Pat Masterson

Members-

Posts

244 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Morganville NJ

Recent Profile Visitors

-

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Wow Mothman - really nice cooking pot. The pot itself especially. So I was able to build this coal forge entirely from scrap except for the fire pot. And blower obviously lol. Took the better part of a weekend. Really happy with the way it came out but I struggled with my first fire yesterday. The fire pot is pretty large. It was smoking like crazy - I’m thinking I started off with too much coal…? It took quite a while but I did eventually get a good fire going but it was too far down in the fire pot. Seems like I’d have to use a very large amount of coal to have it built up so my work piece could be parallel with the top and be in correct spot of the fire. Questions: 1. How long does it usually take you guys to get a good useful fire going? 2. Should there be very little smoke coming from the fire after it gets going? 3. I mentioned the large size of the fire pot..I was thinking I could put four bricks in the bottom, one up against each side, to kind of hold the coal to build my fire higher up without using so much coal - thoughts? -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

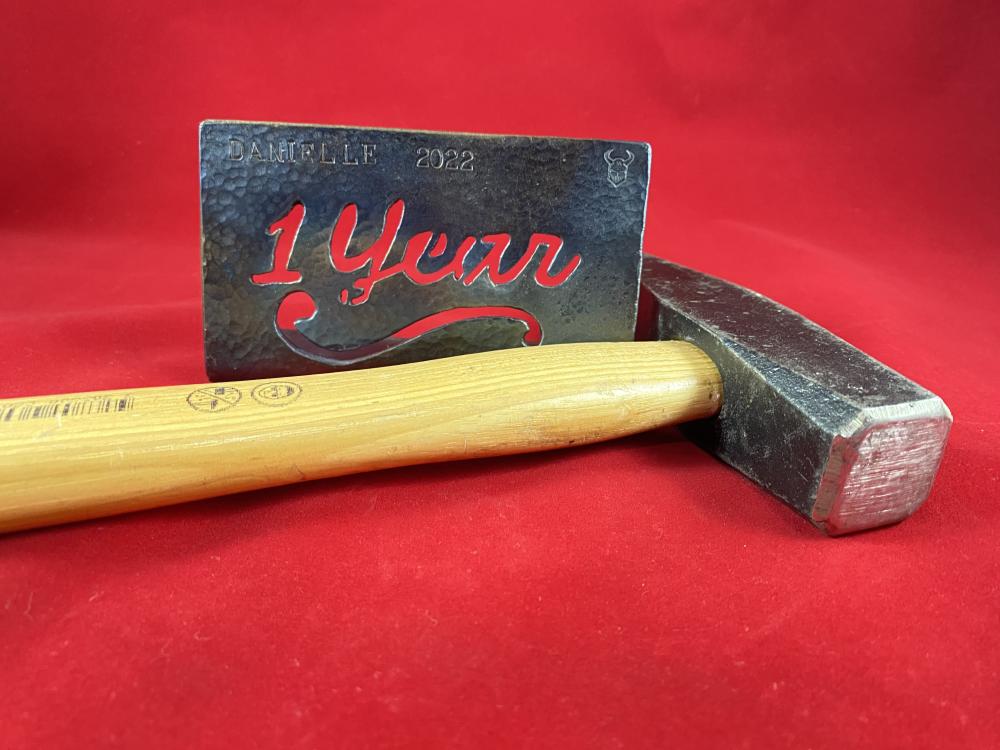

Wishing you good health and happiness Thomas - hang in there. Goods, that hammer is a beauty. Definitely a dream of mine to have one someday. Also got another little gas Forge off Amazon. It was so cheap I couldn’t resist and it has a larger working area than my current one. I coated the kaowool with Greenpatch 421 though - really good option if anyone needs to insulate a new or repair a damaged forge lining. Once I wet down the kaowool a little it spread on very easy. It comes premixed which is nice. I wanted to use most of it to line the new forge but my old one needed a little love so I just put a thin layer over the old refractory and man does this stuff help retain the heat. Some of my latest stuff below. Really happy with the one year plaque - I love the way temper colors come out on plate steel. They always seem to be more colorful than bar stock. Maybe just bc it’s more surface area. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

