-

Posts

88 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by WoodnMetalGuy

-

Chrome plated chain for hold-down?

WoodnMetalGuy replied to JHCC's topic in Zinc, galvanized, and coatings

That should hold it! But seriously, I can't help with the real question on the hot chrome - hopefully someone will chime in on that... -- Dave -

Chrome plated chain for hold-down?

WoodnMetalGuy replied to JHCC's topic in Zinc, galvanized, and coatings

Hmm.. How heavy is the dog? -

The ones used around here are a continuous wrap, maybe 3 or 4 times around the bale, and not tied or laced. So a knife would need to cut through several layers of net. -- Dave

-

Anvil identification. USA IAF

WoodnMetalGuy replied to Halphwit's topic in Anvils, Swage Blocks, and Mandrels

Anvil Shaped Object. Derogatory term for a lump of cast iron... -- Dave -

And here I was trying to think what 'little yellow flower' might be in Latin...

-

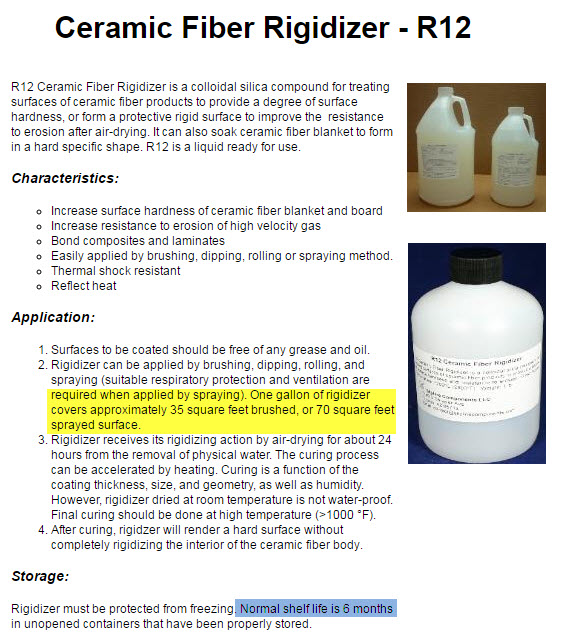

Found an answer for the coverage question at this site: http://skylinecomponents.com/CeramicFiberRigidizer.html So if brushing on covers 35 sq feet, I would only need 1/10 of a gallon... -- Dave Interesting, Frosty. I hadn't considered that it could be used between layers to glue them together, I was thinking this would just be needed on the innermost face to provide a firmer surface for a thin refractory coating. -- Dave

-

Mberghorn - At this page: http://www.sheffield-pottery.com/KAOWOOL-THERMAL-CERAMICS-RIGIDIZER-p/tcr.htm, I found this information: Physical Properties Color clearSolid content, % silica (approx) 28 - 29Weight per gallon, lb (kg) (approx) 10 (4.5)Nominal density, (wet), pcf (kg/m3) (approx) 75 (1202)Maximum temperature rating, °F (°C) 2300 (1260)Freezing temperature, °F (°C) 28 (-2)Viscosity, centipoises @ 25°C 4Specific gravity @ 25°C 1.203pH 9.7 So, since water is about 8.3 lbs/gallon, looks like they've got about 1.7 lbs of silica in there. I mix colloidal silica with epoxy as a thickener in my boatbuilding projects, and that stuff is almost weightless - it would take a bunch of it to make 1.7 lbs. And it's nasty to mix, floating off into the air with little encouragement. Overall, it may be better to just buy the pre-mixed rigidizer. My only concern is that at this time in this part of the country, I'm worried about it freezing in transit, which is something that's best to not happen for some reason. I may have to wait a bit before ordering mine. I'm also confused about why this stuff would have a shelf life. I would have thought it would be good indefinitely. Anyone know? Also, I wonder what the coverage is for a product like this? I'm sure I would need less than a gallon. Calculating inside area, less the shelf, plus the ends, I expect to need to cover about 3.5 sq feet. -- Dave

