-

Posts

2,335 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by John McPherson

-

The problems with downhill welding are (1) lack of penetration at the root of the weld from moving too quickly, and (2) not so much the size and liquidity of the puddle of molten metal, as it is the viscosity, of lack of it, in the slag. Some E6010 rods are made especially for downhill welding, and are a staple of cross county pipeline work. Solid wire MIG or TIG has no slag, only gas shielding. Heavy slag stick rods like E7018, or flux cored wire from a MIG unit, will almost always have slag inclusions trapped in the weld bead if run downhill. Not to say that it can't be done, but hard to do well. Not a beginner level skill. Smart companies go to great lengths to allow the shop welders to perform as much work as possible in the flat and horizontal positions. Chain falls, slings, trolley cranes, turntables and positioners are staples in any production shop. More and better work completed quickly, with less stress on the worker. You can't lay a bridge or a skyscraper on it's side, or put it on a rotisserie, so structural welds are vertical up and overhead by necessity and code. Use any means that works on your personal projects, but there are codes in place to promote public health and safety for valid reasons.

-

Safety gear in historical recreation setting

John McPherson replied to JHCC's topic in Safety discussions

Are we waxing poetic, or is that poetic wax? Or maybe wack poetry? -

Far from being an expert on the subject, to my jaundiced eye it looks like a Great Depression era product, or a lower tier offering from earlier times. In order to keep prices low, there was often a premier, tradesman and a homeowner line. Rougher finishes, less ornamentation, sloppier fit-up, etc. for a lower price. We still do it, Cadillac vs Chevy.

-

Safety gear in historical recreation setting

John McPherson replied to JHCC's topic in Safety discussions

The Colonial Williamsburg smiths do not ever seem to wear eye or ear protection. I, on the other hand, have had to have a specialist remove a sliver from a wood splitting maul from my eye on a weekend, many moons ago. Without insurance, it cost me enough to buy a lifetime supply of PPE. I don't even buy sunglasses now that are not safety rated. Yelp Rated -0- out of 10, would not do again! Not an experience to repeat in this lifetime. And that, boys and girls, is how Uncle John became a Safety Nazi. -

Can welding "un-anneal" steel?

John McPherson replied to lastcowboy32's topic in Welding/Fab General Discussion

The problem with dealing with unknown steels is all of the unknown variables introduced. It takes about 12% chromium to make steel stainless, but it makes it presence known above about 1%. If there is enough chromium content or other alloying elements in the metal to make it air hardening in thin sections (less than 1 inch or 25mm) then yes, just welding nearby without a preheat, and letting it cool will cause hardening. Large sections of cold metal nearby acting as a heat sink, application of water or just a breeze on a cold day will make it worse, as will thinner sections, like your 1/8" plate. The good news is that spot heating to bright red with a propane plumbers torch, and then slowing the cooling rate, can give you enough softening to drill or file, and make it less likely to break in the future. -

Show me your anvil stands

John McPherson replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

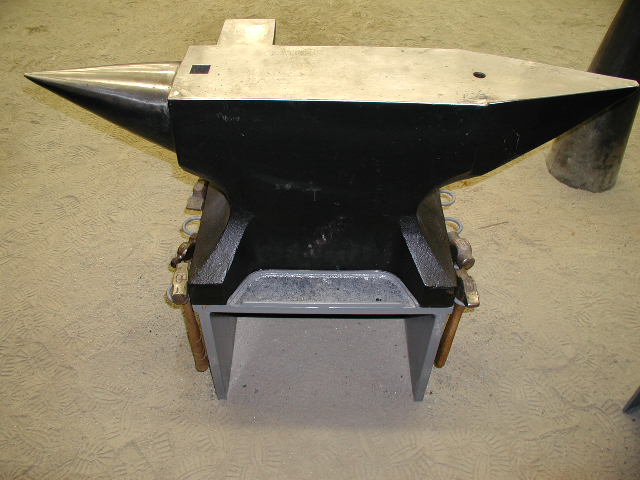

Since good pictures are worth many words, I attached a few from my archives. All are of big to HUGE anvils, solidly mounted. Suitable for teams of strikers with sledge hammers, or twisting big stock. The biggest Refflinghaus on an open box made from heavy plate by an expert fabricator. A concrete anvil column with rebar. A RR shop special, 701 lb Hay-Budden with matching cast iron stand. -

Well, around here the wind usually comes from the West. The 1815 house museum where I volunteer had me set up my portable demo outfit the first year on the west side of the event, under protest. Even with a small charcoal fire instead of mineral coal, I spread ashes, smoke, and discontent on the vendors and patrons at the main house and gardens. Ten years later, we have built the historic interpreter's smithy on the east side of the main house. Right about where the old smithy, barn, outhouse and sheep shed used to be, back when air conditioning meant opening the windows to catch a (hopefully non-odorous) breeze. Pretty smart, those old-timers. Particularly smart when you remember that they had particularly flammable cedar shake roofs.

