Binesman

Members-

Posts

327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Binesman

-

Yes bubba i think db is far better than df. If money is less issue than effort chile forge are pretty much plug and play and very nice but pricey. Most forges that are <500 require bricks to close up the end (keep in mind require is a strong word they will work without them just not as well or as hot). There are homebuilders that will get you a more complete forge for less however quality is always a question there are a few up on etsy atm that are ready to go. Personaly i always recomend the build it yourself route so you learn what goes in to it and have an easier time fixing it if something goes wrong.

-

Im sure frosty and mike will be along soon to help and they have both forgotten multiples of what ive ever known about a burner. However air intake isnt your issue You are getting early combustion and the flame is firing inside your mixing tube. When you turn up the pressure you can see the flame jump to the tip of the reducer and it starts burning correctly. I believe a proper flare to create a better venturi should correct that however not 100% id wait for someone with more experience to verify that. In the meantime i might recomend grinding the threads off the business end of your coupler to try and reduce turbulance at lower pressure to get the flame to stay at the end

-

Will a few suggestions. 1. Use 2 lauers of 1" blanket not a single layer of 2". Should tou manage to get enough heat to the blanket to damage it enough to need replaced you only have to replace the top layer. 2. While the 2600 blanket will obviously hold up to more heat 2300 blanket is fine if you build the forge properly. 3. My recomendation on building the forge liner is. 2 layers of 1" blanket each layer rigidzed. A 3/8" thick layer of kastolite 30. Followed by a coating of metrikote. That is how i built my forge and its held up to everything ive thrown at it (keep in mind im teaching myself how to smith by watching youtibe and reading then adjusting to get it 1/2 ass correct THEN teaching my son what i kust learned) so my forge gets a lot of abuse. For the shell use what works for you. I used 10" id 10mm irrigation pipe but realistically the shell is just a shell do what makes tou comfortable.

-

I havent used a devil forge myself. However from there mayerial (where it states the blanket is new and packaged to be installed by you) and from what ive seen from people here on this forums. DF sends there blankets unridgidized and expects you to use them that way. To me that is a major health hazard.

-

Dont bother with itc. It doesnt hold up very well as a hptface and at 5x the cost of metrikote its a waste. Yes it is slightly better at reflecting the heat making it a little more efficient. However metrikote (i havent used plistex personaly bit from what ive researched it is as good as metrikote) is realy tough stuff and holds up to flux like a champ. I speak that from experience as ive only recently started attempting to forge weld and i think i use more borax then metal.

-

Refractory cement for a propane body forge

Binesman replied to Ali Ahmed Khan's topic in Insulation and Refractories

The advice already given is sound and it would bennefit you greatly to follow it. I will add ceramic blanket is a consumable. -

I can tell you one issue ive found using a bell reducer for a flair. Ia that the threading will cause to much turbulance and ill get ignition in the tube. I grind the threading off the "flare" side to prevent this.

-

Looks very nice. I have 2 siggestions for you. First it looks like your propane hose is dragging down your feed tube (appears to have a very slight bend could be im crazy also) add a support arm to hold the weight of the hose. Second is to order a pint of metrikote or plistex from wayne and give the inside a coating to allow for greater efficiency.

-

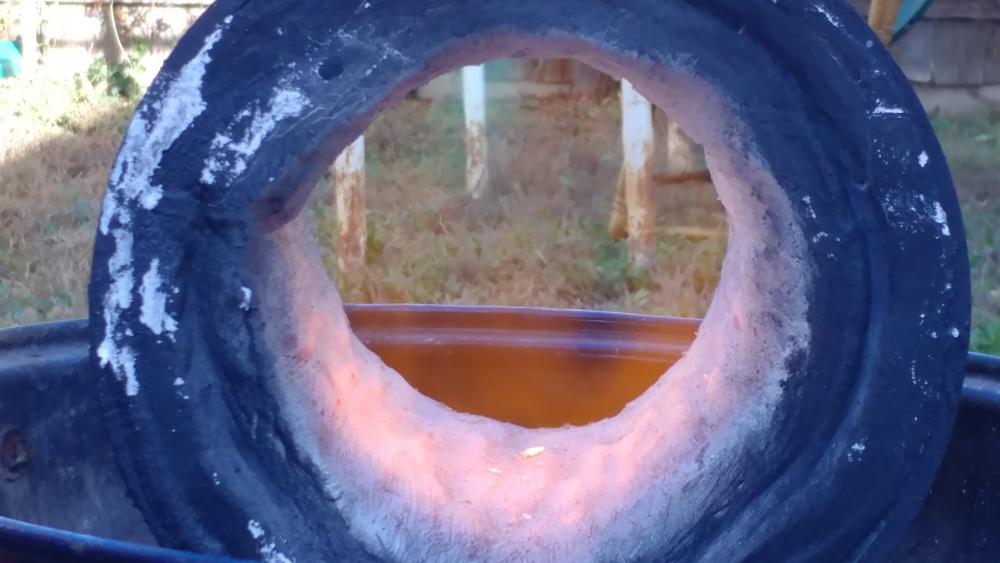

So my shoulder has been bugging me so no hammer swinging this weekend. I still wanted to be productive however so i made up a cpl new forges. Il still figuring out flame by the look. I think one of the forges is about right and the other is still a little rich. What do you guys think. Also sorry pictures where taken durring daylight so they are a little difficult to see.