-

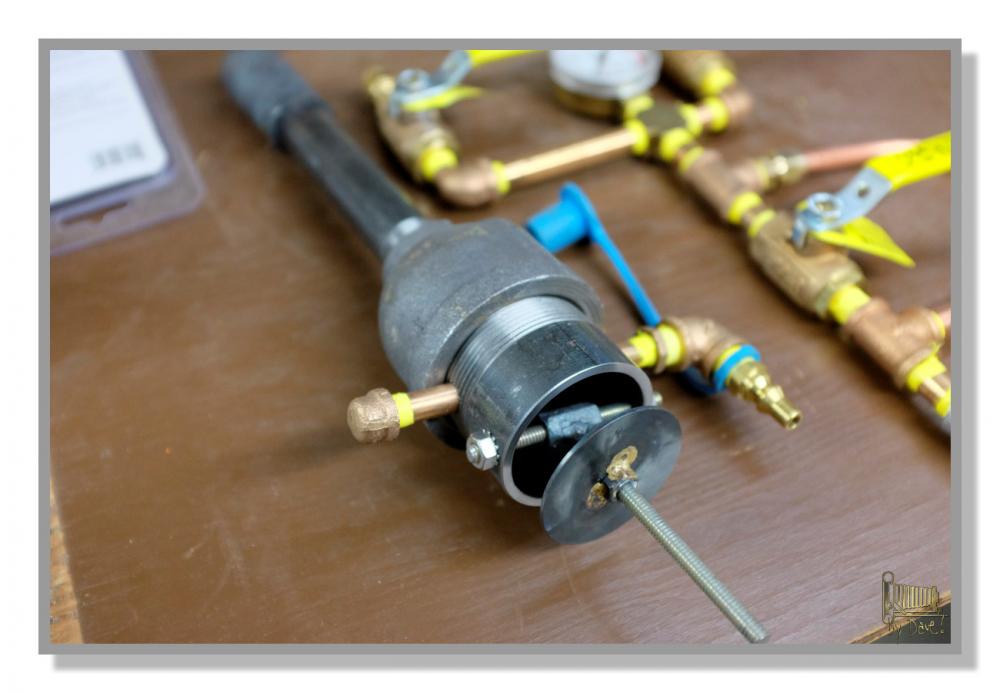

See this page for some information on the flare: http://zoellerforge.com/flare.html I made mine out of a section of pipe the size that fits over 3/4". Made a form with 12 degree taper on the metal lathe, and heated and pounded until it was flared the appropriate amount, which is not much, maybe 1/8" wider at the mouth end. -- Dave

-

What did you do in the shop today?

WoodnMetalGuy replied to Mark Ling's topic in Blacksmithing, General Discussion

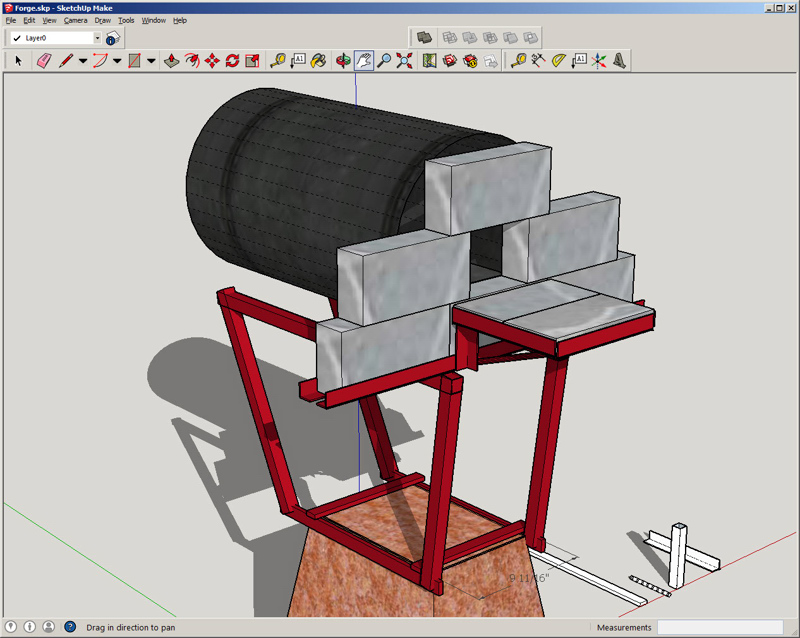

The free version of Sketchup is sufficient for a lot of design. And once you figure out a few tricks is not terrible to use. I just taught myself in order to layout my propane forge design - needed to figure out the shelf for the firebricks I will have instead of a door, and the support for a little hard firebrick shelf out front, and the frame supporting this all. It helped in the visualization process, vs. just starting to weld stuff together... -- Dave -

I also ran into that issue, but the threads on the first ones I got turned out to be metric. I have not heard of a 1/4-27 thread before. -- Dave

-

Forced Air Forge (NG) - Pipe Size, how small can I go?

