-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by RogerrogerD

-

125 year old Alldays and Onions bellows restoration

RogerrogerD replied to RogerrogerD's topic in Bellows, Blowers

Tim, I’ll weigh one tomorrow and post here. Mine came with just one ball shaped weight, probably cast iron, and i bought a mild steel ball and welded on a loop to match. I don’t suppose it matters what shape it is. I have seen these operating with just one weight on one side, and frankly I haven't worked out the physics. -

No Peter Wright markings on it, which is a pity, but hey I bought it to use. Out looking for a suitable tree stump/log to mount it on to. I have a couple of post vices, but a tough old bench vice like this will find a use in my new forge, with the build starting next week...

-

I went to pick up this late 1800s wood lathe, bought for £50, and the guy asked if I was interested in his old vise/vice. “Let’s have a look” I said.... It’s a Peter Wright style bench vice, 6” jaws, I think original leather washers. In need of restoration but quite a beast. £40. Yes please I said.

-

Little and Large. Got given this old jewellers anvil and vice today by a passing carpenter who found it in a waste bin. I’ll clean it up, screw it to a base and fit it in the hardy hole on my big JB.

-

Not a shop, but a key part of a shop. Decided I was fed up with chasing down rivets, nuts, bolts and washers spread across various drawers, boxes, bags, jars and too many of those fiddly small plastic draw things. So I picked up a bunch of industrial “pigeon hole” shelving as salvage and giving them a spruce up.

-

What did you do in the shop today?

RogerrogerD replied to Mark Ling's topic in Blacksmithing, General Discussion

My first ever blade, a kiridashi, and a prototype. Not yet sharpened but happy with my first attempt fastening wooden handle scales. I need to take more care with getting the epoxy to the edges, but other than that it’ll do. I’m using some Persian Ironwood . Sounds exotic but I have three small trees in my garden and took a few limbs off to dry a few years ago. It’s hard as bone, and has an interesting mottled effect to it. First coat of linseed oil applied. -

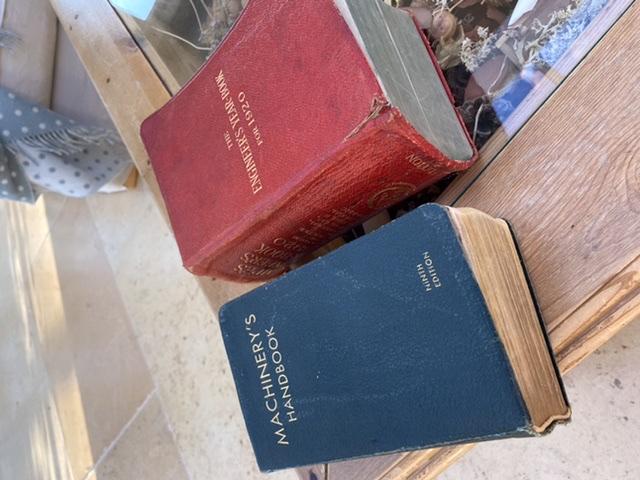

Couple of lovely old workshop bibles. Machinery’s Handbook from 1934 and Kempe’s Engineering Handbook from 1920.

-

As a barely competent smith and a barely competent welder, I find a good looking rivet easier to achieve in many circumstances than a good looking weld. There is something more innately appealing to me about a rivet than a weld too. But I need to improve both my skills. But I’ll usually drill a hole rather than punch a hole, accepting that’s not always the best solution, just habit and because it reflects my skills, or rather lack of them. I’d like to be good at forge welding, I’d like to be good at Mig and Tig, and I’d like to be a better smith, then make the choice on what looks best rather than make the choice on what’s easier to achieve. A good excuse, maybe the best excuse, to get back to the shop tomorrow and practice some more, learn some more and head in the direction of more skill all round.

-

My view is that most bench vices are cast iron. Hitting one with a hammer is actually somewhat dangerous because cast iron is usually brittle. A bench vice holds an item firm, and that’s it. A post vice/ leg vice is actually designed to both hold something firm , and also to take heavy blows. They are totally different tools really. You wouldnt use a cast Iron chisel or a cast iron hammer. Same goes with a cast iron vice for anything other than light work.

-

I’d “retire” it from regular forging, and use it, if you have the space, simply to hold hardy tools, or a guillotine tool held in the hardy, or just use it as an extra horn, or the “table” bit behind the horn which is meant to be soft for cutting etc. If you have the luxury of space next to another better faced anvil, then this grandfather still has some pragmatic uses. I have a second anvil, unsuitable for forging on, which has a smithin’ magician almost permanently mounted on it, which makes life a little simpler.

-

I reckon you’ll quickly find the spots on this large anvil that will do the trick for whatever forging you are doing. It’s a nice big anvil and one of the things about big anvils is you have that wide choice of particular spots that work for you. Within a short while you’ll be doing that without consciously thinking about it. I’m lucky, I have a big anvil too, and it has even more chips on the edges, but I don't even notice them any more, just ignore them. Looks like this has been repaired, maybe not well, on one side, so just spin it and use the other side. I wouldn't worry at all about the dings on the face.

-

125 year old Alldays and Onions bellows restoration

RogerrogerD replied to RogerrogerD's topic in Bellows, Blowers

I love it more every day. It sighs and whispers to me as I work it, sometimes with a happy grunt as it clears its throat. Wooshhhhh. Click click clack whoooshhhhh click click clack. The forge gently exhales in synch. Harrrrr. Harrrrr. Who needs music? Mind you, my very amateur hammering of steel on the anvil is like a kid playing a piano for the first time. That’s not musical yet... -

For a “used” anvil it looks pretty good. I have a JB, not as clean edged as that though. Ball bearing bounce is 90% + though...

