-

Posts

1,990 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Alan Evans

-

power hammer treadle design

Alan Evans replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

Still here in the yard under a couple of bits of carpet. Yes the treadle movement on that is high and awkward. But like so many of these machines you get a working relationship going the more you use them. I haven't used my blacker for 25 years but what I remember is that you needed to show it who is boss with an initial hard push to overcome the inertia and then immediately back off to the blow weight you required. It was slightly counter intuitive but if you pussy footed around to begin with the first blow was extremely heavy and could make a mess of the job. Even after I came to a grudging understanding with the beast I would still put the first blow where it did not matter in case it reneged on me! Mechanicals eh? As I think I said earlier...once cycling though, it was incredibly regular and consistent, so for fine tapers/finishing it was better than any other hammer I have used. Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

As far as the hare-brained work practices go... I sometimes have a couple hammers and the press all running and can go from one to the other mid-heat as the process demands... Alan ps Sorry, just wanted to get hare-brained in... -

power hammer treadle design

Alan Evans replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

I have done the same. My hammers are raised and the treadles dropped for the same reason of being kinder to your back and keeping your heels on the ground for stability and safety. On the 3cwt I ended up putting a couple of hook on stirrups to take the treadle height down... Whenever I have a visitor that I let operate the hammer I stress keeping their weight on the back foot, so they can lift the operating foot away instantly...if they are using their body weight to push the treadle down they cannot get it off quick enough. On all the treadle operated machines...vertical presses and hammers I have built a safety shelf above the treadle to prevent them being operated inadvertently by a falling workpiece or stumbling blacksmith. Alan -

Removing Grinding marks

Alan Evans replied to ThorsHammer82's topic in Blacksmithing, General Discussion

I final polish a ground-flush weld with a 120grit sanding disc in the Ø100mm (Ø4") grinder and then blend over with the needle descaler. If you are getting really picky you can throw up a slight levee with a hammer instead of just grinding a weld prep on a butt joint say. Then even the weld undercut is ground out before you get to full size section...the number of times you see someone has ground the weld below the plane of the workpiece trying to remove the hair line undercut... The centre Ø50mm (Ø2")of a sanding disc is always unused and a 36 grit zirconium disc is a great matting texture device when hit with a hammer. Alan -

Removing Grinding marks

Alan Evans replied to ThorsHammer82's topic in Blacksmithing, General Discussion

I often use an air needle descaler to texture weld and ground areas...it reproduces the fire scale surface quite convincingly, and blends it all in. As a get around I have also hammered a bit of coarse grit emery cloth onto the ground/sanded surface which gives a slightly milder version of the texture. Alan -

tire hammer die heat treatment

Alan Evans replied to canada goose's topic in Heat Treating, general discussion

CEM DT-8859 is listed on eBay, presumably the DT stands for digital thermometer or similar...I found some around the £200 now. The company I bought mine from may have just bought a box full and was pricing them low to be rid. Look for Ianinsa's information on IFI though. Alan -

Nice job...of course once you have got the hammer in, you will be able to forge the bolts for the next one! You have learned of the advantage of tying on a coffee tin to create a concrete free chamber beneath the Tee-slotted plate so you can get the bolts in and out? This chamber should be deep enough in case the Tee lugs ever did shear off so that you can just leave them in there and still get another bolt into place.... Alan

-

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

Coincidently I posted an image of some bolt-on fullers to another thread a day or so ago...on the floor in the background there is a drop on tool I made up for a batch of elements which incorporates the stops required, the bottom pallet was exposed to work the largest section dimension. Alan http://www.iforgeiron.com/topic/48744-show-me-your-diy-dies/#comment-509592 -

show me your DIY dies

Alan Evans replied to c.baum's topic in Power Hammers, Treadle Hammers, Olivers

It tends to be what is on the rack...but I have them from 30x5mm up to 50x6mm I think...not at the forge today so can't measure. You can always make them longer if they are thicker. All my top tool handles are 30x5mm-ish...it takes the sting out if you have them tilted when the tup comes down. If made from square or round I would forge a flat area to act as a flexi-hinge to do the same job. Doesn't take many thumps to prompt invention! The flat spreads any pressure over your hand and is therefore more comfortable than the narrow contact from a square or round. Alan -

tire hammer die heat treatment

Alan Evans replied to canada goose's topic in Heat Treating, general discussion

Do a search on here then. Ianinsa gave a lead to a company in China who would supply them below £100. Maybe not CEM but an equivalent temperature range. They are available nowadays at this sort of figure just need to find the source. Alan -

