-

Posts

9 -

Joined

-

Last visited

Profile Information

-

Location

-North East Georgia

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Naturally Aspirated Ribbon Burner. Photo heavy.

Alaric Powell replied to Frosty's topic in Ribbon Burners

Much thanks for that. Ah, that clears up one thing. The mig tips I sell at work are M6-1.0. Either way, I can tap it. What I don't already have laying around the shop, I can pick up at work before I leave. The dangers of working at a hardware store, pretty sure they get half my check back each payday... Thanks again. -

Naturally Aspirated Ribbon Burner. Photo heavy.

Alaric Powell replied to Frosty's topic in Ribbon Burners

I think we're good. I haven't lined or coated the forge, as yet the materials are in the mail. Two questions: Can anyone point me to the post for materials for the T-burner? Is there anyone in North Ga. Who has blacksmithing materials available for sale? I would go visit Wayne, but the current social situation dictates I should avoid contact with him. No offense Mr. Coe. -

Naturally Aspirated Ribbon Burner. Photo heavy.

Alaric Powell replied to Frosty's topic in Ribbon Burners

Right, so, I think I'm on the same page. If my test block has too many ports and thus has too little back pressure, I'll reduce the number of ports and spread them out over the surface, increasing the pressure and attempting to maintain the coverage relative to my flame face below. Which, in turn, will allow the radiant heat to reflect back into the forge with the assistance of the IR coating and bring the temp up (sooner?) -

For everyone posting their survival reserves, can I get some addresses. Just in case, you understand. ^_~

-

Naturally Aspirated Ribbon Burner. Photo heavy.

