Bo T

Members-

Posts

180 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Washington state

-

Interests

I have recently become interested in blacksmithing and knife making as hobbies.

Recent Profile Visitors

-

How much would a slightly more outlandish commission typically cost?

Bo T replied to ParagonBlade's topic in Swordsmithing

I remember the sword quite well. Looked similar to a Roman short sword but a hand longer. About 4" wide with a deep fuller with a series of holes inside. About 3 pounds. I think some farmers found some of our artifacts and modeled the Roman short sword from them. But, due to their exceedingly short life spans simplified it so they could use them effectively. No magic. Just a joint that allowed the sword to come apart at the middle seam. But the tribesmen who we conquered believed it was magic. Our metal was cast, then finished by the best crafts people on this planet. It was said that it took many decades to master the sword. There were holes in the hilt, that gave a light hold when wielding the half swords without fear of them slipping from ones grip. The pommels attached with a joint not much different from that used in folding ladders. And, the half swords could be locked pommel to pommel at different angles. In a battle one was used as a grapple to scale a villages wall. Those were different times. Those of us left, dispersed to different parts of the world when our city sank into the ocean. These histories have been told but I read that the ancient writing has not been solved. Good luck on having one made. A captured sword would trade for many times its weight in precious stones and metals. -

I might be imagining it, but there seems to be a slight 'quench line' above the edge? Especially towards the tip?

-

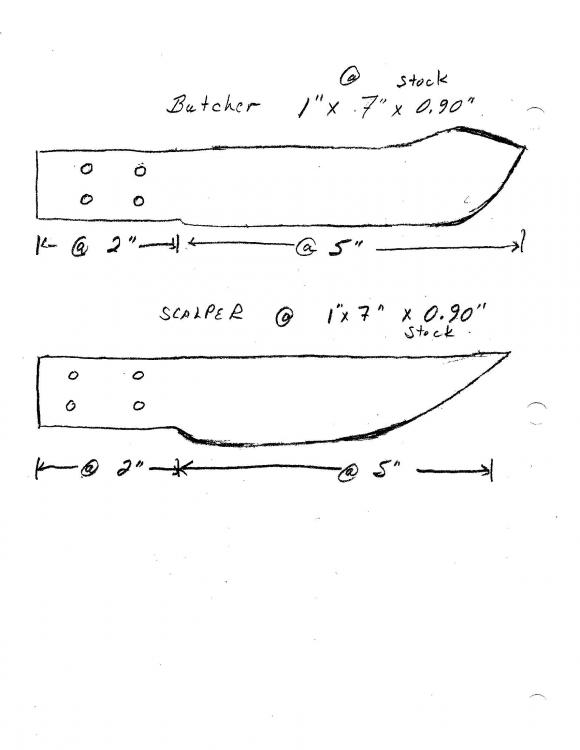

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

Frosty, Friends and I have done a little fishing for Laotian Cutthroat in Lenore Lake, I think just north of Moses lake. We also did some hunting in the scablands. A number of little fishing lakes along I-90. Oh, and I'm one of those guys that needs a good topo and compass if very far off of the trail. I'm actually west of Spokane. Anyway, you think some inexpensive hickory for the handles? -

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

Frosty, I'm just east of Spokane. The sketch is for the blade only. And I'm looking at a half tang knife. A lot of the fur trade knives seem to have longer blades, but there are shorter ones also. Now these are rough sketches and the tang might stretch out more after punching the holes and flatting. I'm thinking a shorter blade will be easier for a beginner than a longer blade. -

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

Darn. My ruddy cheeks are some what redder. Steve is right-0.090". -

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

Regarding Albert Craven-blade forger. I watched the documentary on him again. In it he states he could do 2 gross of small pieces in a day. Which at that time would have been 336 blades (watch the documentary). -

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

-

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

Another idea on the single bevel that the IP used was that it worked well for the skinning of game. Thanks for the link to the Archaeological Metallurgy site. I'll send them an e-mail. I'll sketch out some profiles and post them later. -

The Entire History Of Steel. By Jonathan Schifman

Bo T replied to 671jungle's topic in Historical Ironwork

I will go looking for Aston and Storey. If wrought iron can have more than 0.25% carbon then that would lead to the possibility of quench hardening some wrought iron. -

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

From some of the archaeological papers I have read, many of the fur trade era knives and axes were identified as iron. And also as having no evidence of a steel bit. This, of course, indicates the blades were made of wrought iron. Also, some information from early Britton labels knife artifacts as iron while later knife artifacts are labeled as steel. I am thinking that due to cost, knives for the lower class and for trade would, at least early on, be made from wrought iron. In the Americas, as the indigenous population became more sophisticated, I'm guessing bitted knives and axes would be introduced, followed by steel knives in the later part of the 19th century. I think early scythes and sickles from Europe were probably wrought iron as, I believe the edge was work hardened. Which is moot as double/triple refined wrought iron is as scarce as hens teeth and as expensive as the golden egg. I'll probably make due with some 1084. If indeed many of these trade knives were made from wrought iron, the thin strips of the correct width would probably have greater availability due to demand from the blacksmith community. -

Fur trade era butcher and scalper (16th - early 19th century)

Bo T replied to Bo T's topic in Historical Blades

I have not corresponded with anyone regarding the forging of blades in Sheffield. I have watched the documentary on Albert Cravens. So, my understanding is, there were 3 trades involved in the manufacture of knives. These were forger, grinder, and cutler. Knives for the fur trade were likely of low quality and forged as quickly as possible. According to Cravens, a gross of small blades, for pocket knives were possible on a per day basis. Because the forgers were paid per blade, starting with metal of the correct thickness and width would be needed. Cutting that metal to the best starting profile, allowing the smith to complete the blade in the fewest number of heats and the fewest hammer blows, of some importance. I have only forged a few blades so I don't have any experience to speak of. I imagine that a rectangular piece of steel would work for a butcher. As the tip of the blade is formed on the edge, the metal would move across the top to form the distinctive hump above and behind the tip? For a scalper, perhaps a diagonal cut forward down to the tip, to allow for the relatively flat back? But I am not at all sure of this. I am contemplating blades where the width of the starting steel is about the same as the height of the handle from top to bottom. About a 4-7" blade with a 2" tang. -

The Entire History Of Steel. By Jonathan Schifman

Bo T replied to 671jungle's topic in Historical Ironwork

Dang. I have not considered wrought iron and cast iron as subsets of steel. This helps. -

I am interested in learning about the methods the forgers in Sheffield and France would have used to forge these blades. For example; thickness and width of the blanks, the initial shape of the blank, and the hammering pattern to form the final shape. I am thinking of the half tang 4 pin blades Thanks in advance, Bo.

-

The Entire History Of Steel. By Jonathan Schifman

Bo T replied to 671jungle's topic in Historical Ironwork

The highest carbon content for wrought iron that I have read (excepting this article) is 0.25%. So I think that the assessment on a poorly written article is correct. Perhaps the author plagerized an earlier article and published. One question that keeps coming up is "How do you distinguish between wrought iron and steel?" I think (not certain), that it has to do with the layers of silica within the wrought iron structure. Where as the steel would be more uniform with much less silica in it? -

The dry ice cold treatment is sometimes used to help convert unconverted austenite(RA) to martensite. I am not sure how much RA would be left in quenched S7? I am not sure how much help cryogenic (liquid nitrogen) treatment would help with S7 either. I have some reading lying around somewhere, but the scientists doing that work are probably +/- 10 F on their temperature control. Not necessarily applicable to the present situation. Note: mix your dry ice with acetone. That should get the temperature down to @ -100 C.