-

Posts

2,335 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by John McPherson

-

Blacksmithing gems and pearls

John McPherson replied to Glenn's topic in Blacksmithing, General Discussion

Glenn, I once had to research the width of the tire spacing on a Model T in order to estimate the dimensions of a long gone historical smithy from the one photograph of the building. It just happened to be in the background, and was not the subject. (I mean, really, who documents old buildings? Why would anyone want to know how big a barn or shed is, when we have this beautiful antebellum mansion? Weirdos!) -

Grape clusters, molecules, solar systems, and, oh yeah, darn good knives.

-

Can't get links to work, but if you search for "Cambria blacksmith shop" several sites will show up with more historical background and interior views. The NoDa section of Charlotte was a depressed area of town before it became an artist colony, now it is trendy and expensive. Asheville NC was a dump 40 years ago when industry left, art keeps it alive. It might work for them as well.

-

What Thomas said: get thee to a place that sells and services heavy trucks and Ag equipment. I know that Nebraska has big green tractors galore. Ask for bent/replaced shafts, axles and track pins.

-

Worst I have seen

John McPherson replied to Reeltree's topic in Repairing and Modification to Anvils

I like to use cars as an analogy, or food. Folks can relate to those better. Which is better, and will hold its value to pass down to your kids? A 10 year old Mercedes with 100K miles, or a budget Asian or East European import, same year, same miles. Or a fast food meal in a paper sack, vs a sit-down, knife and fork meal in a nice restaurant. Both will fill your belly for a few hours, but one is a poor choice for Mother's Day, unless you WANT to be left out of the will. Which brings me to a question. If we in the States go to Outback Steakhouse, do you Aussies go to an American themed joint? I can see it now, Vinnies New Jersey Chophouse, "Fuggitaboutit". Inquiring minds want to know! -

One of 200+ short-lived manufacturers of English anvils. Some lasted a few months, some a few years, only a few lasted for decades. Much like any industry, there is a shake-out phase, and just because you learned how to make a product while working for someone else, it does not mean you know how to market it, or have the capitol reserves to withstand a setback.

-

Hey, when I get out of one of my vehicles, the spot value halves. I can carry the same wad of bills around for months, but when a windfall lands in front of me, BAM!

-

We have not had a similar discussion in my household since she bought her THIRD (!) programmable sewing machine. Which cost more than any vehicle that I have bought in this century, BTW. There is a (formerly) walk-in closet in her sewing room that is packed solid in cardboard office paper boxes and plastic bins of fabric 'stash'. The overflow is in drifts around her sewing table and ironing board, the only visible flat surfaces. There was no discussion when I purchased two high cube storage trailers for our stuff at the farm. Not since the the local crackheads had stolen our golf cart, welder and weedeaters, among other things. And as for walking around money for impulse tool purchases unexpected bargains, I feel naked with less than $500 on my hip at all times, and $5000 reserve in the farm savings account for the big stuff. I am willing to make trade-offs in other areas to afford my 'stuff'.

-

Long ago, someone shared a picture of warming up the blower grease at -50F. Do what ya gotta do. Bruce Wilcock was in the north of Scotland: on a busy day, the 5 CWT anvil got hot enough from use to set a kettle on and have a "boil-up" at lunch. That is pure hustle from a 60+ year old man! No anvil perching during breaks.

-

I believe it was Mark Twain that said "A lie can travel halfway around the world before the truth can get it shoes on." As I get older, I agree with him more.

-

Looking at some anvils today

John McPherson replied to Medic Zack's topic in Anvils, Swage Blocks, and Mandrels

Hi, MZ. Welcome to the insanity of recent anvil prices wonderful world of lemming driven market forces in capitalism. There are a couple of guys that buy up and then resell anvils and vises on CL, including one IFI member in Denver, NC, just west of Lake Norman. You will get no crazy sweetheart deals from them. The very best you can hope for is current market value, "fair" or not. Read up on TPAAAT on this site, and look for folks NOT interested in selling anvils, until you ask them, that is. I have driven from Charlotte to the VA state line to buy a $250 200lb colonial anvil for a museum from someone who did not know what he had, and posted a cruddy lo-resolution picture on CL. The deals are still out there, just harder to find. And you know, of course, that there is an active NC-ABANA sub-group just down the road from you that meets regularly at the Dixie Classic Fairgrounds? Where you could get expert guidance from local smiths, and maybe pick up some items at a tailgate sale. But who would want to do that? -

There are no universal tongs. Except for the late Grant Sarver's Off Center Products Universal Tongs, that is. Don't know if anybody still carries them. I love mine. Of course, universal wolf jaws would be the next closest thing. If I can only take a few items to a demo, those are my two favorites, and will handle 99% of what I do.

