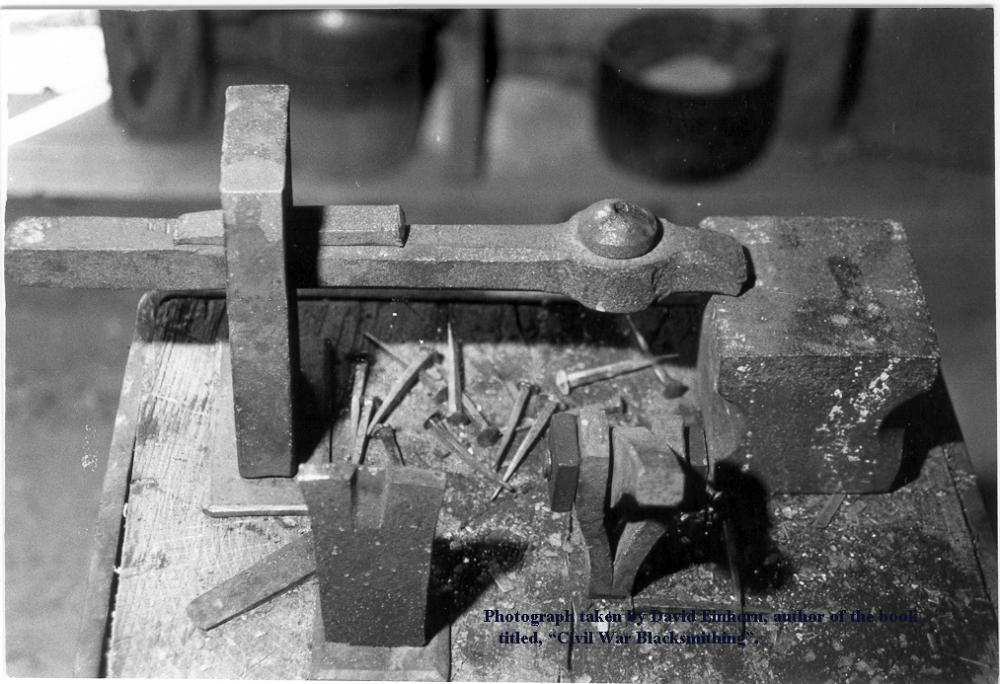

Years ago I visited the Williamsburg Blacksmith shop with the Mid-Atlantic Blacksmith Guild. They had a nail-making station that they constructed based upon their research. They needed the nail-making station because of the large volume of nails that they needed to manufacture. The top photo of their nail-making station that I took, the second photo is a Swedish nail-making station. The Williamsburg station is amazing, the taper is forged on the anvil block, then notched in the hardy, the hardy has flats on it to act as a stop, then broken off in the header, headed, and then flipped out by poking the lever that is next to the hardy.... all in one heat.

-

Iron has the tendency when hit to spring partway back. Some anvils are deliberately made with a tiny bit of sway so as, and with the intent, to allow for that spring back of the iron during straightening. Basically, by hitting the metal slightly into that sway with practice, it will spring back to straight rather than spring back to still being slightly bent as it would if the anvil's face was dead flat. In my humble opinion, that anvil is in absolutely excellent condition, thus giving evidence of the skill and knowledge of the smiths who have used it before you.

-

Super-sucker Sidedraft Sideblast

David Einhorn replied to j.w.s.'s topic in Chimneys, Hoods, and Stacks

Hopefully those more expert will chime in, but you might wish to try a larger diameter flue pipe. -

- 35 replies

-

- coal forge

- folding

-

(and 1 more)

Tagged with:

-

Super-sucker Sidedraft Sideblast

David Einhorn replied to j.w.s.'s topic in Chimneys, Hoods, and Stacks

What is the inside diameter of your flue pipe, and how far does it extend above the highest point of your roof? -

Have you tried a pipe wrench?

-

Many years ago when I lived in Baltimore, I disguised by coal forge so I could leave it outside. I made a removable table top out of 2 by 4s, and painted it with a redwood colored stain. The top hung over the edges of the forge. No one bothered with what looked like a really cheap and ugly fake redwood table. If it were me, I would make an inexpensive forge table with removable firepot and blower, and a removable fake redwood table top. I would use 2 x 4s for legs (stained like the top), and an piece of an old washing machine or dryer shell as the top, with a hole for the removable firepot. That way it is not very desirable to steal, and even if they did steal it, would be cheap to replace it. Personally, I would try that before trying to deal with something that I had to move up and down stairs. But that is my preference, and may not appeal to other folks.