show me your DIY dies

Alan Evans replied to c.baum's topic in Power Hammers, Treadle Hammers, Olivers

A new concept must be learnt with flat pallet work...the top tool will conform to the surface of the top pallet so they will be parallel when under load at any height...the spring will allow both height and axial movement...until a weld fails, which is par for the course....I find a wide and thin spring is most effective, the thinness gives for flexibility and little stress/work hardening; the wide gives good location and keeps the tools in line. Alan -

tire hammer die heat treatment

Alan Evans replied to canada goose's topic in Heat Treating, general discussion

An IR temperature gun will cost less than your trip to the heat treaters. They have recently come down in price for the higher temperature ones, a few years ago they were in the thousands of pounds. I bought one which goes between -50˚C and 1600˚C for £120 UK pounds from an Amazon UK link last year. Professional Infrared Thermometer - CEM-8859 ...they had reduced it to to £60 a few months later gggrrrr. At least it meant a couple of friends were able to get them at that rate a month or so ago... Alan -

show me your DIY dies

Alan Evans replied to c.baum's topic in Power Hammers, Treadle Hammers, Olivers

Now the fun starts! Download a copy of Lillico from the Hereford college website. Make a frame to attach a pice of 50mm box section at one end of the bottom pallet, use this hardy hole to locate your various direct forging tools. These can be either spring tools or bottom profiles. Each one requires a piece of 40mm box section welded to it as a hardy peg....lternatively drift the 50mm box section out with a 40mm square drift and use 40mm solid for the tool hardy pegs. I wrote about a firm/flexible fixing system here for attaching direct tools to top and bottom pallets... http://www.iforgeiron.com/topic/27911-steam-hammers/?page=20#comment-406040 The whole thread was interesting unfortunately many of the images seem to have got lost. The added fullers that were mentioned are shown here... http://dillonsculpture.tumblr.com/post/106060265305/overtime-in-santas-workshop This image shows my rubber tube mount plus the fullers. It also shows the bolt on hardy hole, and flip over spacer system. and in the background on the floor shows some composite drop on tools for specific projects. The most useful tooling system I found for my 50kg (110lb) Reiter direct forging hammer, which had a stroke of 200mm and therefore not much height for top tools...was a pair of cheese fuller drawing dies and a drop-on mild steel table which was around 175mm (7") square. Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

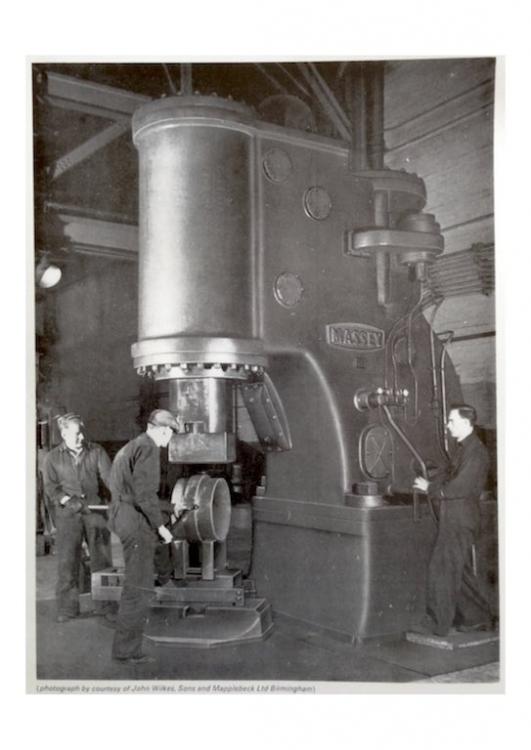

While doing a search back to find a post I made about fixing direct forging tools to the pallets for another thread I happened on this video of a "terrible" 40cwt Massey self contained hammer forging rings https://www.youtube.com/watch?v=3FcZ3GuvsJ0&feature=youtu.be ...actually the whole thread was very interesting I remember. Sadly it is one that has lost many of its images which probably lessens its value now. http://www.iforgeiron.com/topic/27911-steam-hammers/?page=1 -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

Second try. The pickling paste does work on forged stainless and works well preventing rust. I think it passivates by stripping away the iron molecules and just leaving the nickel and chrome. It leaves a very pleasant dull sheen. It is horrendous stuff to use...I double or triple glove when I am using it. I avoid using it if I can. Check out a safety data sheet for Hydrofluoric Acid, unlike virtually every other acid, soda does not kill it...you need lime I think. Do not take my word for it, please check it out for yourself. The electro polishing process is roughly equivalent in cost to galvanising...the shipping to the polishers/galvanisers is often half the cost. The great thing about electro polishing is that it puts a mirror finish onto every nuance of hammer blow and fire scale marbling on the surface. No detail is blurred or softened as it is by abrasive polishing, so it is a bright and "live" surface. By removing the microscopic high points the surface is less rough and stays rain splash free. It almost looks chrome plated. Very resilient, great visual contrast with burnished graphite painted iron. I usually use Renaissance wax (microcystalline and polythene wax blend) as belt and braces on stainless. Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