WoodnMetalGuy replied to Andy98's topic in Gas Forges

I wonder if you'd have better control with a regulator in the feed rather than trying to control the gas with a partially opened ball valve. And an unrelated question - what's up with all the funnels hanging on the fence in the background? -- Dave -

It's a ways from you, but I got some recently from Continental Clay in north Minneapolis, MN. -- Dave

-

So you are thinking 3 layers of the 1" thick blanket? That's what I will be using in my 14" diameter shell. I remember that's what Ron Reill had recommended on one of his pages. The bottom will have 2 layers, topped by the 1" kiln shelf. -- Dave

-

I got my quick connects and needle valve from here: http://mbsturgis.com/torch-lp-hoses-and-accessories/quick-disconnect-and-accessories.html -- Dave

-

Not that I know it all, but I'm learning... Regarding sealing the threaded joints, I believe the tape for gas use is yellow, vs. the white that it looks like you've used. The white is for water plumbing. I don't know for sure the difference, may be a different material or a thickness thing? Anyway, that's a spot where it's just as easy to use the right stuff. -- Dave

-

Xamm940 - I'm also in the process of building a gas forge, and one thing I'm being careful to do is use gas-rated components rated at the appropriate pressure. The first thing to know is that ball valves are water (plumbing) or gas rated. What I didn't know initially was that the common gas rated ones from Home Depot etc. are for appliance gas lines, typically rated at 1/2 PSI. It takes more looking to find one rated above that. Looks like the one shown in your photo is rated for high pressure but I can't be sure. Similarly, quick disconnect fittings come in air (like for an air compressor) and gas ratings. Finding the gas rated ones is harder. In your photo the quick disconnect looks like it might be an air fitting, and I don't think you want to be using that in a propane line. Is that block with the knurled handle a needle valve? That could be useful in a bypass circuit to provide an idle level flow of gas for when you've taken out your steel and are banging on the anvil, but if you're using that instead of a regulator to control gas flow I don't think that's best practice. Also, you may want to find this book: "Make: Fire" "The Art and Science of Working with Propane" by Tim Deagan. It starts out with the very basics and progresses from there, and I've learned a lot, and feel comfortable with my setup. Recommended. -- Dave

-

Thanks for that input, Wayne and Clayton!

-

Clayton - I'm also in the midst of building a propane forge, and have the Kaowool and ITC-100 on hand. But I was wondering if a thin shell of refractory (1/4" or so) over the Kaowool before applying the ITC-100 would be a good idea to protect the fragile wool. I'm thinking the ITC-100 is going to make a pretty thin layer, and may not provide much protection against ham-handed metal handling. Your thoughts on that? Thanks - Dave

-

Yes, happens to me too in the spring when a warm humid day comes along and hits the cold steel. As far as I know the only solutions are to keep the humidity out, or keep the steel warm. Hard to do in your situation... -- Dave

-

That's a good point, Buzzkill. Overall, I'm wondering whether this burner is going to work out for a forge Looks like all the combustion air has to come in through those little slots, and it the area there is pretty small compared to the area in my home-built burner. Maybe won't be able to get enough heat of of that burner? -- Dave

-

20 psi is pretty high pressure. May be blowing itself out. Try it with a lower pressure and turn it up gradually to see how it handles it. Do you have specifications from the torch that recommends what pressure it should run at? -- Dave

-

Looks nice - I wonder what kind of steel that is? Did you have any issues overheating it while grinding it to shape? -- Dave

-

I'm just in the midst of a propane forge build and here are a couple photos from mine. Burner design is from book "Make: Fire" "The Art and Science of Working with Propane" by Tim Deagan. It starts out with the very basics and progresses from there, and I've learned a lot, and feel comfortable with my setup. Recommended. The shell I'm using is 14" diameter and will have 3" of ceramic fiber insulation. The kiln shelf bottom sits on kiln shelf risers, which are hollow and fit over studs I welded to the shell. Plumbing has an idler circuit, all gas rated valves, and took multiple trips to Menards before I rounded up all the right bits! -- Dave

-

Some older garage door openers used chain in the lift mechanism that is close to if not the same as some bicycle chain. If you can find someone scrapping one of those you can get about 14 feet of chain that way... -- Dave

-

You're too good! Looks mass-manufactured on that side. Good thing you left the interior rough so we know they're hand-made! -- Dave