-

Here’s mine, made from an alder trunk. Bolted it to the floor, and attached two Leg vices, and and a small vice mounted vertically.

-

Newbie, Gasser, Forge Welding, Sweat, Frustration

RogerrogerD replied to wrickm's topic in Blacksmithing, General Discussion

If you are new to blacksmithing, as you say, maybe develop some other blacksmithing skills first. In my experience forge welding isn’t a “basic” skill, it’s a “tricky” one. I’ve been been blacksmithing for about 18 months and forge welding can be very hard. I was making some chain links a couple of months ago and one or two pretty much looked like yours... it’s fine, it’s learning but you will get less frustrated and more confident developing other skills first. As you do other things you’ll learn about gauging temperature, about what you can get away with and what you can’t. All useful stuff when you do get around to forge welding down the line -

What works best to free rusted parts

RogerrogerD replied to Roy56's topic in Gunsmithing, Muskets, Flintlocks etc

Heat. -

125 year old Alldays and Onions bellows restoration

RogerrogerD replied to RogerrogerD's topic in Bellows, Blowers

I think it worked for its keep for a few years but for the last 30 years it was at first a decorative feature in this guy’s hallway after he came across it in a junk store. He had done some restoration then including ouling the leather. His wife told him to move it out 20 years ago and since then he had it under a blanket in a garage. The leather soaks up any neatsfoot oil I put on it. I guess i’ll Keep reapplying . -

I picked up a lovely set of Alldays and Onions bellows on ebay and have restored them, and put them to use. Maybe 125 years old I reckon. Triple chamber, works smoothly. Leather is original, just treated with “neatsfoot” oil. A little woodworm, now treated. The top board is warped, but doesn’t affect the function and adds to its charm. At first I think one of the leather flap valves was sticking, I think, and the top chamber wasn't expanding, and I was dreading having to unpin the leather bellows but as I used it, it began working and now is working just fine. I have hooked it up to my modern side blower forge by cutting a hole in the back so I can run electric, manual either or. One of the cast iron weights was missing, but have replaced with a mild steel ball, almost as good. I read somewhere they may have been painted red, so gave em a lick and then the transfer pipe on the side that passes the air between chambers looked like it needed brightening up, so that got the same treatment. The lever is original ash, just BLO and it looks fine. At some stage I’ll need to flip the frame so it blows the same side as the lever - a more awkward task then I expected. I spent an hour or two on the assumption I could just unbolt the frame , rotate the bellows 180 and bolt it back together, but over the decades of use in the past the cross rods have slightly deformed and wouldn't quite fit, when I switched it, so I need to plan ahead and get a couple of sons with muscles to help. A lovely object, and great to use with my similarly aged anvil and vices. It clicks and heaves and whispers as I use it, in a very relaxing peaceful repetitive sound - harder work but quieter than the noisy electric fan

-

Henry Rogers and Sons were hardware suppliers in Wolverhampton between 1830 and 1900. They would have sold the anvil but it may have been made by another local company. They did make engine parts so it is possible they made the anvil. They also made/sold safes. Their headquarrters was in Union St, Wolverhampton but they had international sales offices, and made or sold all sorts of metal and china objects. The founder , William Henry Rogers was a well known successful businessman, involved in funding railways, and also made significant benevolent donations in the area.

-

571 pound new to me anvil

RogerrogerD replied to SilentForge's topic in Anvils, Swage Blocks, and Mandrels

Fantastic anvil, fantastic price. If you can move it easily - i got one a similar weight but had to rent a tripod and winch to help me move it from a ladies garden, where it was an ornament. -

Historical forge welding of sheet steel

RogerrogerD replied to RogerrogerD's topic in Welding/Fab General Discussion

Sorry all one file now. Ping me if you want me to email you a cooy. -

Historical forge welding of sheet steel

RogerrogerD replied to RogerrogerD's topic in Welding/Fab General Discussion

I now have two files from the Indian investigation into metal cased rockets, one the words and the other the pictures. I think they will overwhelm the attached file mechanism. I can however email them to anyone who would like to see it. Its pretty interesting. Email me at the follwoing email address, inserting an @ sign where you see a capital A. (Doing this to stop spam). rogercdaviesAme.com If there’s a better way of making files available, let me know. -

Historical forge welding of sheet steel

RogerrogerD replied to RogerrogerD's topic in Welding/Fab General Discussion

Ok, got permission to reproduce the Indian analysis paper. i guess I can just post it as an attachment here? Would that work? Advice appreciated on now to post if its best to do it some other way. Thanks for your comments, slag, got all that and Ive written elsewhere about most of that - see the link I posted earlier. -

Historical forge welding of sheet steel

RogerrogerD replied to RogerrogerD's topic in Welding/Fab General Discussion

TP - They have done some sectioning and analysis, details to follow as soon as I get permission to post. Interestingly, Ive just seen that carbon comes out at 0.25- 0.35 % in some rockets and less in others. Other trace elements negligible. The metal is 2- 4mm thick, with an apparent clay coating on the inside. The end caps are apparently hammered on both ends. I hope to meet Dr Williams ar a meeting of the Arms and Armour Society at the Tower of London next week. I’ll try and get permission to post the paper written by the Indian Team. -

Historical forge welding of sheet steel

RogerrogerD replied to RogerrogerD's topic in Welding/Fab General Discussion

Thanks Charles, I’ll make sure they keep an eye out for signs of rivetting