Fine by me...as an artist I would defend to the death your right to have an aesthetic opinion...however misguided I believe it to be! Well to the death might be a bit of an exaggeration...but I would remonstrate loudly, and be really cross if no-one took any notice... Funnily enough it was partially an opposite aesthetic opinion on my part to head away from the toggle action LG/Goliath hammers. I always thought of them as a bit Heath-Robinson...although I always loved his cartoons...just not for real work! Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

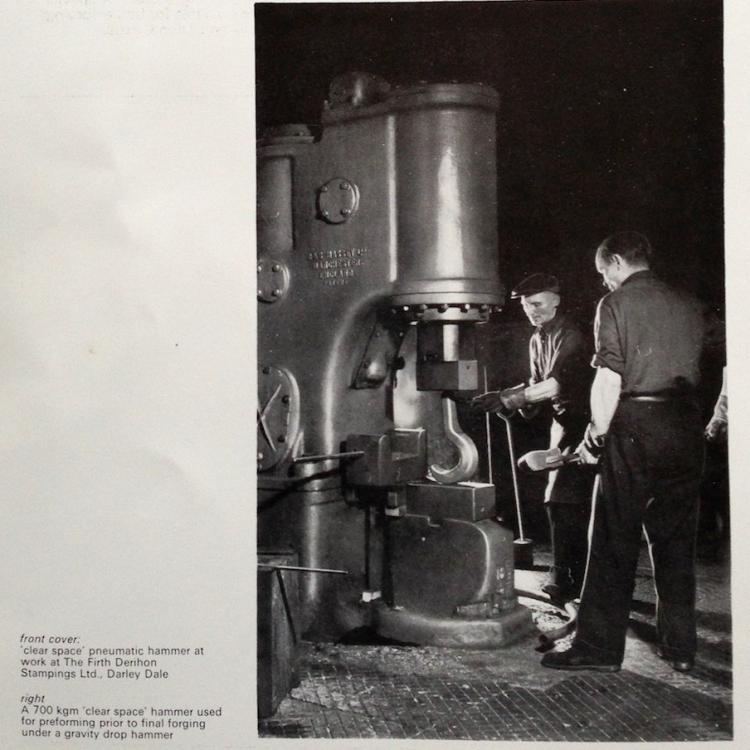

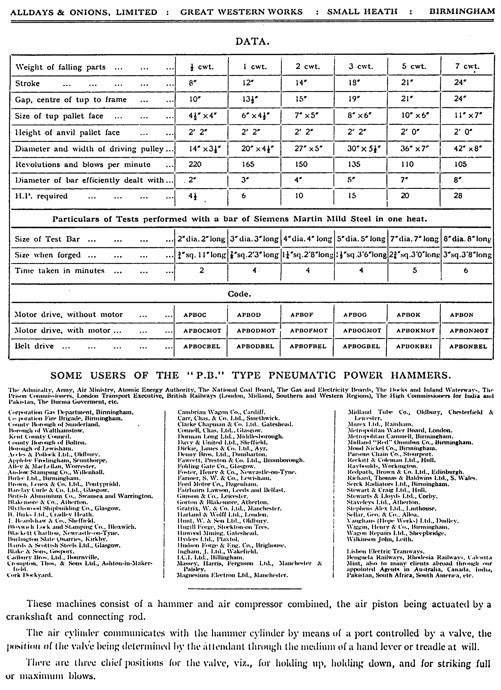

The whip lash blow must generate the maximum impact, as the elbows are coming closer together, and the tup is at its fastest. If in your example that optimum speed was achieved at 2" then `I can see that any blows on smaller dimension workpiece would be less powerful. The tighter the spring and the more rigid the toggle arm connection the slower the actual strike speed would be, irrespective of the blows per minute speed. Yes, more squeeze by slipping the clutch or deflecting the spring but less actual hot metal moved. The more rigid the link between crank pin and tup becomes, the less the maximum impact; the tup will actually be slowing rather than accelerating as does the vertical movement of the crank pin turning through the lower quarter of its revolution approaching BDC. I understand what you have been saying about the Murray's blows having less effect as the workpiece dimension reduces....and thus enabling you to keep the pedal to the metal and maintain your maximum BPM rate, with lighter blows on the workpiece as the tup runs out of stroke. Provided that the required dimensions of the workpiece comply and with the general tolerance of the live forging process I can see it could work well. In common with most hammers: hand, air, water or electro mechanical configurations the maximum impact of the Murray must occur with the tup cycling at its fastest speed accelerating over its longest stroke. This must be set to the size of the bar to be worked or a compromise made to maybe a third or half-way between the start and finish dimensions. Of course with the tolerance built in to the system this is not a deal breaker. But does mean you have to consider your processes well in advance and prepare the hammer accordingly to get the most out of it. The advantage with the air hammer is that you are in precise control of the weight of the blows without any concomitant loss of BPM, rather than the more nebulous relationship of BPM and blow weight when taking pressure off the pedal on the Murray. So using your dimension/taper example...any air hammer could generate fast heavy blows on the 1/2" section or anywhere in between...the Murray will not allow you to have heavy blows whether fast or slow on the thin end, without resetting. What I was musing about was a machine having the ability to actually increase the speed above that which is optimum for full power blows whilst simultaneously reducing the impact power. But as it stands I think the Air hammers have the most useful compromise for free forging. Apart from prompting an interesting discussion and learning about the strengths and weaknesses...I hope the OP has learned as much as I...my main argument has been with your "they're terrible machines" comment. I enclose some images of "mechanicals" which do not have the control or versatility of your 240lb Murray and some self contained air hammers that have considerably more! Alan Air hammers do only tap with their tup weight at the top of the stroke. Like all hammers...hand