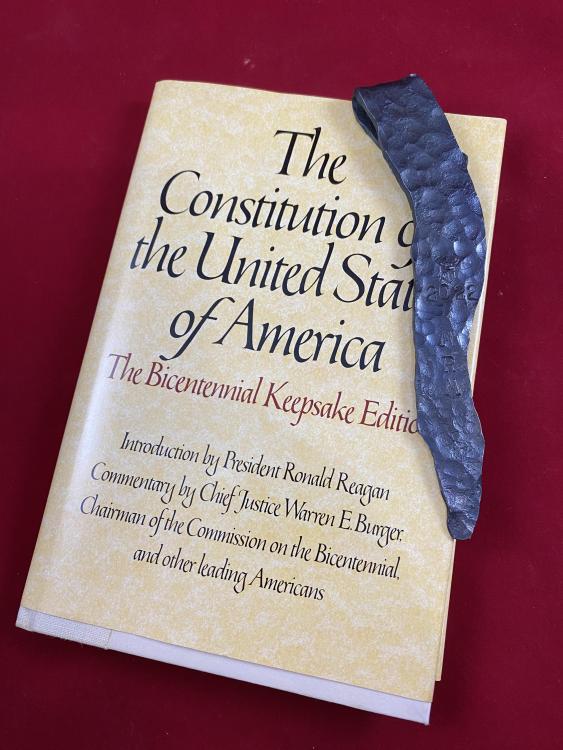

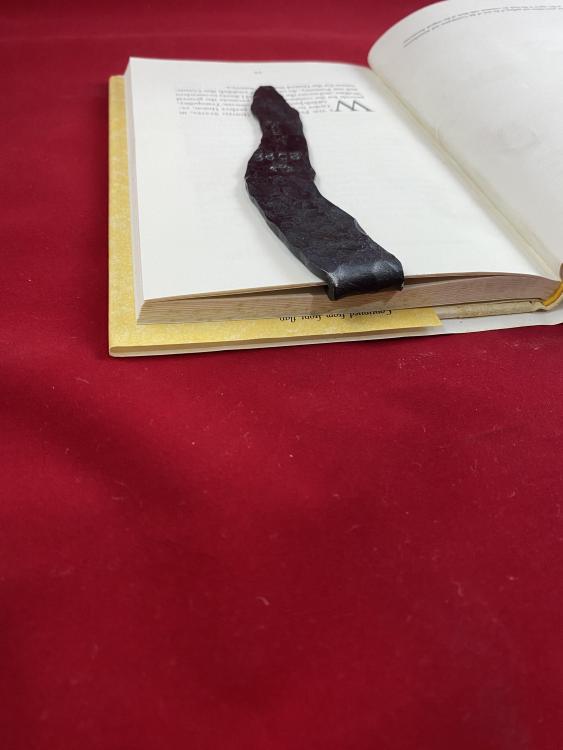

Yes - I have a new appreciation for simply being above ground these days lol. Thanks for the kind words though. Thanks Shainarue. I was also worried about them being too thick. I wanted to use 1/8x1 but I only had 1/4x1 on hand so I flattened the material out quite a bit, then a bit more putting the texture in. They’re probably at about 1/8” for each side now so about 1/4” total. I’m considering going back and maybe taking 1mm or so off with the belt grinder. I purposely made the curves in them go towards the end of the book rather than the spine which helped with allowing the book to close enough. I like the magnetic idea - if the bookmark itself was kind of grabbing on to the pages from magnetism on each side you wouldn’t have to worry about it ever sliding out. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

