VainEnd84

Members-

Posts

155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by VainEnd84

-

Cheers for the replies, 22" is indeed short, outside of special ice carving saws I haven't found any that were less than about 38" many now being 42-48" My customer wants one for early ice, (5"-10") hence the shorter blade. I'll know one out of mild and one out of 4140 and see how they perform. Thanks again folks I'm curious, does your company/team cut ice blocks for ice sculpting or is it for something else?

-

It has been quite a long time since I have been on the forum and my search-fu skills are a bit rusty, so if this has been asked before I apologize in advance. I have been asked to make a "prototype" ice saw for fishing. Having never made something like this I have a question about what type of steel to use. I have mild steel, 1045, and 4140 readily available. I also have access to smaller sizes of 1084, 1095, 15n20. While stainless steel is generally preferable it os currently not an option. The design is based on an old Scandinavian ice and snow saw. The blade will be 22" long with half inch teeth that have a half inch space between them. My initial thought is either wholly 4140 or 4140 with forge welded 1084 or 15n20 tips on the teeth but I don't really know much about how steel works on ice. So to the actual question, of the steels mentions above what would anyone recommend? Any help is much appreciated.

-

Most of those steels are special order through Metals super markets and the prices are way above market value. I'm in central Alberta and I've been trying to track down h13 for about a year, I've called/visited 30 different steel suppliers who have it listed and so far it's cheaper to drive into the states and buy it there.

-

What did you do in the shop today?

VainEnd84 replied to Mark Ling's topic in Blacksmithing, General Discussion

Didn't have a whole lot of time in the shop today but I had a lot of fun forging my first spoon as part of the pub spoon challenge. I also forged my first flint striker from an old broken file, now all I need is to find some flint and try it out. -

Can you post some pictures of the hammer, that will give a better idea as to how to go about putting a leather grip onto it. Some steels rust more than others depending on the composition, even stainless steels can rust, it just depends on the conditions they are subjected to.

-

A quick Google search yielded this http://www.feblacksmith.com/org.htm if you scroll down a bit you'll get to France, I didnt check if any of the links were still active but it might get you going in the right direction

-

Ni! <In a night pitched squeaky voice> You must bring us a shrubbery!!!

-

I've heard some fairly offensive variations frosty, but that is the general idea yeah

-

On top of this standards from one city/state/province/region/country differ greatly

