-

Posts

863 -

Joined

-

Last visited

-

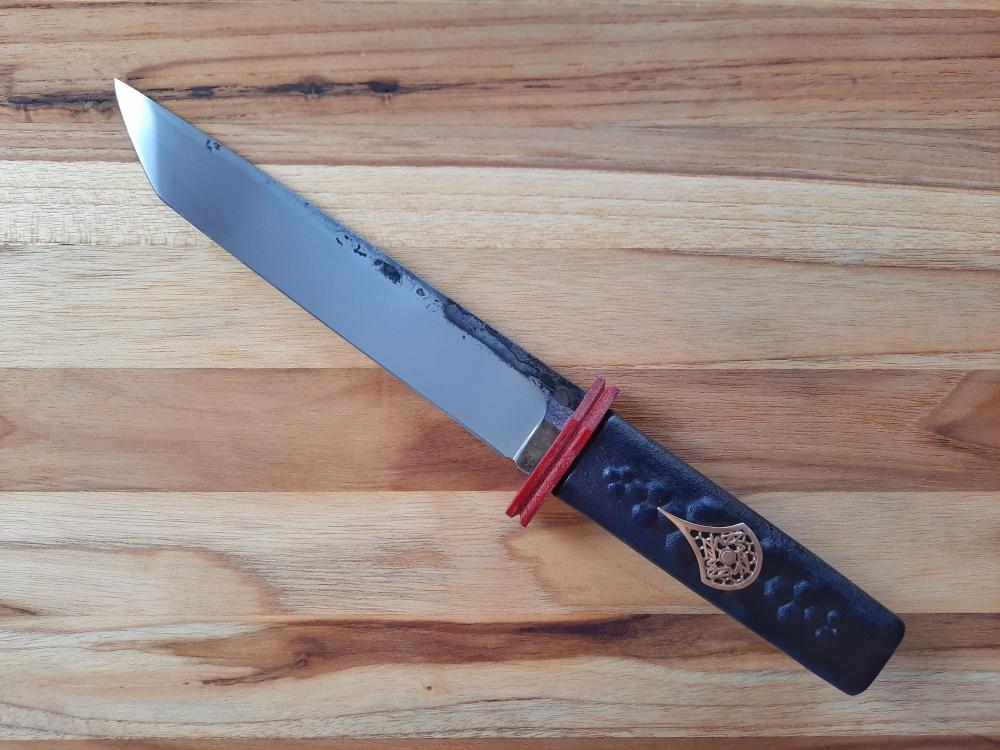

Thanks! yeah, your hand just sinks into the leather handle

-

Sorry I disappeared there for a bit... Covid, amiright? Here's some fun recent work of mine that involve new techniques and materials (to me). The purple-handled slicer has a spacer of material that starts as a 3D printed matrix that I then fill the voids with dyed epoxy. This "gold" filament looks somewhat like amber to me. All the wood is by my shopmate Justin Kirck. I've also been playing with molded leather handles and getting some fun results. Let me know what yall think!

-

With Covid trapping me indoors I now have the opportunity to support the community by offering a way to convert their drawings into PDF, DWG, etc for cutting. Send me a pic of a blade you were considering doing a small run of and I'll use it to make the files vendors will need for their machines. Not sure just how much free time I will have, so just one per person til I get a sense of the volume I am looking at.

-

Thank yall! 24" oal, aprx 2lbs

-

Integral damascus short sword I just finished. 1095 and 15N20 blade with cast bronze handle and samé (stingray skin). The consigner gave me the ashes of a loved one that I mixed with phosphorescent powder and encased within the handle - it should have a faint glow at night.

-

Getting the new shop set up took a long while, and I am now back to churning out some of my own work (instead of my students getting to have all the fun). 1095 and 15n20 twist pattern with bronze guard, reconstone, and stabilized spalted maple. 16" oal, 9.5" blade, 2" at widest. Forged 5160 blade with stabilized dyed burl by @justintheblacksmith

-

Hi everyone! Just wanted to let yall know I'm throwing a little shindig at the new shop and you're invited! Help us celebrate blacksmithing in Brooklyn! Industry City is thrilled to welcome and celebrate the opening of Nazz Forge, a blacksmithing school. Join us on Friday October 4 7pm for live music by Frida Kill in Courtyard 5/6. Light bites will be provided and drinks will be available for purchase. You can pick your poison – the celebration is taking place next to IC’s Brewers & Distillers: Frying Pan Brooklyn, Big aLICe Brewing, Brooklyn Kura (craft sake) and Barrow’s Intense (ginger liquer + full bar). Nazz Forge will provide bladesmith classes, apprenticeship programs, and blade commissions in Industry City Building 6 at 34 34th Street. Each session spans four hours and makes the perfect activity to do alongside a friend, loved one or as a team building exercise with co-workers. Date And Time Fri, October 4, 2019 7:00 PM – 10:00 PM EDT Location Industry City: Courtyard 5/6, 51 35th St, Brooklyn, NY 11232 Hope to see you there, Theo

-

My friend Justin Kirck is on tonight's episode, make sure to check it out

-

It's pretty interesting, they have a lot of bounce because the internal cavities are filled with G-Flex. After a couple really good bashes with a hammer I started to see some gapping between the guard and handle material, but nothing moved. More bashing and I wasn't able to get the guard off but it was wiggling and the handle material destroyed in the process. In the case of the above blade, the burl is going to come apart way before the guard does.

-

Thank you guys, I always appreciate honesty

-

Just got back from another vacation with my wife, so felt the pressure to get something done with the kopis project. I call it a "san mai lazy mosaic", basically skipped a step and didn't properly tile the slices. Kinda looks like camouflage. Only rough ground, gotta reheat and tap the core/edge center.

- 17 replies

-

- olive wood

- cyprus

-

(and 2 more)

Tagged with:

-

First Custom Knife I’ve Ever Sold (pic heavy)

TheoRockNazz replied to C-1ToolSteel's topic in Knife Making

Beautiful work! -

Bit by the bug! Welcome!

-

Wonderfully done! Looks great

-

A fantastic first knife, very well done! You chose one of the more difficult projects in general too; turned out great.