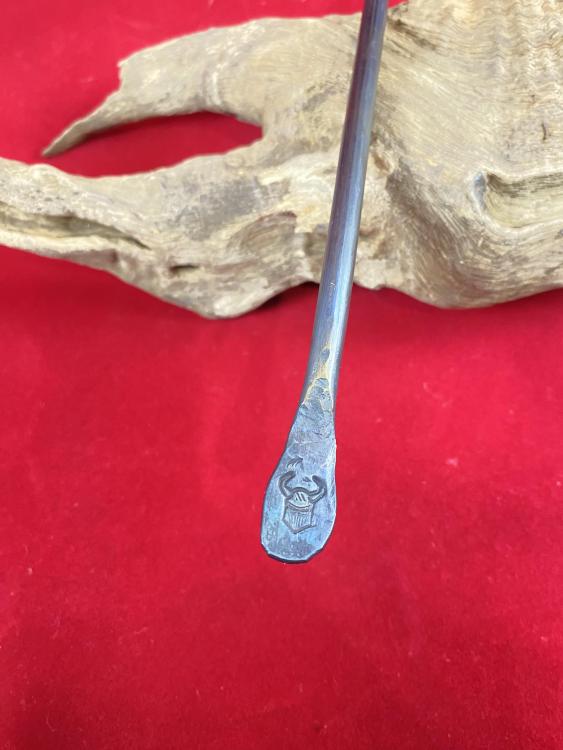

Spent some time in the hospital recently…feels good to finally get the forge going again. One plus is I have a months worth of posts to look through. Nice Calla Lily Chad. I just made one as a Christmas present - really happy with the way it came out. Made a couple book marks too. I love stamping in letters and dates but I suck at getting them to line up lol. I think I’m going to try to make a little jig that will keep the spacing correct. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

I was thinking about getting that lottery ticket…then we had two family tragedies inside of four days - my 70 year old aunt which was totally unexpected- complications during a surgery. And my 95 year grandmother on the day of my aunts funeral two days ago. This one was at least somewhat expected as we knew she was on her way out but doesn’t make it any easier. Anyway - not being at work and needing to keep my mind occupied I got some stuff done. These commemorative pieces for my two cousins. And I realized that to get to the next level I really need to be able to use a coal forge. Getting the meridian straight in line after the bend for this globe for example. So difficult with what’s basically a coffee can forge and then all the other benefits (localized heating yada yada) Today I’ll try my first coal fire after making the saddest example of a coal dump you’ll ever see lol. But I don’t care for now. I think it will some what work and I can finally try my hand at coal. I keep a large first aid kit in the truck and small one in the passenger door - ya never know. IMG_3663.MOV -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks for the help and compliments guys. Unfortunately I always seem to have a case of major beginners luck. From forge welded basket twists right thru to basically everything I’ve done and then tried to duplicate besides easy stuff like flowers - If you look closely the twist and bend is far from perfect - I’ve also realized things are much different when you have zero time constraints and are simply doing a project for fun which is what the original globe was vs a paying customer who’s waiting for their purchase. On this one I did do a much better job on the 1/2” stock base and then welding it where the ends came together than I did on the first one…but I’ve saved the toughest part for last. I went 5 inches long - I’ve kept notes this time though so at least the meridian is a mistake/test I won’t have to deal with again. Center punch mark is so I can know where they were welded together. Might as well weld the meridian right at that spot again to hide any signs. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey guys. Getting ready to do the meridian on this globe and was just curious…now obviously it depends on how tight your twists are but if you take a 30” bar for example and put an even twist down the entire length I would imagine that bar is going to be shorter after the twisting. Is there any kind of know formula to calculate the loss of length? Again I’m assuming there’s not because of the variance in any given twist tightness but basically, using a wire, I measured that the meridian length is 26” from pole to pole with an even amount of space between the meridian and the sphere itself but right before I went to twist it this thought hit me so I held off. If there is no possible way of figuring out how much the twist is going to affect it then obviously I’ll just overshoot by a few inches, twist, bend it and then cut the excess off but I figured it was worth at least asking. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Horseshoe crosses are really something Dave. Nice work. Thanks Shainarue -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Wow Alexandr - unbelievable as always! -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