-

But a brain is roughly spherical so the volume calculation is V=(4/3)πr^3

-

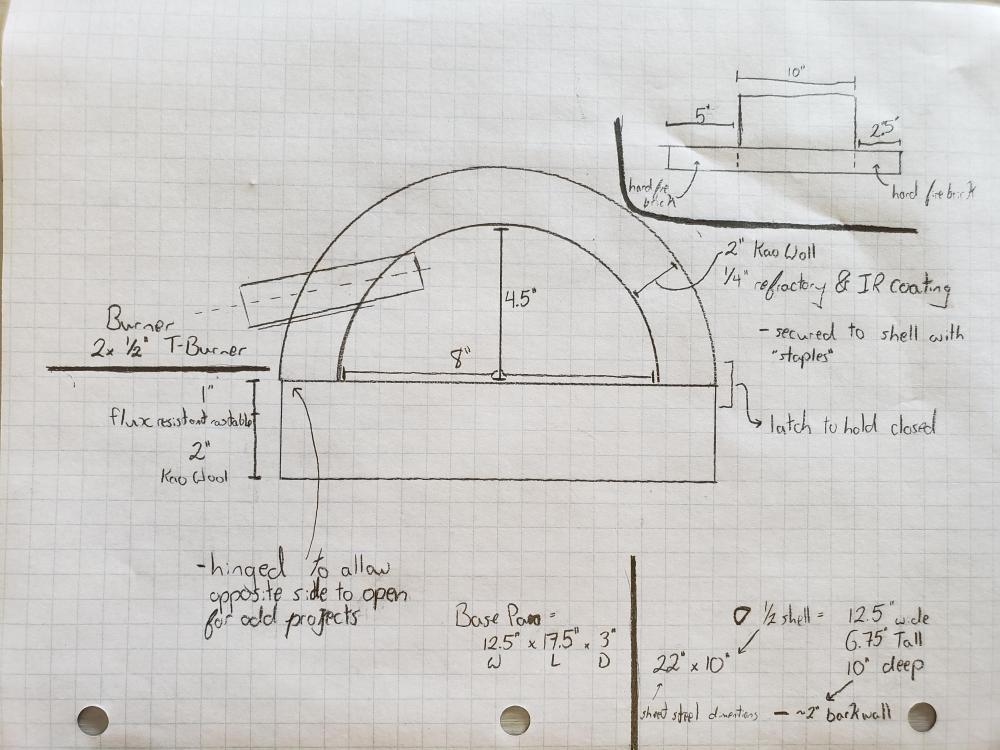

That's still enormous, at 16" long with an internal diameter of 11" you will have a volume of about 1520cubic inches, a well built 3/4" burner heats 350cubic inches to welding temps which means you will need 4 3/4 inch burners. That will be a gas hog. Now if you are set on a forge this size you can build an internal baffle wall to reduce the internal volume when you only need half of the forge, but even then it's still quite large.

-

Lou, that is looking really good, I love the idea of using the ducting, it's simple and looks to be very effective!

-

3D printed plastic burner experiments (photo heavy)

VainEnd84 replied to Another FrankenBurner's topic in Gas Forges

That's a thing of beauty- 863 replies

-

Blacksmithing gems and pearls

VainEnd84 replied to Glenn's topic in Blacksmithing, General Discussion

Many get confused and think we are making an object or item.. ( making a bolt, or tongs, or a handle).. Truth is we are making a skill set applicable every where.. jlpservices -

Lou I just dont think your trying hard enough Someone needs to forge a set of armour that looks like a baggy tshirt and khakis lol

-

Check out the following pinned threads: burners 101, forges 101, and the frosty T burner thread. They have all of that info and so much more.

-

Anvil trademark or logo

VainEnd84 replied to ImaRiverRat's topic in Anvils, Swage Blocks, and Mandrels

I believe it is an Eagle anvil, and I seem to remember them having some connection with the US navy -

The only issue is I have yet to find a supplier in canada that has their bricks, and shipping plus duties for international shipping is prohibitively expensive, plus I already have more ceramic blanket than I know what to do with. I have been looking into their products but haven't had success here.

-

I did not know the name though I have seen it in other application thanks! And I was thinking that over the width of the insulation 2 1/4" about 3/8"-1/2" height/deep for the peak and valley should be adequately strong.

-

I wonder if welding angle iron to the edges as a stiffener and continuing the kaowool/flame face to the edge of that would work? Another question, I've never welded stainless and only have a small mig welder which only runs fluxcore wire, would a heavier gauge mild steel angle iron work?

-

@Another FrankenBurner I like the idea of two hinges and just knowing out the pin, I've looked at Wayne's plans a long time ago and dont know if I even noticed that. @Frosty By not to scale I mean the measurements haven't been scaled back equally in the scale of the drawing. As for a heat shield I'm having a hard time picturing how to make one. On a related note I was thinking of having a bead of refractory at the junctions, similar to a horizontal S shape to help prevent heat loss. As for stiffening the long edges I was thinking of using my friends bead roller to add a ridge or two to stiffen that edge.

-

I'm working on a design for the new forge I'm going to build in the spring, my current forge works and works well but its dimentions are somewhat limiting for what I need/want to work on. I have several questions, since I want to hinge the burner side to allow me to open the opposite side for odd shapes, I'm looking for recommendations on how to stop the upper shell from flexing, I was thinking of welding a flange on the edges, thoughts? I'm also wondering how best to hold the forge closed. Just a note, the dimentions of the attached plan aren't to scale and the angle of the burner will be adjusted once the shell is built and lined.

-

I see a heart pendant in potentia, and valentines day is close at hand.

- 32 replies

-

I run 2 20lb tanks that are connected via a manifold, the same way two tanks in an RV are connected, my land lord won't allow any tanks larger than 20lbs so I had to improvise. Just another option.

-

If you are looking for info specific to casting I would suggest one of the casting forums as it is very different from blacksmithing. I think one of the bigger ones is alloy alley or something like that.