-

Armitage Mouse Hole no pritchel hole

John McPherson replied to Daswulf's topic in Anvils, Swage Blocks, and Mandrels

The C & A mark would probably put it between 1795 and 1820 according to Postman. Then M & H Armitage Mouse Hole from about 1820 - 1835, and Henry Armitage Mouse Hole from about 1835 - 1854. -

Ray Clontz build - Lead weight needed

John McPherson replied to Stitch's topic in Power Hammers, Treadle Hammers, Olivers

Buckets of wheel weights are often free for the asking at any tire shop. Lead is a low temp metal, and melts in a stainless steel bowl or pot just fine. Heat source can be a wood camp fire or gas camp stove, a coal forge is overkill. A mold can be a cookie sheet or bread pan. The finished project can be trimmed and drilled with hand tools. That is how we made the counterweight on my friend's hammer. All kitchen stuff came from yard sales & thrift stores. Honestly, if you want to get into blacksmithing on the cheap, you are going to have to learn to scrounge, and try some new things. -

The IRS will not let you continue to claim a business that does not make a profit more than a certain percentage of years. That still does not negate the need for local and state business paperwork, yearly tax filings, record keeping, etc. My state says that if I charge one dollar for a service or a product, I am in business and need to jump thru the hoops, or else. YMMV. Consult a professional, such as an accountant or attorney in your state.

- 13 replies

-

People say that when I sing, my voice fills the hall. In fact, folks start getting up immediately to MAKE more room for it!

-

sand, a similar vise was posted on here a year or more ago, might want to look for that thread if there are any pictures still left. Frosty, my wife has figured out that I am not going to let another deal get away if I can help it. I have been skunked or sniped too many times. The ones that get away will haunt you. Out on a random trip. "Honey, I only have $7, how much cash do you have?" "I am a little short at the moment. Only about $700, mostly hundreds." "You @#%*" Ah, but the sweet satisfaction of picking up a primo tool and walking staggering out with it, and guys stopping me before I get to the car, trying to buy it. I have also had students tagging along at an event with a tailgate section, and will lend them cash on the spot. They have never failed to pay me back.

-

Yes, the ones on the right are farriers tongs. Frequently mistaken for button or bullet molds. Sturdy and compact jaw design means they that they can be used for hot or cold shaping without getting in the way of hammer or anvil.

-

Like anything else, it depends on the governing code. The AWS has NO pre-approved procedures for downhill welding, EXCEPT E6010 on pipe. But many large US companies have done the required engineering to write up and document their own proprietary weld procedures. All it takes is time and money, and somebody qualified to sign the document. What happens in the rest of the world, I can't swear to.

-

With that grainy texture and raised trademark, it is definitely cast, but from what? Something weldable and machinable. Castings became hard to make in the US due to OSHA and clean air laws, most production moved overseas years ago. If you have to have it made in the US, welding it up and machining it down is the way to go. It is a simple fabrication job, but you may not like the price for just a few.

-

I was taught never to bring up religion or politics in public, and good 'que is both in the Carolinas, ya hea'? But y'all started it. ThomasP, would that be 'Western NC' (Lexington) style chopped pork shoulder with tangy tomato/vinegar sauce, Eastern (Coastal Plains) style chopped whole hog with a spicy hot pepper/black pepper vinegar sauce, or SC style with a mustard based sauce? The appropriate sauced slaw on top if made into a sandwich, of course! After the new Interstate made it possible to bypass central Columbia, SC, my wife and I would still go miles out of our way to go by the original Maurice's Piggy Park to pick up a couple of pounds to go in the cooler, and some fresh fried squash, fried okra, and hush puppies with our sandwiches. Sadly, it is now but a shadow of its' former glory. (Clears throat.) And if it ain't pig, it ain't 'que. (Drops mic.)

-

Hay Budden Anvil Identification question

John McPherson replied to redstone71's topic in Anvil Reviews by brand

99.9% sure that you have a Hay-Budden, due to the "picture frame" on the base. Every one that I have ever been able to examine has that detail: thin raised rim around a recessed base. Makes it sit flat without rocking on most stumps or mounting stands. Oh, after about an hour only an administrator can alter a post, the edit feature times out to prevent meddling with content. -

What did you do in the shop today?

