-

Posts

1,990 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Alan Evans

-

I had a friend, Jamie McCulloch, who always introduced himself as ...a sculptor who builds bridges... In the late 80s / early 1990s he developed a system for structural design and was given computer time at Stirling University to explore it. He would make up a physical wire frame structure and then dip it in washing up liquid. He then digitised the surface form of the bubble. The bubble obviously linked the frame in the most efficient way possible under tension and so was the optimum lightweight skin under compression. It was a similar-ish concept to the sand bags and string system that Gaudi used to plot the angles of his tilting pillars in Sagrada Familia and the Colonia Guell church. He would attach both ends of the strings to various points on a board representing the pillar bases on plan of the building, tie sand bags of scaled weight to the appropriate place on the string length. Invert the board so that the strings dangled at the angle determined by the weight position and photographed it. He then plotted the angle of the pillars from the prints. It enabled him to use monolithic pillars at extraordinary angles rather than be limited to vertical masonry columns. He also used catenary curves for his arches everywhere...and there are reports that these were plotted empirically. They actually hung a chain and plotted the curve on a board then inverted it to build the arch. I think he may have then made the monumental leap to the 3 dimensional system from that. Alan

-

An Encabulator...You never know when one will come in handy

Alan Evans replied to Alan Evans's topic in Everything Else

The original script was apparently written by the actor who was used for many technical film voice overs...he didn't understand a word of what he was saying so came up with the script in order to share his puzzlement... I came across this on another forum this evening and thought it too good not to be shared. If you look at the associated YouTube films there are a lot of variations, including the original. Alan -

All good. Total agreement. Everybody else has given the good advice to see a Doctor...so I don't need to...my own experience leads me to suggest seeing a physiotherapist. At an ABANA conference I attended in Saint louis Obispo at the age of forty, there was a session on backs and preventative measures to maintain them. The gist was that most people's backs can take abuse for forty odd years and then they complain. Three months after the conference mine went bang and I was bedridden. I was recommended a book called "Treat Your Own Back" by a New Zealand Physiotherapist called Robin McKenzie...ISBN: 978-0-9876504-0-5 I have been able to forge heavier pieces of metal after the event than I did before...it didn't make me stronger but it did not hold me back. A lot of the problem is bending forward over the anvil for protracted periods or slumped in chairs over a desk or in the car...you lose your lordosis, and the small of your back, which should be hollow, straightens out over the years. And as the back stiffens up with age, all the movement tends to take place between the fourth and fifth vertebrae which can lead to a bulging disc and pressure on the sciatica nerve and then muscle spasm to protect it. The solution to prevent and help that problem is to bend backwards often in order to regain flexibility over the whole spine so that each joint only has to move a little rather than one joint moving a lot. Hands on hips lean back and push hips forward is the intuitive response to a prolonged bent forward session and is the correct one. Do a wimps push-up...lie face down with your hands below your shoulders and leaving your tummy on the ground, arch your back by lifting your shoulders as high of the ground as you can without going into pain. Hold for ten seconds and relax and repeat a few times. Get a copy of the Mckenzie book if you can. You can check out the excellent and informative web site of one Sarah Key a physio based in Sidney who has developed similar exercise regimes based on the various permutations of back pain. Alan

-

I heard a nice story...Two experienced old explorers/travellers happened to meet by chance around a camp fire in the Hindu Kush. Could of been Wilfred Thesiger and Eric Newby...They got to discussing necessary items for exploration/survival and came to the conclusion that a "spoon with a sharpened edge" was the only essential thing required. I would make them from stainless so that you do not taint the flavour of anything you put in your mouth, you can leave them straight from the hammer so they will be black for reenactment appearances sake. If you know how to make a leaf by necking down the stem and spreading the lump on the end, that is all you need to know about the forging process, form a rounded end instead of a point before spreading. Look up leaf forging on YouTube if that is your only source. A dimple in the end of a tree stump or a soft edged hardy hole will allow you to form the spoon bowl. Be careful to avoid working the material too cold initially and avoid using hard edged tools to prevent any cracks or crevices which are difficult to clean. Smooth refined surfaces are the best for food stuffs/hygiene. So a final pass over the item at black heat will reduce the scale and rough texture. If you are splitting the fork with a chisel a file is your friend to remove any flash in the Vee. Alan

-

Olden Days, Old Ways

Alan Evans replied to ThomasPowers's topic in Blacksmithing, General Discussion

Slim Pickens...Yeehah! Alan -

Looking for Foundation plans for Nazel 4b

Alan Evans replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

You may be able to extrapolate from the foundation information that I posted here for the Massey hammers a while ago. Bob Bergman from Postville may be able to supply...or is a good bet for knowing where you may be able to get them. Alan -

