Bustapepper

Members-

Posts

32 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Alberta canada

-

Interests

All things metal working. Motorcycles.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

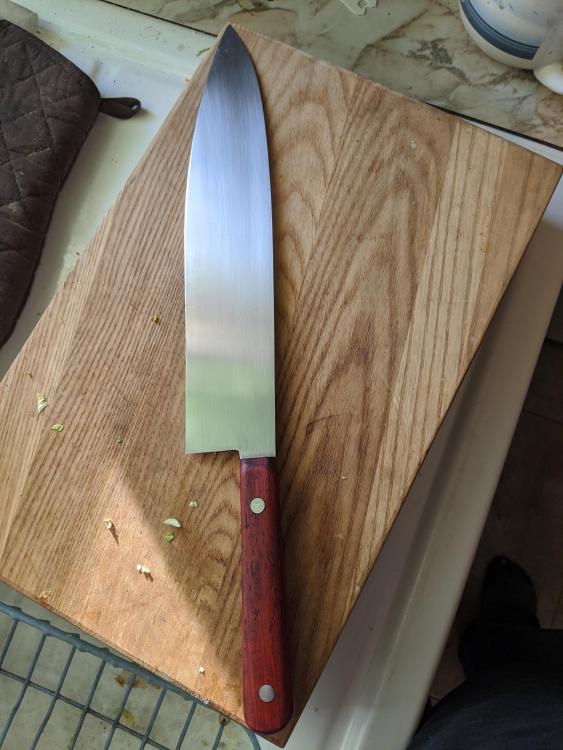

This is made out of the inner race of an skf bearing. On their website the metallurgy of this steel is 100cr6. Very similar to 52100. Just made the shape up to my liking, I forged the Fuller in and finished the profile up with my 2" wheel on the 2x72 grinder I built myself. Sanded down to 220grit. I cheated, this is my profile grind and I messed it up, so I used nail polish to cover the edge going up roughly an inch and dunked in some homemade ferric chloride I made from muriatic acid, nails, and 3% hydrogen peroxide. I don't have proper heat treating things yet so I just put the knife into my forged running very fuel heavy and slowly heated till the magnet didn't stick, then put back in for a minute or so to increase the temp slightly above that. Then quenched in preheated canola oil at a temperature hot enough where it was uncomfortable to have my finger in it for more than 3 seconds. I then tempered at 400f for 2x 1.5hour cycles, followed by a torch temper on the tang and spine to a blue color, and the very tip of the blade to a purple brown color. Handle is padauk with the pins being 3/8 stainless tubing. I even managed to forge in the distil taper I used West coast systems slow cure epoxy. I like how this one turned out. The knife is going to be living inside a camping trailer so I left it a bit thick on the edge in case it sees alot of hard use.

-

Just Getting The Ball Rolling

Bustapepper replied to Mulebrain's topic in Blacksmithing, General Discussion

My first project was a set of flatbit tongs. I used an old hexagonal shaft and pounded it into shape getting instructions off of YouTube mainly Blackbear forge. I'm a lefty so his description of how to build tongs was good for me. I built one half and the jaw broke off giving me rage and I wanted to just quit because it was hard work. I pursued on and finished the tongs. They are ugly but work ok still. It is alot of hard work. And you will suck. But time and patience will make it better. I'm still a beginner and am still learning but I think I'm past the hump of wanting to just give up because it's hard work. Go slow, and focus on proper hammer technique. Also slowly shape your hammer handles to suit your hand properly. I'm still refining my handle shape. Like I said it's hard work and you will feel like you are getting nowhere, then you will get frustrated, and just want to give up. But it's hard to explain. But it will just click and it will get easier and more fun as time goes on. Don't forge a sword as your first project. Don't give up. -

2nd forged knife after long break from the anvil

Bustapepper replied to Bustapepper's topic in Knife Making

I was thinking the same. I didn't like the way it has a sharp corner on the choil. I'm going to leave this alone and use it as reference for my next blade and kind of have an idea what to improve on. -

some Work in progress but I made this out of an old coil spring. Just a practice knife to learn. I had alot of fun. The pins in the handle are actually just a couple old bolts I cut down to size. Wood is padauk with a light coating of linseed oil. Sanded down to 320 grit on the blade. I originally was going to build it out of an old skf bearing race but when I quenched it, the blade got a warp I wasn't happy about so I quenched a 2nd time and got micro cracks along the spine of the knife going down about an inch. So I just started over and this is my result.

