-

Posts

6,051 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BIGGUNDOCTOR

-

BillyBones, why do you say 12L14 is not usable? Because of the little bit of lead it has in it? Plenty of items can be forged from it.

-

I have a similar forge , and it has been used outside since the late 70's, never lined it. Indoors it would be fine, but outside the lining can hold moisture, and rot the pan.

-

Fisher anvil questions

BIGGUNDOCTOR replied to Bo Diddley's topic in Anvils, Swage Blocks, and Mandrels

Bo, not all anvils have a horn. It depends on what they are used for. As mentioned above, these were used to tune circular saw blades so they ran straight and true. This was done on a COLD blade, not one heated in a forge. No need for a horn when all you work on is flat saw blades. Look up sawyer's anvil for more info. -

What did you do in the shop today?

BIGGUNDOCTOR replied to Mark Ling's topic in Blacksmithing, General Discussion

"Don't believe everything you read on the Internet" Abraham Lincoln. -

Some steel suppliers like Ryerson sold textured and rigidized sheets.

-

How do you develop a useful scrap pile ?

BIGGUNDOCTOR replied to Glenn's topic in Blacksmithing, General Discussion

Anvil, that is like the surprise my uncle in Florida got when he bought a "box" of chain sight unseen at a govt surplus auction. Forgot how much he paid, but it was well under $100. The box turned out to be a RR box car.................. Luckily he had some time for removal, and was able to sell it off right off the car. He ran an ad, and moved it as fast has he could, and did pretty well in the end. Glenn, that is how I built my smithy walls. Stacked 55 gallon drums 4 high by 4to5 wide staggered. I now have free standing walls 8'x10' that hold material , and tools. They have withstood 50 mile an hour winds, and I can move them with my forklift if need be. -

Chimaera, many mower blades are a special boron alloy that takes a very specialized heat treatment to harden. Experiment first before investing a lot of time. Well I just bought a Scotchman 6509 ironworker at an auction. Paid more than originally set out to, but still did pretty good. Watching videos of them the ram goes up and down pretty fast, and at 65 ton capacity it could possibly be used for smithing. Good thing I also won two box trucks, as I can use one to bring it home I'll post pictures once I get it home.

-

That is a Lunette eye for a trailer hitch. $84 new on the big river site. It gets bolted into the channel on the trailer tongue, making it adjustable for height.

-

JHCC, there are anti-fog coatings for glass that are silicone based.

-

I would say the Rigid for these reasons. Bigger jaw opening comes in handy more often than not.. The bigger gap under the jaws comes in VERY handy. Ran into this problem at work recently where I couldn't clamp a part well due to the Wilton having a small gap. The jaws would not close on the part before the part's body was hitting under the jaws. How often do you replace jaws....not often. How often do you have to tighten replaceable jaws...a few times. If you need soft jaws it is quicker to make ones that drop over the standard jaws. And you can make them thicker because the jaws open wider. As for the enclosed screw vs covered. I have yet to see a vise screw worn out from dust in the shop, and I have some old shop vises. The screw is never fully exposed, and covered on 3 sides. Grit would have to go under the rear section, then up to get stuck on the screw. Both are good makes, but I like the Rigid features between these two.

-

Machinist files are a higher grade of steel than rasps. As Nicholson's materials guy put it "Wood and hooves are not as hard as steel" He said that treating the machinist files like W1 for heat treating would be a good path, as he would not give me the exact alloy they have used for the last 46 plus years he has been there.