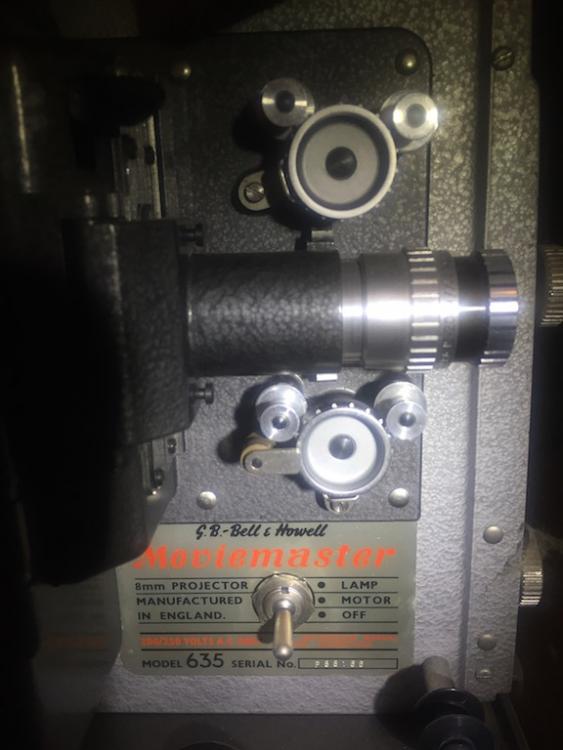

Film? It came in a few centuries after blacksmithing...both totally outdated mechanical technologies! Alan

-

Okay okay. Yes the teeth on the projector that followed me home one day, are convex-ish, but they are widely spaced apart and could not mesh with another...And film could be described as a wide spaced duplex chain....and...and I didn't say that it was a mutually exclusive definition anyway. I know this is a blacksmith's site and the camera assistant has to "clean the gate"...but I think that is pushing the association a bit. Alan

-

I know those are lovely and will make something interesting...and I know that sprocket is a lovely word to say and write...but the pedant in me says that those sprockets are gearwheels...convex tooth form rather than concave, made to mesh with another tooth rather than with a chain. Bet the wierdo alarm is ringing again...! Happy New year none the less. Alan

-

I think the energy source problem is very simple mathematics. Not sure where your political fraud comes in. Fossil fuels are a finite resource. It seems to me to make sense to conserve and eke out that resource by any means we can. Using Solar or Wind or Water, even if they are inconstant, and even if they are less economic in the current market, can make a contribution and reduce the fossil fuels burnt. When the fossil fuels do finally run out, it is not the time to commence using more energy to develop alternatives...do it now whilst we can do it cheaply. What is the problem with generating with solar when it is daylight and windmills when it is windy...and burn coal when it is not? Why dismiss their contribution because they don't conform to, or match the versatility of the fossil fuel model? Their overwhelming advantage is they are renewable which fossil fuels cannot match. In fact they will enable us to have power at night and on windless days for longer if they enable us to use less fossil fuel when it is daylight and windy...different, not better or worse. Alan This makes for an interesting few minutes... http://www.gridwatch.templar.co.uk

-

Interesting post. Why don't they just level the playing field with a fixed rate per kilowatt? Although I have always argued for net metering for domestic solar generation we do get this silly 50p per kilowatt hour payment which is unsustainable as far as I can see. It has paid for our panel installation in under 7 years. However it is only chicken feed compared to the guaranteed 90p per kilowatt hour that is available for those kilowatts created by the Chinese owned nuclear energy projects in this country. While the nuclear industry apparently received over 90% of the non fossil fuel subsidy (set up to support it when all the other power stations were privatised) it is interesting that all the complaints about green energy taxes over here are now blamed on subsidies to solar, wind and wave. Alan

-

Well I have had mine for 30 years, I will let you know when I finally get around to finding a use for it... Alan

-

Olden Days, Old Ways

Alan Evans replied to ThomasPowers's topic in Blacksmithing, General Discussion

I wish everybody a Merry Christmas and hope you all have a whale of a time....or should that be wassail of a time?...I am confused now. I trust nobody will bolt their food over the holiday, you will be nuts if you do. In deference to the OP, TPI would like to pitch an idea....that we bring this thread back on track, Alan -

Olden Days, Old Ways

Alan Evans replied to ThomasPowers's topic in Blacksmithing, General Discussion

How time and attitudes have changed, from olden days and olden ways.... The squaddies ate so much of it during the Second World War and always in clement weather....that they were fed up with it. Vera Lynn the "forces sweetheart" Sang a song about it...."Whale meat again, don't know where, don't know when, but I know whale meat again some sunny day..." Alan -

I have met some very interesting people in the blacksmithing world over the years and count virtually all of them my friends...one or two even from South Africa! Alan