-

I got the motor for really cheap. The motor or a 5 inch pulley down to a 2.5 with the drive wheel attached to the driven shaft. I will have a vfd powering it. The power supply is limited in the garage at 20 amps so unless I upgrade my electrial panel and run 220v out there I am limited. I can't afford to do that at this time. I currently use a 5 inch angle grinder. So even if the motor bogs I think I'm a little better off than nothing.

-

I am wondering if the 1hp motor is going to be ok? If anyone has done this? I just want a motor to run off my 110v power. with a vfd Setup is going to be a 2:1 speed increase, motor is 5inch pulley, driven shaft is a 2.5 inch pulley and attached is a 7inch drive wheel to drive the belt. I know in an ideal world a 2hp would be the way to go, I just got this motor for really cheap. Using the formula 1760rpm2 x0.264x 7 = 6523 surface feet per minute. Just curious is all. Thanks for the input Edit: motor is 1760rpm

-

I'm really new to all of this and appreciate all the input. I value all of it. In reality I do not know much. I am learning as I go. I'd rather find out I'm making mistakes now and correct as I go rather than just learn the wrong way and then have an unstable footing too build off of. You guys are right. I don't really know the junkyard rules like I should, and I'm just going off of the steel has to be 5160 because that's spring steel. I did do the tests, but I don't have a known source to base my tests off of, my spark test cant be valued because I don't have a known source, I have read and have discovered that there are too many factors on used springs due to micro fractures and stress that will show up especially on a strucken tools at a later date and possibly be a hazard. I will keep educating practicing and asking lots of questions when the time comes. Like I said I won't take it wrong. I know it's all in good spirits to pass on knowledge to us rookies to have a good roots to build from. Thanks for that and always will appreciate the input

-

I'm a self learner. Self taught. Not the most proficient way to go about it. I know I will gain a ton of knowledge of just getting hands on experience with a more skilled person. Which I will do in due time. I didn't get out to CanIron. Would be nice. But work schedule conflicts. I will always take the criticism, I will thicken the boss area, and keep the stress points thicker. Well I'll try my best anyway. I think I'll make another set of tongs in the near future try to get better, I kinda like the challenges.

-

This is very useful information. I can't for sure say if the spring is 5160. But it is very good steel that slightly air hardens, I determined this with a triangular file, I heard these are the hardest files. and I tested a quench in water and it didn't like it at all, micro cracks so I determined it is oil hardening. I was wearing my safety glasses too. I only got two eyes. Also the Sparks are very explosive like little sparklers going off, Also when planishing the hammer dents out is it ok to lightly tap minor defects out at a dull red to black heat? And since I'm not doing heavy hitting and forging can I consider this normalizing? Or is normalizing cycling from critical temp, or slightly past magnetic down to room temperature? Like I said. I will follow the junkyard rules of mystery steel. It is very high grade, new these babies cost $1600 Canadian so they are pretty high grade I'm guessing.

-

I like them. I used them now to build two tools from a spring I salvaged from the scrap bin. They aren't totally secure, but they work. Thanks for the encouragement. Makes me want to keep doing what I'm doing and slowly refine the skills. Cheers

-

This 2nd tool I have made in my new hobby and was wondering about the temper after the heat treat? I heated to a dull orange and quenched in preheated used motor but only up to the start of the taper. I heated the whole tool up and then let the radiant heat soak it's way up to the top.leaving the octagon section to just air cool to stay soft for the hammer blows Probably a 5 minute process to let the tip turn to an almost dark brown/ purple color. My theory is it's going to be abused shockooaded/side loaded and would rather a softer rather than hard and have the chance of shearing. The parent spring is a 7/8 thick coil spring off an industrial vibratory shaker. Before I worked it. I heated it to an orange just past bright red color,, straightened it and put it in my forge with the openings closed off to cool down slowly overnight. I don't know why but it seemed like a good idea at the time. Like I said, I was wondering about the temper to bring it too being a cold working tool that will be hammered, beat up and put away dirty. Thanks for the input. Here's a couple pics if your curious.

-

Built my 2nd set of tongs today. Sized them for 7/8 round bar. Fits 1 inch as well. Not the perfect grip into the bar I wanted. But they will do I think. Lots of practicing and lots of skills to be learned by building tongs I am finding. It is a pain to draw out the reins by hand but as I do it I am learning new technique, and proper hammer control. I went with the more extreme curvature because I think it looks kinda cool. Anyway from what I see out there they are far from perfect, but like I say, I had fun building them. Material I used is an old hex shaft that was in the scrap bin at work. Figured I'd use it. Cheers!!

-

To drill stainless in my opinion use cutting fluid for drilling. And go half the speed you normally would with a little extra pressure. Slow and steady is the way to go. Stainless is very gummy material. Very tough.