John McPherson replied to Mark Ling's topic in Blacksmithing, General Discussion

Michael Cochran: looks like someone re-purposed an axle or perhaps PTO spline into a digging bar to me. Which would make your hardy a third-hand use, or would that be second tier up-cycling? -

I can't say that I know a lot of independent HVAC contractors, electricians and plumbers, but most of the ones I do know have a specialty truck or van ($25-75K new) filled with specialty tools and parts ($10-25K) and a shop that they go home to every night where they keep extra gear($?) Add business licence, insurance, bookkeeping/office/phone/accountant and a field assistant, and the overhead is significant, before you make a dime. Are there some jacklegs getting by with less? A beat up domestic mini-van, some basic tools in drywall buckets and a cell phone? Going to the big box store for every bolt and washer? Do you trust that guy with your home or shop repair? Is he licenced and insured? How long has he been in the business? The same dichotomy exists in blacksmiths. There are ornamental and job shops in industrial parks working from CAD files and booked months in advance, and there are guys that dink around in a shed. Don't expect the same price or attitude from both. The problem is, the public that either can not or will not appreciate the difference. That lady is one of those.

-

Alan, I am just a dumb ol' welder (with a wall full of college degrees and certificates) so I am trying not to take too much umbrage with your implied put-down of other trades. Which is why I have not replied until now. There seems to be a world-wide trend of denigrating those who work with their hands. Are there some nit-wits in every field? Absolutely! The sheer number of patients who die by medical malfeasance dwarfs the number who die in traffic accidents in the US. Those MD's who are responsible are highly trained, highly paid, and high social status nit-wits and not unlettered tradesmen, but still nit-wits nonetheless. 50% of everyone in every field is below average. This is why we mandate licensing, certification, re-qualification at prescribed intervals, and other measures for everything that involves public health and safety from driving an automobile on up. There has to be some sort of floor below which we will not allow activity. Everyone seems to be acquainted with a least one lucky idiot (or conniving scoundrel) who always seems to stay one step ahead of disaster in their field.

-

is this chipping a real concern ?

John McPherson replied to JT's topic in Anvils, Swage Blocks, and Mandrels

It certainly would be to me, and I already own a 330 pound anvil in that Southern German pattern. This fat guy would trade up in a skinny minute. -

Rylan, he means fleaBay. Look it up yourself, no advertising links allowed.

-

I use it for convenience: it is stable for years at room temperatures, and transports well. I have no fixed shop, so everything has to go back in a job box at the end of each open air forging session. Or back in an SUV cargo area at the end of a demo. It resides happily in a thrift store find steam table tray that fits in a 5 gallon bucket with a lid. A yard sale cookie sheet will snuff out the flames if it gets heated to the flash point, and makes a handy drain tray for items as they cool. Is it the very best medium for all sorts of edged weapons? Probably not, or no one would go to the trouble of making vertical quench tanks full of Parks 50, or heated salt pots. If I was to go into business, my customers would expect nothing less than my best work at all stages of production. My conscience would allow nothing less. Adequate for blacksmith knives, punches, chisels and other small items? You betcha.

-

Small scale retort?

John McPherson replied to Exo313's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Absolutely scale-able! Scaled down: artists turn willow twigs into charcoal pencils, and primitive campers make char cloth in Altoids tins and shoe polish tins. Scaled up, somebody once posted on turning a burnt-out (vandalized) dumpster into a room sized retort. 55 gallon steel drums, old water heaters and heating oil tanks are soooo last century. Find a tanker truck! (And take pictures.) -

What is the most useful anvil weight and shape?

John McPherson replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

I have never been able to locate and try out another anvil that is the equal of my 150 kilogram Euroanvil Southern German pattern with the upsetting block and side shelf. That includes the student anvils at JC Campbell Folk school, and many other places. Still have not tried a big Refflinghaus, Nimba, Fontanini, or Papa Rhino, so the jury is still out. I will never trust another student on it, so it stays locked away and hidden most of the year. Sacrificial anvils are fine for those who hammer like lightning. (Uncontrollable, unpredictable, always damaging, and never in the same place twice!) While I can work solo just fine on a 100 pound London pattern, 200 pounds is better. Not 2X better, but noticeably different. But I would want a much bigger anvil if I had more than 2 minutes of team striking with sledges. Same thing applies to swage blocks. If you are hammering on a 90 pound swage with a 2 pound hammer on a light shape, fine. But you really NEED a big industrial block for big work.