Alaric Powell replied to Frosty's topic in Ribbon Burners

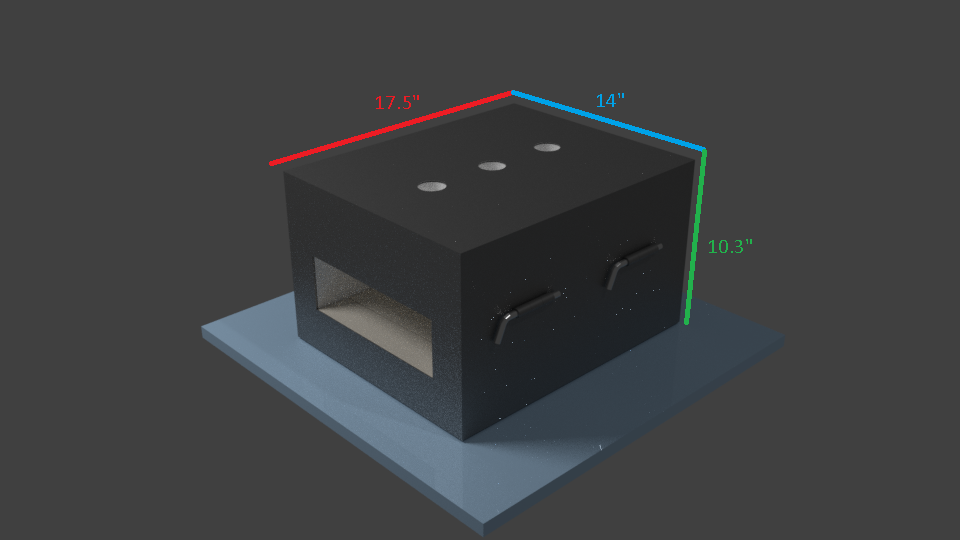

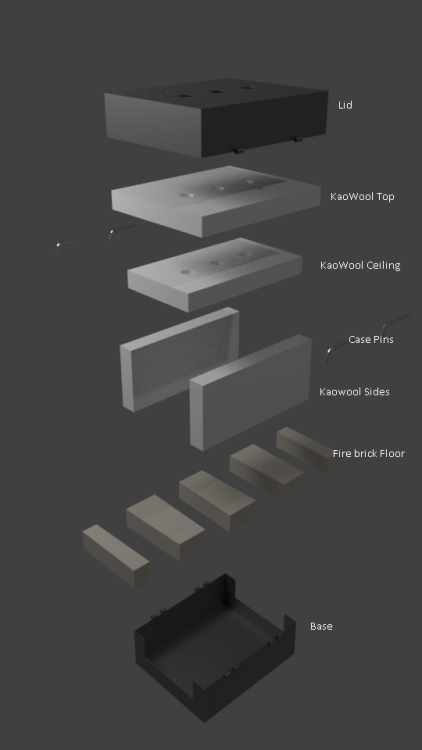

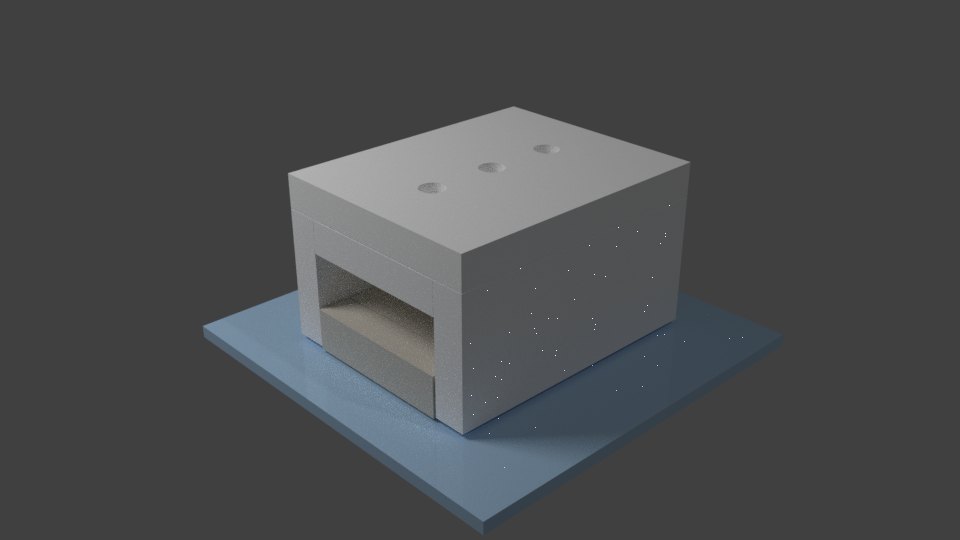

Wow, don't know how I fudged that SOOO bad (EDIT: I multiplied the DIAMETER instead of the RADIUS, OOF!) , was operating on V=πr²×L (3.14 x 16 = 50.24, x 16=803.84in³) The 7x11 interior would come out to about 423in³ (add salt because my math is rusty <obviously>) Anyway Link to 3D concept: https://skfb.ly/6RRMJ And Picture: the measurements below are Interior on the top box and Exterior on the cylinder body -

Naturally Aspirated Ribbon Burner. Photo heavy.

Alaric Powell replied to Frosty's topic in Ribbon Burners

Sorry Frosty, finally recovered the password for my original account. I'm building out of an old air storage tank (the kind you pump up with a compressor) it's 16" Long with a 12" Diameter. I cut both ends off so I'm left with an open cylinder. With both ends closed with soft IFB (obviously it won't operate fully closed ) and 2" of wool, rigidized and IR coated, the volume is +/- 3200 in³. The opening I cut into the top for the ribbon burner is 4.25" wide and 10.5" long (area of about 44.5 in²), leaving 2.75" on either end. I was planning on running forced air into the plenum as that's what Wayne suggests in his build, then I ran across this post and had to stop in to look. I really like the idea of being more portable without the need of a generator or other nearby electrical source. So, long story short. Before I start haphazardly welding things together. Do you think one of the MIG tip style delivery systems you like will perform well in this situation? OR, Do I need to scale down and use a smaller shell? Regards, Alaric Powell (AMPowell) -

Wayne, i''ll have to work some stuff out , but i would love to take a day out and visit your forge in the next few weeks.

- 15 replies

-

- forge

- propane forge

-

(and 3 more)

Tagged with:

-

Currently I'm in NE Ga. 'bout 4 hrs from you, Wayne Oh, and feel free to tear my design to shreds! I'm no Snowflake. The whole reason I'm here is to learn, and that works best if you have mentors willing to tell you where you're going wrong, I'm not trying to repaint the shop walls with my charred remains. Currently making my way through Mikes book. Took his advice from 101 and downloaded it from Scribd.com. The Design I made was based purely off what images I have seen online, with absolutely no Idea of the size/shapes that are required to A: Work, Period, and B: Work efficiently. I use Blender as a Graphic Designer and was playing with shapes; when I do know more about the process I'll more than likely, again, render it in Blender before I build it.

- 15 replies

-

- forge

- propane forge

-

(and 3 more)

Tagged with:

-

Hi all, New to the forums and to smithing. I see a lot of good info here, so I wanted to ask the question. To build or to buy? I've seen a lot of forges online priced $350 and up, that's a big pill for a newbie like me, so I was wondering if it'd be cheaper/smarter to build. I need everything for anvils to hammers and would like to be as economical as possible. So i did some googling, found this site, bummed around Amazon and eBay, and I noticed that buying the materials plus shipping as about the same if not more than buying a pre-made forge. Now, all I looked for was sheet metal, Fire brick (3k degree), KaoWool, and rigidizer. No itc-100, and I figure I can make some Sodium Silicate Glue. The big questions I have are: Can the Perlite-n-Playsand DIY bricks hold up to the heat as well as the Factory made? Is there a DIY KaoWool equivalent? Is the ITC necessary on the forge walls/Ceiling? I have a supply/warehouse within 15 miles of home so sheet metal and Stock shouldn't be an issue. I have drafted a forge design from some pics I have seen around, I also have several tanks around the house (Propane, air tanks, Grills) that I could chop up If my design isn't feasible, seeing as I built it around what I found on eBay for what looked like cheaper than average prices.The bricks I found are keyed so one would need cut in half to square the ends for the forge floor. The inner cavity of my design seems to come out to: 9.5"W x 3"H x 17"L Pics ahoy and thanks for the help in advance! Cut Key Brick Layout.bmp

- 15 replies

-

- forge

- propane forge

-

(and 3 more)

Tagged with: