-

Posts

271 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Dustin Quade

-

The anvils edges look better kept then both anvils i have purchased i would say that you made out quite well for free no matter the brand

-

Can you get some close up pics of the sides where you said you think you might see letters?

-

I have only sold a few knives and all of them had small imperfections but the thing is no one seemed to care. i pointed them out and for the most part people didnt notice anyways or said that they liked it because it showed that the knife was hand made. Now im also not charging extravagant prices or anything and im very up front about the quality they are getting before hand. So i guess it really depends on you. If for you your stuff needs to be bang on perfect well there you go, gift defects to friends or maybe donate it to a charity auction or something. For me though the defects have never been a huge issue.

-

So over the summer I received a few commissions for knives some people wanted as Christmas gifts. The knives are supposed to be kitchen knives and while the shape is still the best I have managed to date I still feel there is something off with them though I can’t quite figure what. I made 4 this week 1 is still needing heat treat etc. and I will post picture of it once I actually get the heat treat done. In the mean time here are some pictures of the 3 others. 2 of them are ladder pattern Damascus and the other is an unknown pattern if anyone recognizes it please let me know. As usual I have taken these up through the grits, 60, 120, 220, 400 and then I etched them for 2 hours in double strength cleaning vinegar. The 4th one I’m hoping to try in coffee to see what that pattern comes out like. All in all pretty happy with the size and shape of them but as always critiques are more than welcome.

- 4 replies

-

- ladder pattern

- unknown pattern

-

(and 2 more)

Tagged with:

-

That a pretty slick looking first rasp knife well done. I really like the shape of the handle on it.

-

I love that style of knife but they are illegal here. Even so i am always tempted to make one just to see if i can. Love your work as always.

- 14 replies

-

- push dagger

- san mai

-

(and 1 more)

Tagged with:

-

Anvil Insanity Everywhere

Dustin Quade replied to ThomasPowers's topic in Anvils, Swage Blocks, and Mandrels

It has been my experience that patience and speed are the key to anvils these days. I got my first anvil for just over 2 dollars a pound 4 years ago now (93 pounds for 200$) and I got my new anvil for just about $1.40 a pound (179 pound for 250$). In the four years between those purchases though more often than not I see people selling anvils all in the range of 4-5 dollars a pound and you know what man those adds don’t stay around long. There are a heck of a lot of people getting into this craft which is great in some respects especially in the community that has grown around it and the ease of access for information about the craft. The downside is that prices seem to legitimately be going up with it. Supply and demand is the law of the land and that’s fine I get that. It’s troubling to me because I can’t afford these new prices as being the norm. If something happened and god forbid someone stole my equipment or it was lost in some sort of accident I literally could not afford to get back into this craft for a while until I had set some money aside. But I do understand why some anvils are becoming legitimately more expensive What bothers me though are the people being taken advantage of by this, lots of people don’t know what to look for when they are buying anvils and think cracks and dings can be fixed with some welding rod or similar. They don’t know how to tell the difference between cast iron and steel and they get taken advantage of. People selling anvils with missing horns or broken off heels like they are brand new. Now I get it, these tools still have life in them and they can still be used but the prices for these seem to be just as high sometimes as others and that’s what I don’t get. Another thing I don’t understand is the reluctance to just buy a new anvil. There are people selling them all through the US and even here in Canada you can find them. And with prices being what they are today why wouldn’t you just buy a brand new one? The entire advantage to buying the older beat up anvils is that they are cheaper because they have been used, my newest anvil has rough as heck edges because someone went to town on something cold all over it, the hardy hole is also quite indented from hard working and the very back of the heel has a tiny torch mark on it, but I got it for less than half the price of a new anvil of the same weight so it’s not such a hard pill to swallow. But the one used at the start of this thread for example is 150lbs and they want 1100 bucks or for 1200 bucks you could go to blacksmith depot get a 165lb peddinghaus anvil brand spanking new. I just don’t see how someone can with a straight face ask 1100 for that older one. -

Yep thats what i figured after looking at the dimensions of some other anvils. Still super happy with it, if it was heavier though it would have been a crazy crazy deal

- 9 replies

-

- pounds?

- english weight?

-

(and 1 more)

Tagged with:

-

As promised some pictures of the new anvil. Face is just over 4" wide, its 12" tall and the flat face is 16" long. I didnt think to measure the horn or anything.

- 9 replies

-

- pounds?

- english weight?

-

(and 1 more)

Tagged with:

-

Lol that does sound like a heck of a good system. I think this one will do me for quite a while as my home anvil and my old 93lb peter wright will become my portable anvil. As much as a 300lb+ anvil is something i salavate for i will be happy with what i have now. I do need to clean the edges up a bit on it. Does anyone know a video showing a good way to do so? I dont mean like welding up edges. I dont have the skill or tools for that. I mean just trueing them up a bit with maybe an angle grinder or something. Im just not sure what the edges whould look like all i know is that the edges here dont look like they should.

- 9 replies

-

- pounds?

- english weight?

-

(and 1 more)

Tagged with:

-

My bathroom scale is made of glass and as strong as i am im not feeling confident in trying to lift this thing and gently place it on the scale. If it does break my GF will be quite upset :p. You answered my question though i think. Must be pounds. It cant be KG because i was able to lift the thing and im not sure i could lift 395lbs lol If it was 317 i would have been super impressed with myself lol

- 9 replies

-

- pounds?

- english weight?

-

(and 1 more)

Tagged with:

-

So i just picked up a Hennry Wright Anvil. It is marked on the side as 179. Does this manufacturer use the english weight meaning its a 317 pound anvil or is that normal pounds so just 179. Either way it was a good deal and a marked improvement in weight over my current anvil but i want to know just how good a deal lol. I will post pictures after work.

- 9 replies

-

- pounds?

- english weight?

-

(and 1 more)

Tagged with:

-

I like the idea you had for the handle there. For brushes the easiest thing is to buy a brush with a wood back and cut the handle off and shape the wood piece so it looks good.Then you split the bottom of your poker bar in two, you then open it up and flatten the split as much as possible so its like a capitol " T "shape. draw out the two tines into similar shapes and punch two holes which will be used for screws to affix the brush. now do your handle like normal and then attach the brush and your good to go. i hope that all made sense.

-

I am a huge fan of everything to do with that handle the shape looks really impressive and the material you chose is simply beautiful. The blade shape is my favorite part i think. Nice choice of material for the guard though if it had been me i think i would have gone with brass to match the pin you used or swapped the pin for maybe a mosaic pin with steel. All in all the knife beautiul and you should be super proud of it. I know you said guard doesnt fit as tight as you wanted but for me personally i like little imprefections in my work like that.

