-

Posts

271 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Dustin Quade

-

LolYea when i was trying to figure out how to mount it initially i was hoping to find a stump or something but never did and i couldnt wait to start working so i built this as stable as possible. i tried to support it on the ends and along the edge to shore up the main piece as much as possible. the spikes used to make alot of noise but over time they kinda settled into a lump that doesnt move much any more

-

Thanks, heat treating was actually not to hard i heated the blade through until just over non magnetic and quenched into canola oil. I cant say what brand it was it was given to me by my father in law who had it from his farm as a kid. I used my drill press to make a bit of a hollow into the bottom of the hole where the tang goes so it will make like a well then the tang near the bottom i filed a small groove so as the glue hardens it will kinda lock into that groove. I used gorilla glue .

- 2 replies

-

- deer antler

- farrier rasp

-

(and 2 more)

Tagged with:

-

I have made a couple of knives from a blacksmithing class but these are the first i have made at home without a teachers guidance. Never done any with a deer antler handle or a guard. Pretty happy with how they came out.

- 2 replies

-

- deer antler

- farrier rasp

-

(and 2 more)

Tagged with:

-

I actually hadn't thought to do that but yea i might just make a smaller knife from the blade portion if the steel test goes well.

- 11 replies

-

Alright il give it a shot. I have some O1 steel kicking around.

- 11 replies

-

Sure here is a link where i posted some pictures of them.I spark tested some pieces and they spark high carbon. other than a spark test how can you tell good from bad? http://www.iforgeiron.com/topic/44535-damascus-pattern-identification/

- 11 replies

-

-

Thanks for the tips i will certainly look into GFLEX for my future projects. For these i opted to use gorilla glue since i had some kicking around.

-

- 11 replies

-

Quick ball pien hawk

Dustin Quade replied to navasky's topic in Axes, Hatchets, Hawks, Choppers, etc

Wicked Job, just another project i would like to try in future. -

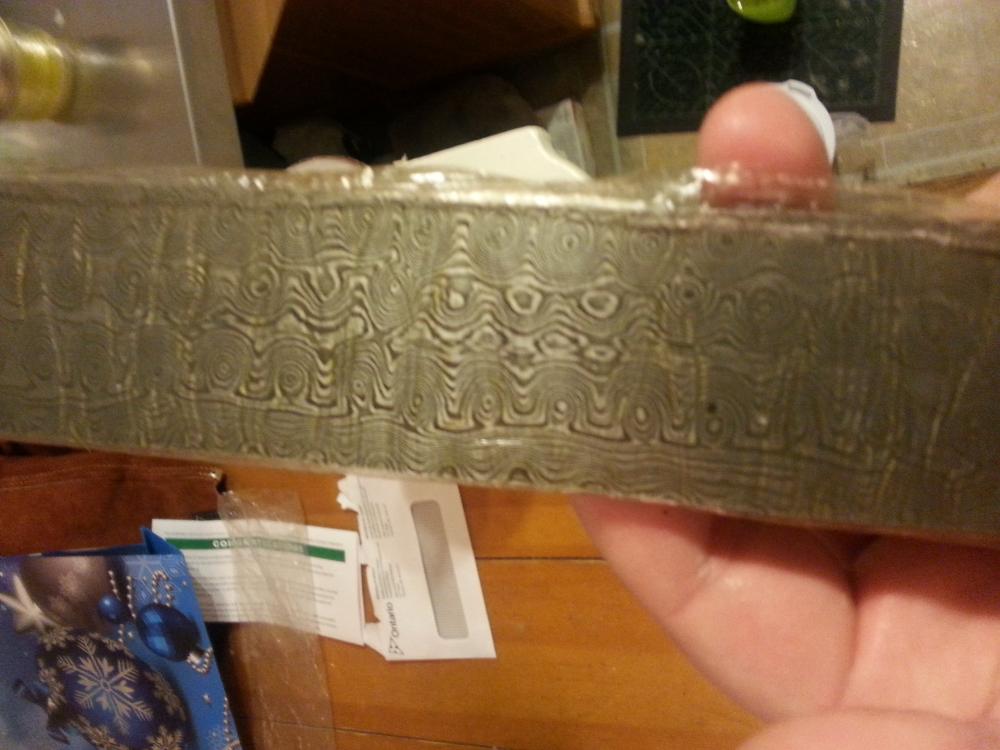

So i got my hands on some damascus steel last week and wanted to know how to tell what type of pattern they are. There were 5 patterns in the batch i got. I have attached images for reference.They are made of 1095 and 15N20.

- 9 replies

-

- damascus

- damascus pattern

-

(and 1 more)

Tagged with:

-

I only have a pic of the knife when i got it. I will take a picture of the knife with the handle removed tonight. In the picture attached the handle would spin around the tang from the black section second from the guard and the first black section from the bottom.

- 11 replies

-

So last week i met up with a knife maker who had decided to get out of the field. He sold me some damascus billets and as i was leaving he asked me if i could replace a handle on a knife, i told him i was pretty sure i could so he went inside and brought out a beautiful damascus knife with a guard and butt cap also damascus. The handle material was stacked sections of wood and brass but the glue had come loose on the pieces so it was all spinning around the tang and was essentially useless. So i took it home and took the handle off but now that i see the tang it is insanely thin, like the width of a pipe cleaner. Looking at it i just feel like it would never stand up to use as a knife for anything but show. So i thought about cutting the whole thing off and welding on a new tang entirely. Any thoughts on this? I guess pros and cons really. Like would my weld make for a weaker tang than just leaving it in its current state?

- 11 replies

-

That ring is an awesome idea. I just got my hands on a pile of damascus i think i will need to look into how to make one of those for myself. Thanks for the idea.

-

Thanks for the help. I didnt know you had to mix the stuff seperate before applying, the package just said to squeeze the stuff out. I will try to clean them up tonight and give it another go. Il post some picks when i get it all sorted out. As for brand i think it was made by 3M.

-

So Christmas is coming up and I wanted to make a knife for my Father and my Father in law. I forged out a couple of knives from an old farriers rasp, made a brass guard and used a couple of old antlers for the handles. Everything is fitted how I want so I put some two part epoxy into the antler and around the edge to secure the guard to the handle. The packaging says that the stuff sets in 5 minutes and cures in 30 but I let them sit over night (so like 7 hours) and the epoxy is still runny. Is this normal and the packaging is just bs or should I take it all apart and try again with another type of glue?