-

Not to get long-winded (too late), but yes to all of the above. Yes, really working the teeth in, as opposed to grinding the tops off and leaving the dimples (see stolen image #1), weaken the blade. I would suggest a progressive grind from the edge to the spine before forging out the edge. But it is just an herb chopper. (Is there a market for Tactical or Zombie Apocalypse herb choppers?) You do not tend to rely on it and abuse it like a Bowie knife carried in the belt whilst hunting grizzly bears with a singe shot black powder rifle. An edge quench in hot oil, leaving the body and tang soft is generally advised for blades made from high carbon steels like files and rasps, plus the hamon is considered aesthetic. Draw the temper in an oven starting at 350F for an hour, then 400F, 450F, etc., until a new file does not skate on the edge, so that it can be easily sharpened. If you still worry about it being tempered too hard, throw it on the concrete a few times. If it does not shatter: success!

-

I know your pain. I had to fix a handrail for a museum yesterday just as the school was closing. Running around to find (1) (a) a welder with tips AND wire (1)(b) a working welder with tips and the right wire, but so little left i could see the core of the spool (2)(a) a tank of mix gas that was NOT empty and unmarked (%&$# lazy students) (2)(b) the tools to fix the leaking gas line on the working welder with tips and the right wire (double %&$#), change out bottles, regulators, etc., all in order to (3) run a grand total of 4 inches of bead on the brackets I fabbed up. I finished up with just a few wraps of wire left on the spool, and the brand new Security officer trying to lock me in the courtyard, having already locked all the exterior doors so that I could not re-enter the building. And my wife is mad because I am not answering my phone during all this, I am late for dinner, and my installing this Saturday morning interferes with her plans for me. They say that no good deed goes unpunished, but at this rate waterboarding is next.

-

If you take the time to haunt museums and collections the way many of the professional smiths who make high end reproductions do, you will be struck by how Light and Thin daily use weapons were historically. Also, how roughly made many items were when you get up close. Fit and finish on ricassos and tang transitions, hilts and guards tended to be especially sketchy, but the blades were always smooth. This holds true from the Roman gladius right up to the Dragoon saber. All of which is 180 degrees out of sync with modern sensibilities. Because many of our blades are not daily users, they are status symbols, or outright fantasy. Much like the court swords of nobility in the past. If you don't believe me, take a look at any bladesmith's website who carries a line of 'field grade' or plain hunters vs Gentlemen's knives, or kitchen vs zombie choppers.

-

Owen, platen tables run from scrap price per pound, up to $10K, depending on the usual factors: advertising - or the lack thereof, location, accessories, condition, supply, vs demand, and just how the heck are you going to move a couple of tons of iron? A 5 X 10 weighs more than a Chevy Suburban. Tractor forks would not touch it, you need a BIG industrial forklift. Ten years ago when the economy tanked and machine shops were being auctioned every week, I saw them stacked like pancakes in the scrap yards.

-

Owen, Acorn and Weldsale are brands of platen tables, the big cast iron plates with a grid of square holes for fixtures. They have been around for more than a century, and are still a great tool to have available for any sort of large fabrication project.Whether you arc weld items on top of it, (student project below) use it for straightening, riveted or collared blacksmith projects, etc. Also see beaudry's layout table pictures in the shop section.

-

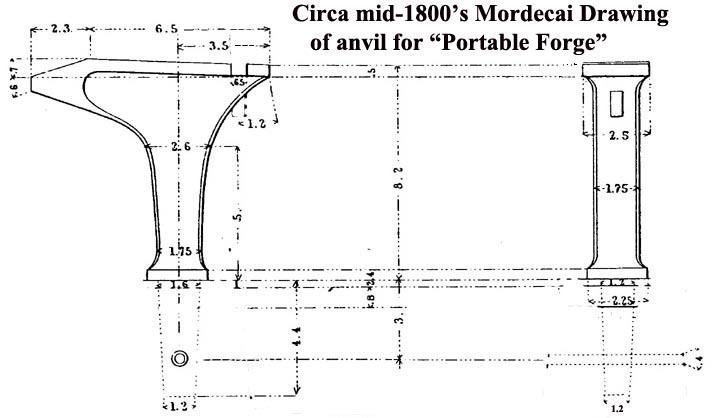

ThomasP, you lucky dog (or werebear, IDK), that is a military wagon or pack mule anvil. Worth serious $$$ to a collector.