-

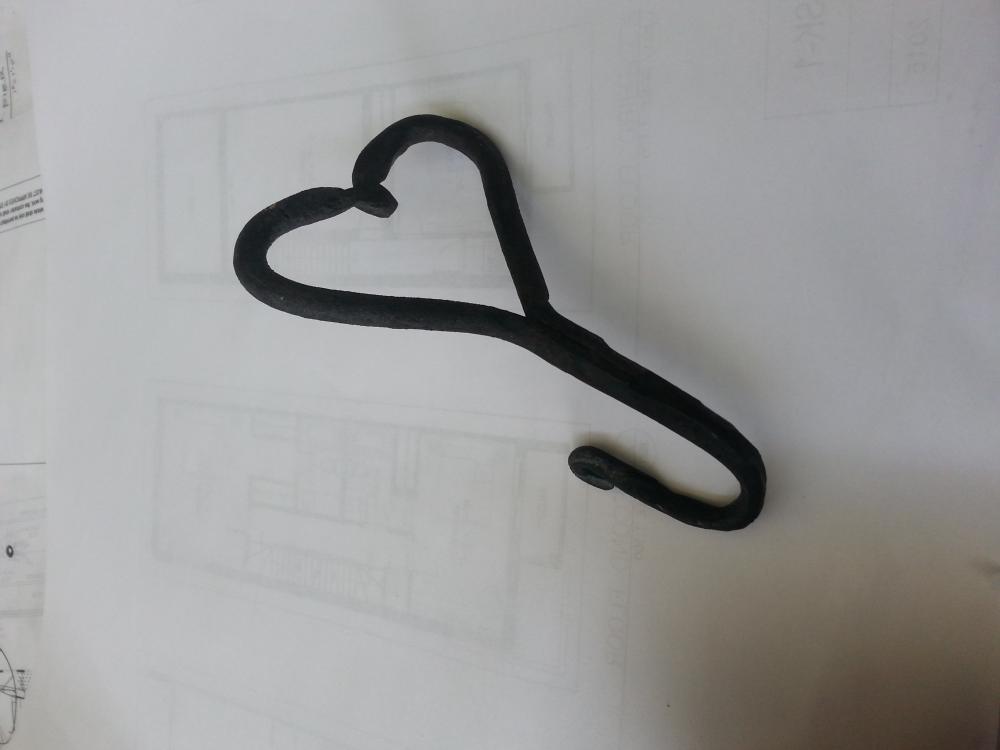

Hey Forsty Yea the heart isnt perfect, i especially messed up the part where the two curves of the heart meet. It was supposed to be a very shallow taper but i went pretty deep which made for this odd twist to happen after the fold over. I luckily do have a swage block but thats a pretty good tip if im to lazy to dig it out lol. I did flux the cable just with regular borax. The man who did the demo did not use flux but he said his was the cocky way to do it and said that flux was not a bad idea for those of us not comfortable forge welding. They actually said they rarely use flux, one guy said he never ever does.

- 2 replies

-

- success

- forge welding

-

(and 1 more)

Tagged with:

-

This weekend my local blacksmithing group held a forge welding workshop for 2 days. The projects consisted of flux spoons, fire pokers, chain links, heart hooks and cable damascus. I have attached the images of my heart hook, "flux spoons" and cable attempts. The heart hook isnt perfect but im really happy with how the weld came out. The cable was interesting because we did not do the method i usually see. Most of the time i see people weld up the ends of the cable to prevent splitting then they heat the cable and twist it together tighter before welding it flat using the anvil. The way we were taught was to use the u shapped depressions in a swage block and hammer into the swage depression while rotating the bar. It seemed to work pretty well and i am excited to work the piece out now to see what i really have.

- 2 replies

-

- success

- forge welding

-

(and 1 more)

Tagged with:

-

You are totally correct, i was simply referring to his past projects which have primarily been pattern welded blades. I also didnt want to say known high carbon blades because it sounded wrong i mean technically his file could preform better than say a blade from O1.

-

a different style leaf key chain, atleast for me.

Dustin Quade replied to Mark Ling's topic in Member Projects

Those look great, i have been having trouble deciding what to do with the stem of the leaves i have made but this looks like a great option. Thanks for sharing! -

I actually really love this style of knife, both the handle and the rasp or file knives. I know they are usually unknown steel and dont hold up as well as damascus or similar blades but i really just dig the way they look . Congrats on another great knife project.

-

My favorite of the lot is the cubic twist handle rr spike one. I just love cube twists and have always wanted to do one but have yet to make the attempt. All of them loook great though.

-

Very cool pommel idea. Over all it is an incredibly beautiful piece, now lets just hope the kid appreciates fine blades in the future.

-

So happy to see this one completed. Seeing the original renderings of the tiger pommel i was curious to see how it would all come together. Looks amazing great job.

-

As always your work is super impressive.

-

Looks great, did you weld on the smaller branches or actually split and draw them out?

-

That piece is beautiful, i love seeing stuff like this on here. Are the copper circles just small lengths of cut copper pipe?