or mechanical they rely on the acceleration over their stroke to generate maximum impact. Otherwise they would be called presses. There is a huge difference however between the top of the stroke and the rated capacity of the hammer. My single acting 3cwt Alldays has a stroke of 18" but is specified to have a regular working capacity of 5" round material. You can hit a tool or a workpiece 18" above the bottom pallet but it will just effectively be with the weight of the tup plus a couple of atmospheres maybe 350kg (700lb). But I have happily upset pieces which were 10" high at the outset. Double the rated capacity and in the top half of the stroke. While it is true that the maximum blow an air hammer can generate is when the pallets meet…It does not follow that the upper end of the stroke is useless...it just keeps getting better the lower and faster it goes. Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

This post has crossed with yours Joel (sorry Mr. Sanderson, as you are being formal)....at first glance I see we have discussed a similar area...will get back when I have thought about it more! Hammer blows. A couple of things have been going round in my head prompted by this thread regarding the dynamics of various hammer blows. It will be apparent that I am not a physicist or engineer, the basis of my thoughts is more from empirical observation. The description from Joel/Clifton of the forearm squeeze / Murray hammer analogy is problematic for me. My understanding of the process is entirely the opposite. A die stamping drop hammer relies on its speed of impact rather than its weight to pass the energy through the material and fill the die. I am quite happy with the contention that the Murray style whip lash action does indeed cause the effect of the blow to affect further through the workpiece for a given weight of tup and speed of cycle. For this reason this style of hammer can give more bang for the buck....it is not a squeezing action when at its most efficient though. As I described in an earlier post the toggle arm spring is trying to pull the tup back up by the time it is striking on automatic blows, not squeezing it down further. The Murray would not displace anything like the amount of metal per blow when in push/squeeze mode as opposed to full power automatic blows. In that mode it only has the dead weight of the tup, the slipping drive system and the spring power to transmit the energy. A dedicated press working with tonnes rather than pounds is far better equipped to squeeze. The other thing which has been claimed is that the variable speed of the Murray style hammer is an advantage. I have no problem with variable speed...the problem is that the Murray style hammer does it entirely the wrong way around for efficient forging as far as I can tell. If you were able to speed up the lighter blows needed for working lighter section it would be logical. Lighter section material: lighter hammers: more blows per minute. Heavier section material: heavier hammers: fewer blows per minute. Applies whether hand or power hammers are involved. The only advantage of fewer blows per minute on light section I can think of is maybe you have a bit more time to position the workpiece to avoid hitting in the wrong place...but it is so in opposition to the normal forging basis of strike while the iron is hot. In respect of coping with both heavier and lighter section material, being able to vary the weight of the blow rather than the speed is the better compromise I think. It is shared by many (most?) mechanical and air hammer configurations. Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