-

How to make a perfect forge weld, every time.

John McPherson replied to Glenn's topic in Blacksmithing, General Discussion

Somewhat paintball related? Where does one get a nuclear reactor from a Russian sub to power your coffee-maker anyway? -

Welders start fires all the time, at least according to the news. A homeless person died this weekend from a warming fire in a crawl space in an abandoned building. I work hard at keeping new students safe from themselves in the shop, until they know better. Some are harder to reach and train than others, and there is a lot of backsliding on the part of the inherently slack. And sometimes, there exists the perfect storm of ignorance, arrogance, stupidity/brain damage/chemical enhancement and the Y chromosome. Which all adds up to an area effect weapon, which can not be legislated out of existence.

-

Bright lighting tends to wash out the colors. Every try to read a phone screen in full sunlight? When you get an eye exam, is the office lit up like a tanning booth, or dim and subdued? Are you forging in open air and bright daylight, or under bright artificial lights? A metal bucket on it's side, painted inside with flat black paint, may help in that case. Traditional bladesmiths did their heat treatment after dark, or with the shutters drawn during the day, to better distinguish colors.

-

Punch and Chisel Storage

John McPherson replied to Brandr Forge's topic in Slitters, Punches, Drifts, etc

-

Forty plus years a Scoutmaster, and 10 as a Professor of Welding Technology, and yeah, I can size someone up to those standards fairly quickly. It is literally my job to evaluate shortcomings and educate on how to surpass them. I rarely get surprised, and much more rarely is it a pleasant surprise. Some folks get good at hiding their flaws in front of strangers, at least at first. I have a personal theory, based on observations, that folks get into things at the same speed that they get out: hobbies, jobs, careers, vehicles, even relationships. Some folks are mercurial by nature, others plod and analyze every facet. Technological crutches don't help the understanding that only comes with experience AND reflection.

-

Identify me, please!

John McPherson replied to Cavpilot2k's topic in Anvils, Swage Blocks, and Mandrels

Hay-Buddens were American and marked in pounds, yours is English. A little chalk on the markings wound help with ID. The keel shape under the horn, and the squiggle next to _ _ LE makes me think Mouse Hole Forge. If so, the SN fits with the shape between 1896 (SN 9106) and 1911 (SN 24342). Say around 1900. -

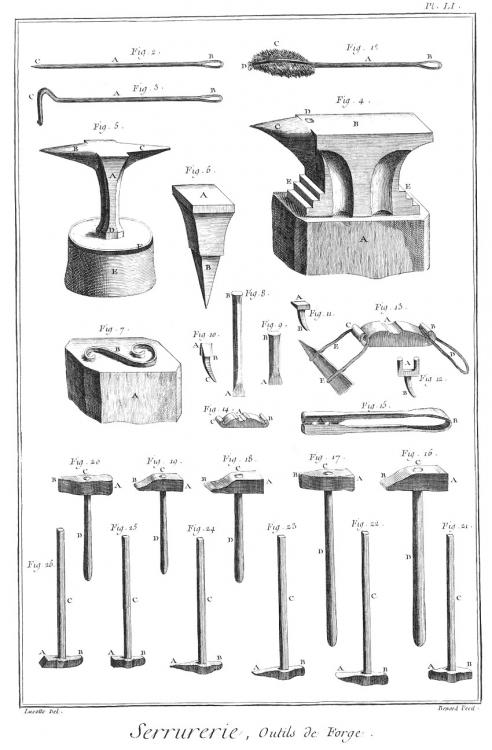

Blacksmiths have punched holes in steel for millennia. Hardy holes & pritchel holes in anvils, and cast iron swage blocks all appeared in the historical record in a fairly short time frame, about what we 'Muricans call the late Colonial Period. Prior to the Industrial Age, leg vises and a blocky anvil were about it in a basic shop almost anywhere, although anything was possible in an urban center. Diderot shows individual bottom tools that strapped across the top of the anvil, but no swage blocks as we know them. Punching was likewise done with a bolster plate over the edge of the anvil, or on a suitable support. Got a drill and some scrap plate, plus some spare time? Make one for round holes, and make or buy matching punches. When you get better, you can make square or any shape your heart desires.