-

Posts

1,075 -

Joined

-

Last visited

-

Greenbeast started following Joel OF

-

Thanks. This is more of a symbolic project than about making a strong useable chain.

-

Thanks Thomas. That style of chain was what I was thinking would be suited but I thought I'd seek a second opinion.

-

I'm looking to host an evening forge-in of sorts for a network of folks I've recently met, (non blacksmiths), more of a social event rather than a lesson, but I'd definitely still be watching over to guide. I think I could handle 6 folks at a time working in pairs so folks are helping each other out and not working alone. Each "forge=in" would probably last 3 hours, followed by a BBQ. My initial thought is I should get everyone making very slightly decorative chain links, (something just a little more interesting than a standard link, NOT forge welded), then as each working pair's pile grows, we start to link them up into a symbolic chain. The next class of 6 folks on another day can do the same and slowly the chain grows... Has anyone done any similar events? Has anyone got any picture references they think are relevant or got any other suggestions for items the groups could make? Cheers in advance.

-

Tooling direction... need advice.

Joel OF replied to Allen Corneau's topic in Tools, general discussion

A guillotine tool because it's the most versatile. By changing the dies you could butcher the shoulders with 1 set, draw the tenon out on another set, (or at the anvil), then round up the tenon on a final set. You'd still need a monkey tool though to dress the shoulders back, though. If your dies were wide enough & you had a specific size of tenon you were repeatedly making you could just use 1 set of dies for butchering the shoulders & rounding up the tenon by fabricating the dies to do both jobs. You'd need to draw the tenon out at the anvil though. -

Tooling direction... need advice.

Joel OF replied to Allen Corneau's topic in Tools, general discussion

You're always going to have to make tools and jigs to suit one off jobs, there's no way around that unless you only make a certain range of items. Although it's a slightly different answer to what you may have been hoping to hear and is possibly a little way down the road for you yet...fly presses are very versatile tools. You can in theory use them for riveting, making collars, punching, forging tenons... -

Elegant stuff. When the customer has finished their first bottle and reaches for the second when their hand eye co-ordination is a tad off, could they catch their hand on the sharp looking scroll ends?

-

Everyone seems to get a kick out of knots, no precise forging techniques needed, just bending some metal. This is a video I made a few years ago in my old workshop of making a knot from 6mm (1/4") round bar and attached is a picture of how I used to turn them into keyrings. Enjoyable for kids.

-

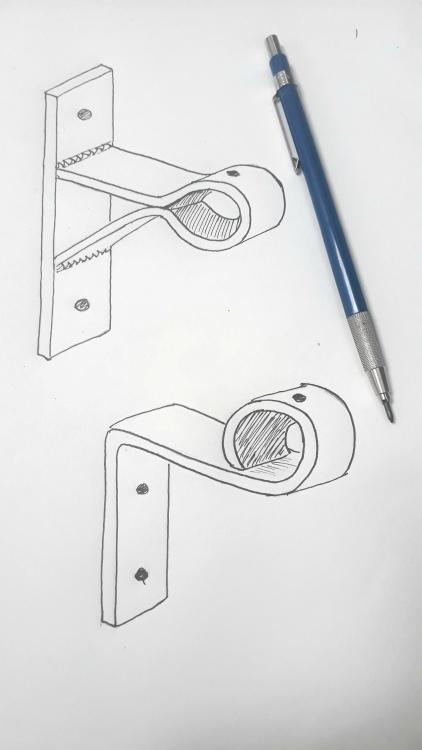

As mentioned by Thomas, with hollow poles my preferred method is to forge a tenon on the finial so the shoulder sits hard up against the end of the pole for as seamless transition as possible. Drill and thread a hole in the pole to accept a grub screw that will stop the finial from rotating but allows the finials to be removed if the clients to add/remove curtain rings. I've attached an old sketch of how I make the brackets. (Ignore the bottom sketch). The black circle on the top is another threaded hole to take a grub screw which prevents the pole from rotating or moving side to side.

-

Collars are typically closed around the items they are going to hold together whilst the collar is hot, the reason being that as they cool they shrink & grip tight. The collar material length is also usually pre-calculated so there is no overlap when folded around, or exessive gap between the butting up seam lines. Sometimes the ends of the collar material stock are tapered so if the material does overlap a little, the overlap isn't visible & the collar maintains the same thickness above the items being collared. In your video you seem to have forged it cold and have a large overlap, both will prevent a tight fit. It also seems like the central bar is thicker material, which creates a high point and gap under the collar & arguably doesn't help your cause. I have posted this video elsewhere on the forum in the past but it might help you as it contains theory as well as tooling ideas. A "bad language alert" seems to be the done thing around here to prepare the youthful and/or more sensitive souls.

-

From memory the thing that grabbed my attention about the Vulcan painting was the very clean white pot above the fire. They must have had non-dirtying ceramics back then.

-

I found mine the other day. Not looking it's best as it seems to have been under a bench collecting dust and dirt for about a year but you get the idea all the same.

-

What do you carry INSIDE your tool bag or box?

Joel OF replied to Glenn's topic in Blacksmithing, General Discussion

Ye olde battery grinder is the newest addition to my site installation and demo checklist. -

It wasn't strictly metal-origami but it was origami inspired... Essentially just half cutting through sheet to create a weak line to bend easily along, fold, fill with weld & grind back.

-

Thanks all. To be honest @BIGGUNDOCTOR I think I'm in the vast minority over here too getting work zinc sprayed. Dipping is a lot cheaper, and a lot of folks are favouring dipped then T Washed for that stoney grey-white look. @Lou L my coke forge isn't very big at all T.B.H. It's certainly not a big cast iron beast, the long heat is just a result of me stretching out the heat by feeding the bar backwards and forwards, pausing at certain point for 3 - 5 seconds at a time so I know I'm putting the same amount of heat into the bar along its length.

-

Haha to be honest I've never looked at the back of the container. It's £7 for 5L of Cementone Brick and Patio Cleaner. No idea how that rates in comparison to the stronger acids, but the appeal for me of this stuff is I can just stop on my way to work at a tool shop and pick some up. I read somewhere for the stronger types you need to buy at specialist places and prove you reasons for use? Possibly a load of rubbish but lingered in my mind anyway. I use it so infrequently I think in 2 years I've only used about a litre.