-

Posts

170 -

Joined

-

Last visited

Contact Methods

-

Website URL

bobasaurus.imgur.com

Profile Information

-

Gender

Male

-

Location

: Colorado

-

Interests

Woodworking, blacksmithing, computers, bicycling.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I made this as a gift for my father, it's a hammer used for shaping shallow bowls/dishes out of sheet metal in jewelry work. O1 head, Tasmanian blackwood handle.

-

What did you do in the shop today?

bobasaurus replied to Mark Ling's topic in Blacksmithing, General Discussion

That forged meat tenderizer is genius, never seen one like it. I forged this jewelers blocking hammer head out of O1 drill rod last week, and got the faces dressed and polished today: -

What did you do in the shop today?

bobasaurus replied to Mark Ling's topic in Blacksmithing, General Discussion

Made this shoe horn as a late Father's Day gift for my dad. Forged from 3/4" mild steel rod, walnut handle. -

What did you do in the shop today?

bobasaurus replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a quick damascus bottle opener this weekend from a scrap cut off from another project. It has some imperfections but it came out okay. I also converted my steel bowl into a headphone stand (with my very first forged leaf). -

Thanks a lot Hans, I'm still a novice at welding and only intermediate at forging. What is a welding post? Using a regular grinding disc is a good idea to get the humps down first. Might give this a try. Les, is a pipeliner disc just a slightly thicker cutoff disc that you can cut and grind with? Good idea on the weld speed, one problem is my little welder isn't rated for this thickness (should have preheated).

-

Any recommendations on how to clean up a weld like this? Maybe flap sanding disc on the angle grinder?

-

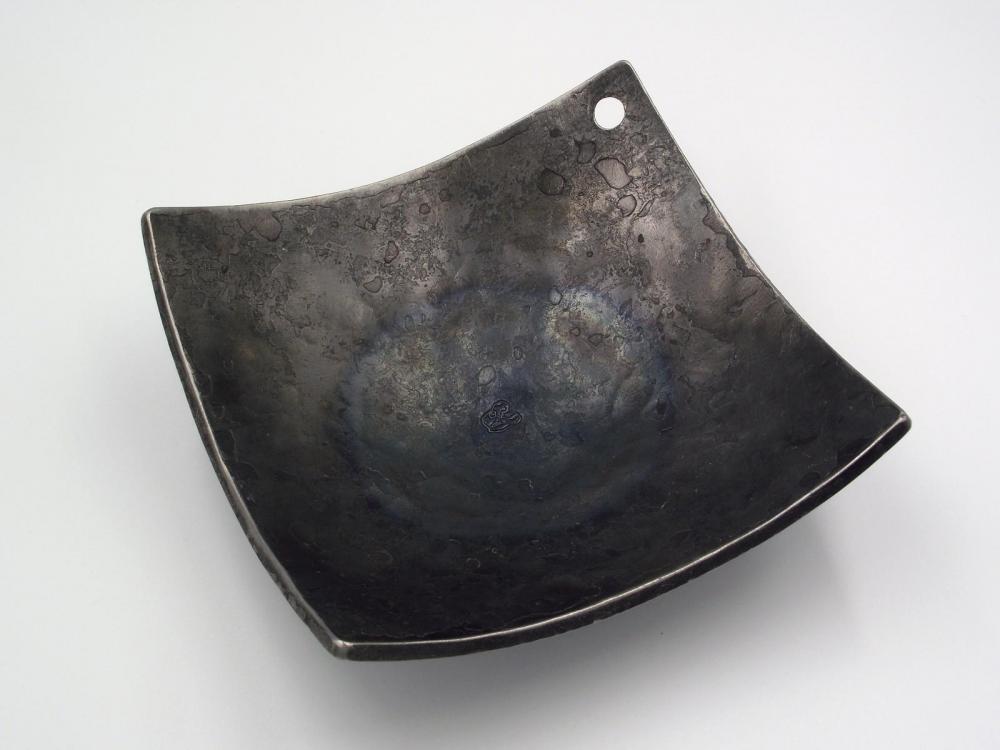

I forged this square bowl today from some scrap plate steel. Made a ring for the base and welded it on (terribly). I like how the welding heat colors halo around my touchmark.

-

I forged this kitchen knife out of 5 layers of metal forge-welded together, using the “go mai” technique (my first attempt at it). The outer cladding is 15n20 steel (from an old sawmill bandsaw blade), the shiny line is nickel shim stock (scrap from my workplace), and the core that makes the cutting edge is 1080 steel. The blade is fully hardened and tempered to a hardness of about HRC 60. It has a full flat grind with a 25 deg cutting edge, and is acid etched to show the contrast of the nickel layer. My logo is electrolysis etched on the side, though it is subtle with the black finish. The handle is made from cocobolo and has a piece of aluminum for the bolster. It has a hidden tang construction, pinned with brass rod. I’ve been refining this handle shape over a few previous knives and settled on this profile as my favorite. I finished the wood with several coats of amber dewaxed shellac, then a few lights coats of renaissance wax. This was a gift for my coworker's retirement, gave it to him yesterday and he seemed quite happy. I was a bit nervous as they passed it around the room, as people don't realize just how sharp a knife can be. Here are some progress pics of the build:

-

What did you do in the shop today?

bobasaurus replied to Mark Ling's topic in Blacksmithing, General Discussion

Here's a magnet tester I made for heat treatment. Has a scroll handle and a magnetic tool-holding stud welded onto the business end. Hard to weld a magnet without destroying it, had to keep most of it in water while welding. -

O1 also sparks weird... looks like mild steel.

-

My friend saved me some scrap chain, gears, and axels/shafts from his workplace. The heavy double-strand roller chain makes for a great hold down, and the hammer head I'm working on is from one of the shafts. No idea what steel, it was 1 5/8" diameter.

-

Wow, how do you find that much coal in the wild? Did you have to dig it yourself?

-

Wood turning parting chisels

bobasaurus replied to BeaverNZ's topic in Chisels, Gouges, Scissors, etc

These are beautiful, well done. What heat treatment do you use to prevent them from breaking on a lathe catch? -

It was a crazy place to wander around, here are some pics of the inside. That same day I went to the sawmill and bought some nice pieces of hardwood (two maple legs, a maple stretcher, and a russian olive top) to make a side table for my bed. I'll have to think about forging some hardware for it.

-

So today I found a flatter in what must be the least likely possible location... a prop warehouse having a going out of business sale. It was part of the mining display props. Bought it for $20, thought it was a great find (been wanting one for years). They had welded a tab to it for positioning or something, should be easy to break/cut-off and reface. It was surrounded by giant tiki heads, mummies, pirate ships, leprechaun gold, and all sorts of miscellaneous bizarre crap.