-

My first meeting with Freddy in Lindau in 1980. He is standing with Alfred Schmidt and his wife, the parents of Gudrun Tischler who still works in the family forge in Trappenkampf. She is either third or fourth generation I think. The Sundial in the background is Freddy's. When I asked him how many men he had working with him he said "just the boy". When I asked how many colleagues he had drafted in to help make the sundial he said "just the boy"! Regarding his height and girth you should not feel too bad Tubalcain2, Freddy would have laughed with you. When he and Vaclav stayed with Dick Quinnel they did manage to get through a wine box between them of an evening. And his resulting snoring had to heard to be believed! A year or two after Lindau at the international conference at Hereford, during a visit to the Blists Hill museum at Ironbridge, one Dimitri Gerakiris pointed out that the delegates formed two distinct body shapes...there were those that were wider than they were high and those that were higher than wide...he managed to get the wider smiths into a line for a photograph, Freddy and himself included...the consolation prize for the skinny ones who were excluded, was that after the photo the "proper blacksmith shaped ones" did a coordinated mass jump for us! Freddy was a fine smith and teacher. I met him on a number of occasions over the years and he was always enthusiastic about both blacksmithing and fellow blacksmiths. My abiding memory, and one of the philosophies which continues to shape my work was when he said "Every hammer blow should be eloquent" I extrapolated that to every process employed should contribute to the spirit of the piece. Alan

-

Olden Days, Old Ways

Alan Evans replied to ThomasPowers's topic in Blacksmithing, General Discussion

Very good I have just looked it up. Typical border reiver skulduggery. The nearest I can get to your wife's grandparents is putting the wax polish on my maternal grandmother's Welsh dresser. Weak jokes aside, my maternal grandmother always said she was a true Briton. She had an Irish a Welsh a Scots and an English grandparent. Alan -

Olden Days, Old Ways

Alan Evans replied to ThomasPowers's topic in Blacksmithing, General Discussion

No it is not that sort of whale...it is more likely to do with wailing and gnashing of teeth...if it is anything to do with dogs and spitting. Alan -

Smithing hammer on steroids: video

Alan Evans replied to Lou L's topic in Power Hammers, Treadle Hammers, Olivers

I saw this recently on another forum. I was terribly impressed by the coordination and skill of the fork lift drivers. It is a pity the camera did not zoom out so we could see the actual hammer mechanism and the operator. I thought that given the small diameter of the con rod that it probably was a cable operated drop hammer. The scale of danger and the forces involved there renders most PPE ineffectual...a toe 'tector boot vs that ring? It would tend to take out the leg....if you were lucky! I was puzzled by the title though and wondered if "street" was a Google translation of the Chinese for "outside" Alan -

Reason of twisting under PH

Alan Evans replied to Gergely's topic in Power Hammers, Treadle Hammers, Olivers

Here are a few porter bars...as usual many of them made mid heat in a panic to counter a particular problem! As Glenn mentioned the rotation control bar / tell tale can just be a welded piece. I have often just bent the handle end of the workpiece at right angles to act as a rotation indicator. It all depends on the circumstances of the job. The banana problem is often encountered when forging from a bit of round stock. With square and flat you obviously always have a better control of rotation. Alan -

Reason of twisting under PH

Alan Evans replied to Gergely's topic in Power Hammers, Treadle Hammers, Olivers

What is your eye sight like? Get them checked. Do you wear glasses? Try single magnification rather than varifocals. Maybe get a new prescription. What light do you have at the hammer? Ensure it is even sided and well lit. What profile tools are you using? What action do you employ? Toby Hickman always uses a 90˚ twist back and forth with every blow...I could only do that on small bars/tapers, and even then sometimes managed to get it going lozenge or twisted. So I usually run along the entire taper in one plane and then rotate 90˚ and run the entire length again. I push in (thin to thick) if I am working with flat pallets and pull out (thick to thin) if I am using fullers. With a heavy bar long taper...if the tools are not well matched...or if you do not hold the workpiece at the correct height...and if you do not do a 180˚ rotation so that the bar is kept straight, a banana shape overhanging the bottom pallet can cause a progressive twist unless you have a good porter bar or Tee bar to counteract it. Practice...try deliberate twisting it to the right or to the left and note the results... Alan -

Things to do with wrought iron

Alan Evans replied to Bill in Oregon's topic in Blacksmithing, General Discussion

Mild steel...get it hot and hit it. Wrought Iron...get it very hot and hit it only while it is still very hot. Alan -

I will include it with your Christmas Card. Alan

-

A friend and ex assistant has decided to downsize and go in a new direction...(surf matts) and has asked me to take over his stock of Progen tool steel billets. Those three chumps are somewhere in the region of 100mm (4") square...the two on the right are Progen the longest bit is just over 3 metres. He also gave me the chumps of round mild steel and the Ø40mm (11/2") Stainless and two 40mm square mild steel to save them going to the scrappy. If anybody is looking for blacksmith friendly tool steel for hammers punches or power hammer pallets and dies get in touch! Progen is good for anything from cold chisels to razor blades according to the Seaboard Steel Co. Alan