- 35 replies

-

- coal forge

- folding

-

(and 1 more)

Tagged with:

-

Patrick, Excellent! I will be the one wearing a name tag with my name on it. I tend to arrive a bit late to the meetings. Dave E.

- 3 replies

-

- new

- blacksmithing

-

(and 1 more)

Tagged with:

-

I was going to suggest going to a Blacksmith Guild of Central Maryland [BGCM] meeting, but this month's meeting was today. The next meeting is Sept 27th, starting around 9am. At a meeting, if you join the guild, you can then ask most of the experienced folks to help you at one of the forges at the blacksmithing school, to get started. Us old farts are happy to help. You can also purchase bags of coal at guild meetings after you join,.... at the membership discount price. As an added incentive Patrick K. if you come to the BGCM meeting and join the guild by filling out the membership form and paying your dues, on September 27th, 2015,... I will gift you a signed copy of my book. If you join that day and I am not there, then Private Message [PM] me that you were there, and paid your membership dues, and I will mail you a signed/gift copy of my book. http://www.bgcmonline.org/index.php?calendar&year=2015#123 Best wishes, Dave Einhorn

- 3 replies

-

- new

- blacksmithing

-

(and 1 more)

Tagged with:

-

Clamp on bench vise....

-

Quick and Dirty Forging press's comming soon.

David Einhorn replied to monstermetal's topic in Presses

I would really like to have a great forging hydraulic press. Unfortunately being short of money, I tend to build what I can afford with parts that I can afford. -

What oil should I use for quenching?

David Einhorn replied to Forging Carver's topic in Heat Treating, general discussion

There is no need to quench the nail before putting it into the header, or after when it is finished. .... That said, if you feel the absolute compulsion to quench any part of a nail, water should be fine for low carbon iron. -

Welcome from York County Pennsylvania. Depending on how far you wish to drive, some guilds that may be within driving distance include: - Blacksmith Guild of Central Maryland http://www.bgcmonline.org/ I highly recommend taking a course or two at the Blacksmith Guild of Central Maryland, you can find further information about beginner and intermediate courses on their website. - Pennsylvania Artist Blacksmith Guild: http://www.pabasite.org/ - Philadelphia Blacksmiths Guild https://sites.google.com/site/stuarttheblacksmith/home/hammertymephilly-the-philadelpia-blacksmiths-guild - New Jersey Blacksmith Association: http://njba.abana-chapter.com/ - Central Virginia Blacksmith Guild http://cvbg.org/ - Blacksmith Guild of the Potomac http://www.bgop.org/ - Mid-Atlantic Smiths Association http://masametalsmiths.org/ - Tidewater Blacksmith Guild http://tidewaterblac....com/index.html - Chesapeake Forge Guild meets at the Kinder Farm Park in Millersville http://www.chesapeakeforge.org/ - For a more complete list visit: http://www.abana-chapter.com/

-

Bearing or any other grease should do fine. I have used whatever is on hand.

-

Steel from a supplier

David Einhorn replied to Michael Cochran's topic in Blacksmithing, General Discussion

Apparently our local steel yard does things differently. Drops are full-price and sold per foot, so I have given up on buying their drops. If you don't pay for a cut, you won't get anything cut. For a while they were charging $2 per cut, so if they cut 20 quarter-inch rods in one pass of the chop saw, that one swipe cost you $40. The guys in the yard have a pretty big turnover in personnel, only one gentleman is still there the 30 or so years that I have purchased from there. ... Still, it is much cheaper than the big-box stores. .... My point is never assume that someone's experience at one steel yard will be the same as the steel yard near you. -

Hungrian pre WWII Cast Steel Austrian Style

David Einhorn replied to Ivan85's topic in Anvils, Swage Blocks, and Mandrels

I fully agree and expect that the group is likely to also agree with Frosty. You are more likely to ruin the anvil by trying to modify it. Use it as is. -

Toasters are traditional. Lots of designs available if you Google on "wrought iron toaster" , then click on "images"

-

Sprinkle a couple of drops of water on the anvil, then hit the drops with hot iron. The water turns instantly to steam, displacing air. Bang!

-