-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by RogerrogerD

-

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

Well the trunk is going just fine. Four right angle brackets, each with two big screws into the ash, and then a concrete bolt into the floor on each one, and it still solid. The ash trunk has developed a few cracks/creaks but if anything that has pulled it all even tighter. I’m not sure about burying it, you may have to if you haven't a floor to bolt it to. It certainly doesn’t shift when I’m working stuff in either vice. Bark has come away in one or two spots, which is fine. If it starts to loosen up, I’ll try “frankensteining” some screw-in staples. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

Thanks Will! -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

I didn’t know that TP. Good advice. Strangely the stone is somewhat “eccentric”, (by about an inch). I can’t work out how it got that way, unless someone in the past kept it soaked… -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

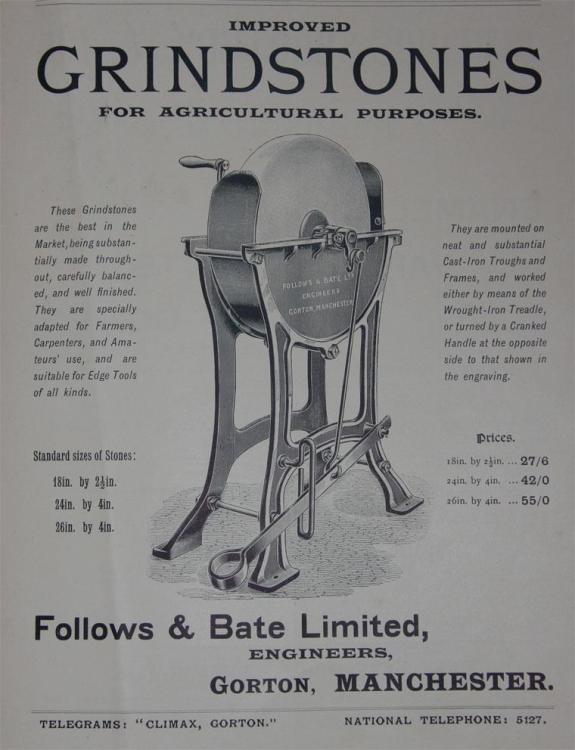

just restored this c1890s Farrow and Bate blacksmith’s grindstone to sit at the entrance to the forge. Before and after pics. Works with crank handle or foot pedal. iI intend to adapt it to run from a 1914 Amanco stationary engine I have up my sleeve. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

The grinder has a crank handle on one side, and a treadle on the the other, so both options are possible. I have an old “hit and miss” stationary engine from 1914, an Amanco, which I hope to be able to hook up at some point in the future - my wife refuses to do the duty of turning the crank… -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

Had to replace the central channel which was rusted through. Once I’ve finished the restoration, I’ll post a pic. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

thanks TW. I haven’t finished restoring it yet. It’s about 120 years old and was made by “Follows and Bate” in Manchester, England. Here’s a contemporary ad, and how I bought it. over the last couple of days I’ve been restoring these old 1930’s rusty pigeon hole storage racks. Getting my nuts and bolts, rivets, organised. I think they fit in with the “feel” of the place. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

yes, a nice trunk of sold ash. Previously it was a slightly dodgy alder trunk. That was a bit light and rotten in the centre. this will last a few years. It’ll form some cracks but should hold together well. Were it cracks I’ll add some odd bits of steel screwed in to form staples so it’ll evolve and it looks good too. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

-

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

-

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

I am inordinately proud of it. Another couple of weeks and it will be done, and then I can focus on using it not making it. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

And now the evenings are dark, electricity at last gives me the opportunity to spend more time here. Why would I not? -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

-

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

I won’t be heating the place TP. My old forge based out of an attached garage was never heated and it was never a problem. I wear shorts 11 months of the year, which my missus thinks is weird in the damp, but I like being “outside”. Our weather is mild compared to yours I’m sure. In winter its rarely below freezing during the day and snow never lasts more than a day or two. I’m fortunate that I’m doing my blacksmithing for fun in retirement. If it’s cold I can either: a. Wear more clothing. or b. Work harder and swing the hammer harder Or c. Stay in the house and shrug. also I don't want to cover up all that beautiful oak with insulation etc. I do have a problem with condensation in the shop on some days when there’s a lot of moisture in the air. Things will go rusty quickly but wiping things down with an oily rag is a constant activity. Not a big deal in the forge, but my lathe is suffering a bit and that worries me a bit. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

I usually run out of personal steam by mid afternoon, which usually means that I don’t forge in the evenings so its not an issue for me -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

i’ll be using largely LED lighting on the enclosed machine shop/ “clean” side. On the forge/“dirty” side, it’s open on the front and I’m trying to make it look “authentic” and I’ll normally work with no electric light, but I’ll hang a few edison bulbs from the roof for when I do need some lighting. I’ve only forged 2 or 3 times in the new place but I’m already finding the benefit of seeing the colour of the steel much better in a relatively dark environment. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

Yes, thats a good idea TP. A little roof that I can lift off, perhaps. I hope that we’ll get power plumbed in in the next couple of weeks. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

Vices. Two regular blacksmith post vices set up sunken into a slot and bolted down this morning on the old tree stump I have been using for a few years. The stump is slightly rotten and is not as rigid as I’d like, so in the medium term I’ll need a replacement stump. The other vice, set up outside the smithy (I know, I know but its most useful there is a circa 1895 Peter Wright parallel vice, that I restored a few months back. I’m a little unhappy with it as the jaws aren’t closing straight, so it’ll need some attention. Its the Uk so they’ll all be damp, I’ll keep oiling them up. The latter is on a chunk of “knotty ash” which although it has some creaks in it seems fine for now. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

-

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

Walls continue to go in, and this week got the chimney in, a bench for grinders, and my small anvil. Next few days we’ll get my big anvil in and a couple of vices on a tree trunk. also got some pigeon hole storage up at the back. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

I don’t suppose they are the cheapest, but I had some spare copper pipe and need some practice soldering as I’ll be using the same to install a compressed air system. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

i’m gonna hammer in the morning…. etc… copper pipe hammer racks now installed on one of the main oak posts, next to the forge. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

-

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

Rabbit. Steak and kidney. In this case though, fish pie. -

Building a new smithy and workshop in Uk

RogerrogerD replied to RogerrogerD's topic in Building, Designing a Shop

No walls yet but had a pal come round and make a plinth for my swage block with the offcuts of the building oak. Payment was a beer and a pie at the pub. ;- ) I’ll forge some right angles to hold the corners presently. It has a slot in it so I can stand the block on its side.