-

I did you all a favor and set the bar really low

Binesman replied to Ohio's topic in Blacksmithing, General Discussion

Im from colorado...we have LOTS of funny looking leaves these days. However yours looks better and funner (yes grammar police i said funner) then the onrs weve had spring up. -

Welcome aboard. I can tell you i recently purchased ceramic blanket/kastolite 30/and metrokite from wayne to build a forge with shipping it was 90.us i then picked up a piece of 10"ID by 10"long 10gauge irrigation pipe (i would have prefered an old propane tank but the pipe was free) then vought the supplies from ace hardware to making a burner for 25.us. So for 115us and a lot of helpfull advice from the people on this forum (THANKYOU ALL) i now have a fully functional forge and the joy of using a tool i created.

- 15 replies

-

- forge

- propane forge

-

(and 3 more)

Tagged with:

-

Ceramic forge Lining safety

Binesman replied to Tucker Phillips's topic in Insulation and Refractories

That is a very reasonable price. As to your question ive never handled one of those forges so i couldnt answer. I will say picking up a pint or two of matrikote or plistix from wayne (google waynecoe) and coating it will not only alleviate your fear but make the forge more efficient. -

Burner is 10" long 3/4" diameter. Using a machined #60 hole to feed with 16 1/2" holes. I have made 4 of these prior to this one all work great. For some reason this one is running very rich. Any suggestions on how to correct this?

-

They will but it at $50. Per ton. Its not realy worth the work to scrap it.

-

No trade the only scrapyard in my area shreds any steel as soon as they get it. As for size its about 1inch round and 4 feet long and he has access to lots. So disapointing that i cant use it. But safety first and second and third.

-

Yeah after some research i found a Google referance stating that zinc will turn to a yellow powder when hot and turn white when cooled wich is exactly what this did. So tjat metals now trash not scrap. Ty for the quick replies

-

Ill have to take some photos. The coloration didnt look like any galvanizing ive seen. So i figured id give it a try. As soon as the yellowish powder showes up i removed it.

-

A friend brought me some scrap metal that has a goldenish bluish Hue to it almost looks like tempering colors when I put it in the forage and started heating it it formed a strange yellowish powder on the metal anyone have any idea what this is? And is this safe to use in the Forge?

-

Beginner seeking advice on a small propane forge

Binesman replied to EnthusiasticAmateur93's topic in Gas Forges

Throw some menthal nutdust aka goldbond on the underwear each morning and you get at least a month before they start smelling -

Thanks all. I was wondering about something like that frosty. Ty for the advice.

-

So my brother-in-law in Virginia has seen some of my recent Facebook posts. And he would like me to make a forge for him. I actually really enjoyed making my forge and burner and I'm happy to do so my question is this. My intention is to line the insulwool with kastolite 30 and matrikote just like I did my own Forge. If I do this before shipping will that coating survive shipping or just be broken to pieces?

-

Gene you can have a burner yp and running with nothing more then a dremel and a drill. Go to your local ace hardware get a 10 inch long 3/4" black pipe nipple. A 1" to 3/4" black pipe reducer. A 3/8" flare by 1/4" pip brass elbow and a 1/4" brass cap. For the dremmel you will need 80 grain sand paper rolls and a #60 drill bit. If you dont have a tap set youll also need a hose clamp On the 1" side of the reducer use the dremel to sand out all the threads and the slight "bump" to the step up so its smooth. Screw the 3/4" end on to the nipple. Then use the dremmel to drill a number 60 hole in the center of the 1/4" cap and connect it to the elbow. Drill 3 sets of 4 (total of 12) 3/8" holes starting about 3 inches from the top of the nipple (the top is the side with out the reducer) stick the elbow in the top with the 1\4" cap pointing straight down the middle. Either drill and tap holes or use the hose clamp to hold it in place. Hook your propane up to the 3/8" flare and youre good to go.

-

Google waynecoe artist blacksmith

-

So youre shell will be a 9" metal cube. My recomendation to you is 2 layers of 1" 8# ceramic blanket for the sides and top with a 1 layer of 1" on the bottom. (ridgidize your blanket 1 layer at a time)Then place a layer of 1 1/2" hard firebrick for the floor. Then trowell on a 3000f refractory like kastolite 30 over the entire inside and let it set. Then coat it all with matrokite90ac. That forge will do anything you want it to and be sturdy. As for vuying a burner theres a lot of options for a decent price mathewson forge isnt bad.

-

Mr wayne coe sells everything you need