Thank you for the reminder, I posted just before I went to bed this morning, and before I fell asleep I remembered a thread from a few months ago regarding Joel's machines. My input to the thread, you will note, has never been to deny that Joel's Murray will do what he claims. I have spent many happy hours with Clifton's tapes, watching them through at least three times over the years and writing a review for the BABA magazine. I have spent a few hours in the presence of the man himself at a few conferences and have had similar discussions with him. Joel's impressive resume and portfolio however do not back up the non-sequitur of his claim that all air hammers are terrible. You only need to watch the video of JNewman on page one of the thread to see how capable a machine in the right hands that is. Air hammers come in so many different configurations and with so many different intended applications that to group them all together is misleading and pointless. What they share is that they are driven by air. Equally the position that all mechanicals have the same facility as his 240lb Murray is palpably not true. A Federhammer is a mechanical, a Blacker is a mechanical, the smallest Little Giant is a mechanical, a tyre hammer is a mechanical, a Helve hammer....What they share is that they are not driven by air! My argument is not with Joel's hammer's capability but with his simplification to an artificial divide between differently engineered systems irrespective of any capability differences...and the need to rubbish anything. As I said earlier, I also believe know that any hammer is better than none...despite their differences in capability or versatility or appropriate application...they are all an advantage to a blacksmith. Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

Sorry your are right, I should have said, not appropriate for free-forging. I was in "versatility of one hammer to do it all discussion mode". Of course if it is production die work and you work within the throw, it is possible, and could be extremely efficient to manipulate hot metal with one. I am intrigued that you use one as much as your hammers though...what are you producing with it/what is your main business? And have you ever had one stall (which is the point I was making) while setting up for instance? But whilst picking me up on that you ignored the squeeze issue? Do you still consider the air hammer to have no squeeze? The whip lash acceleration of the Murray on full automatic I would have thought would have very little squeeze compared to an air or steam hammer, the spring is trying to pull the tool back at point of impact rather than push it forward. Alan -

Happy Halloween, blacksmithing related ghost stories.

Alan Evans replied to Daswulf's topic in Everything Else

My grandmother lived in London from the early thirties to 1980-ish and rarely left. I can only remember her once visiting us during my childhood. When I was in my early twenties she gave me a quarter chime mantle clock that my Grandfather had been presented with by his fellow Masons. I had it restored and my parents used it for a few weeks with all the chimes going...we then left the chimes unwound because they were so irritating, and continued to just wind the actual clock spring for the next decade. When my grandmother eventually had to leave her London flat she came to stay with my sister in the village. On her first day walk around she called in to say hello, and as she crossed the threshold the old clock chimes started up for the first time in ten years... Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

In that case...Please don't ignore something I said and repeat the same over-generalisations. You have a valid point but you are weakening it by not recognising that only a few mechanical hammers have the range of application of your Murray. Many are only capable of direct forging, they have been mentioned in this thread already. The Massey Clear Space has a greater range of blows and versatility than your Murray, without any fussy adjustment. Slipping the clutch on your Murray to give you a squeeze/push is not generating full power as you seem to imply, that comes from the flywheel effect of everything at full rpm. Similarly the Massey when it is in press mode is generating full air pressure into the plenum chamber and the valves are metering that behind the piston, sure it is only a few atmospheres but it is a large surface area piston, but it is not generating full power through full acceleration. All the air hammers, direct and indirect versions, give the squeezing blow you refer to, just like the Murray. The Murray would come to a dead stop if it did not have its spring arms to flex, they generate the squeeze. It is why you cannot forge with a toggle press...The air hammer hits the surface, the air pressure continues to build behind it delivering the squeeze just like the spring arms yielding, until the valve releases the pressure. Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

The sky could fall as well...but disregarding the fact that one of your toggle arms could fail, I think it a bit weak to compare versatility of one hammer but dismiss the versatility of another because of a possible mechanical failure! A far more likely scenario for a dangerous event with a hammer, air or mechanical....Any hammer with a foot pedal is in very real danger of having something heavy dropped on it, or activated by your foot should you stumble, even if you have a safety shelf above it. That is far more likely an event than the valve system should fail in such a way that the air pressure above the tup was allowed in whist simultaneously the air below was sucked out causing it to do anything other than gracefully sink to the anvil... I think you are struggling now... Alan -

How big of a hammer

Alan Evans replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

The Blacker works on a parallelogram principle which keeps the hammer face level with the anvil but that has a forward rolling blow. I still manage to get lozenge/diamond sections now and then on a vertical air hammer if I am not paying sufficient attention...and even sometimes when I am paying too much! I always thought that the relatively short tup guide length of the toggle hammers contributed to the lozenge effect even more than the rotation...especially after they have been doing it for a few decades and got a bit of slop...slightly off centre placement of the work piece and the top tool would rock over. Alan