-

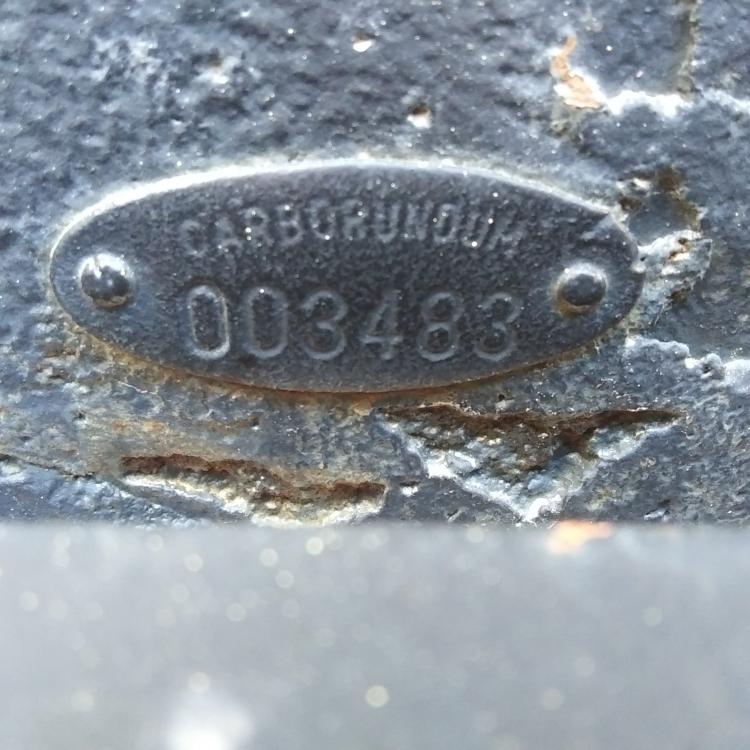

A friend's Sawyer anvil

BIGGUNDOCTOR replied to BIGGUNDOCTOR's topic in Anvils, Swage Blocks, and Mandrels

No, I have plenty of anvils. I was just sharing it with the group. I like the Carborundum inventory tag myself. I have a 150# Vulcan with a school district tag still on it. My main anvil is a 260# Fisher that my Dad bought in Lincoln CA back around 1977. -

Welcome from Southern NV. I was talking with a guy about a 52 Willys truck in Las Cruces.

-

Steve, glad to hear you are picking up some work. I have a few friends who work in the casinos, convention, or entertainment industries, and they are wondering when they will be working again. I lucked out, and got a job 2 years ago in the food industry. We are deemed essential, and never let up on production. One of our plants in Illinois has been hit hard with cases, and have lines down due to a labor shortage. Because if that we are picking up the slack at our plant in Nevada. Yesterday was my first day off in 111 days. Uncle Sam appreciates my extra hours.......

-

I was at a friend's house, and took some pictures of a sawyer that was given to him along with some other anvils from his friend's estate. I gave it a good looking over, but did not see any marks of any kind. If there are some, they may be under the angle iron holding it down. It is a fairly heavy one, I would say at least 200# to possibly 250# going by dimensions and steel being 490# per cubic foot.

-

Welcome from southern NV

-

What did you do in the shop today?

BIGGUNDOCTOR replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes, but you need the base wide enough to be stable and safe to use. -

Rasps are generally not the same alloy as a machinist file since wood and hooves are not nearly as hard as steel is. I talked with the metals guy at Nicholson file, and although he would not give me the exact alloy they used, he said that treating a machinist file like W1 for heat treating was a good bet. He said their machinist files are a higher grade of steel than the wood files and rasps due to the above statement.

-

Need help selecting an anvil

BIGGUNDOCTOR replied to Michael_Tricam's topic in Anvils, Swage Blocks, and Mandrels

You can get an Anvil Brand Legend 120# anvil for $715, and JHM makes some good anvils. I have one of their 125# Journeyman anvils that I got from a retired farrier. It is kind of a cross between a farrier pattern, and a smithing pattern in my eyes. I loaned it to a friend who used it to make "Damascus" billets for knives, and he remarked that it was a good anvil to work on. They are cast ductile iron, and the one I have still looks new. As for size, everything I have done so far could have been done on the JHM easily, but my main anvil is a 260# Fisher. Why? A few reasons, but namely it was the one my Dad and I started with. It is also very quiet to work on. My 306# Soderfors can be muted, and it is an excellent anvil that I had in my old business, but the memories with the Fisher put it on top for now. I understand the trepidation with the big expense. The best rule of thumb for that is , can you comfortably afford the purchase? If you have to choose what flavor Top Ramen you need to eat for the next year, or two to buy it, don't. Look through the improvised anvil thread. Depending on where you live you could probably be smithing by the end of the week on one that may have been free for the hauling. A "REAL" anvil does not have to have a horn, nor a heel to work. All it needs to be is sufficient mass to back up the hammer blows, and be harder than yellow hot steel. An improvised anvil, a JABOD forge, and a garage sale hammer will start you down the path of smithing for the cost of a tank of gas. -

Hay budden value old rough.

BIGGUNDOCTOR replied to Popa's topic in Anvils, Swage Blocks, and Mandrels

Missing the top plate, so pretty much just a hardy hole and a horn. This falls under, whatever someone offers above scrap rate. -

What did you do in the shop today?

BIGGUNDOCTOR replied to Mark Ling's topic in Blacksmithing, General Discussion

The then new Vdara hotel in Las Vegas got the Death Ray knickname the first summer. -

Borrow an oxy acet torch.

-

kettlebell homemade with recycled material tips

BIGGUNDOCTOR replied to angiolino's topic in Problem Solving

Bowling balls come in weights up to 16# -

show us your letter openers

BIGGUNDOCTOR replied to ausfire's topic in Blacksmithing, General Discussion

Red Shed Forge, I would hit them with a belt sander to help smooth them out. A regular wood belt sander works fine with emery belts for projects like this. Or hit them with a file.