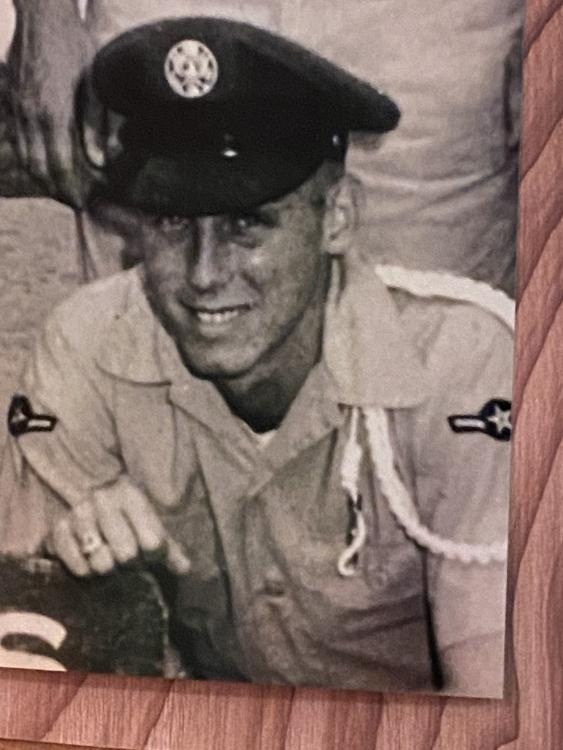

Nice cross Das. I got some work done on this customer globe. Made a real bonehead mistake lol. I got all the continent’s epoxied on but I kept staring at it knowing something was off but couldn’t figure out what - then it hit me: I only did half the amount of spokes I was supposed to, making this one look very open and I was super angry (original globe pic for reference). Starting over would mean months because of my work schedule.Taking the continents off, welding in the missing spokes and then reattaching the continents would mean at least two more weekends. (I desperately need to learn to be able to cleanly weld the continents on rather than epoxy - I think that’s going to mean a tig welder. The cheap flux core I have plus my nonexistent skills mean the welds are either so ugly I can’t sell it like that or I blow holes right through the thin continents. Maybe I can learn to braze them on). Anyway I called the customer and just told her what had happened and offered another item, discount or some kind of other addition to the globe. She asked if I could make a steel version of her late husbands Air Force rank from this picture and attach it to the globe and we could call it even so I said I’d give it a shot. I actually think it came out pretty cool looking. I’ve got the base made so now it’s just making the meridian and putting it all together. Also I bought one of those photo light box things to improve my Etsy pics but I really want one of these driftwood looking prop things I see in a lot of pics from knife makers. Does anyone know where something like this could be bought instead of me running around the beach trying to get lucky lol? I can’t find anything like them for sale online. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

I also have to remember to have the original out there with me for reference for future sets so the twists in the shafts come out much more similar. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Frosty. The arm brace is a pretty good idea. And I appreciate the compliment on the poker but if you look at the difference in the two basket twist handles, one is clearly nicer and more graceful so I just wouldn’t have sold it to an Etsy customer. -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

I had this attempt at a fire poker for an Etsy customer but there was no way I could bring myself to charge him for it - it was just too ugly. But I made a poker for my step dad and he loved it - more so because he has this really large fancy set of tools that are just way too heavy. He has a condition that makes his grip weak but these things even feel ridiculously heavy to me. It happened to be his birthday so I decided to tweak the handle as best I could and take my first shot at a shovel (first time riveting as well). It’s not pretty but it will certainly scoop ash out of the fireplace and is about half the weight of the other so it’ll go to good use. I really have to figure out how to do my stamping in a straight line though lol. Such a great feature to offer but it’s hard to make it look good. I also finally tried out this photo light box to help my Etsy pictures look more appealing. Took a lot of playing around with because I know zero about photography and of course it did not come with instructions but you can already see the difference in quality in the shot with the red background compared to my originals. And I’m making some good progress on this second globe. Made an incredibly dumb move and only used half the amount of spokes as the original. I spoke to customer and offered some kind of custom feature instead of refunding or trying to add in the missing spokes with some of the continents already attached. Her late husband was in the air force and she had a picture of one his ranks when he first got in. So we agreed I would make a replica of that and have that mounted on the globe as well which I think is pretty cool. -

I have used Iron mountain and plain old 20 mule team - they definitely react differently and I think each has its own situations where one will work better than the other. Found this beast in the middle of an intersection last week. I wasnt sure what it was so after I got about a half mile away my curiosity got the best of me and I turned back. Don’t know anyone that can use is it is so it will be canabalized for the steel.

-

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Ya know as embarrassed as I am to say it that never crossed my mind. I literally used a bending fork hardy and my hands and then hammer and anvil horn.