-

Posts

1,746 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Anachronist58

-

Yes it is possible to change out the jaws on some on some pipe vises, not possible (unless one can make the jaw(s) one's self) on others. I had to make my own top jaw for my big pipie vise - not a job for those with limited "resources". Robert Taylor

-

Qb, that is an odd thing to say, as we cannot answer a question that you have not asked. Please correct me if I am mistaken... To answer your new question, can you imagine a use for it? I have one mounted adjacent to my post vise, and find it to be quite handy. Be sure it has a complete set of jaws - top and bottom. That is what makes it valuable, or not... We can not tell much about its value from the grainy image prvided.... Robert Taylor

-

Once again, going off the rails on a crazy train, but I must say, I will restrike the OP gong and say: A venerable member of this body has published his moniker, 'bei hammer and hand, all arts do stand'. I take this to heart, as iron, ()oxides, and on and on, of alumnina, et al., all rise, often closely bonded [...]. That being said, the first thing I tend to ask a thing is, 'Are you a bell? Do you rIng?' Robert Taylor

-

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

Glenn, Depends on how fast I get. Were it profitable, I would make hundreds... The current tooling is adequate for giving them away as gifts, but not for sales... the drawing and blanking can be sped up substantially, but I am enjoying the texturing a bit to much to mechanize at present. I am just grateful right now to be able to walk and breathe :+D... Robert Taylor -

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

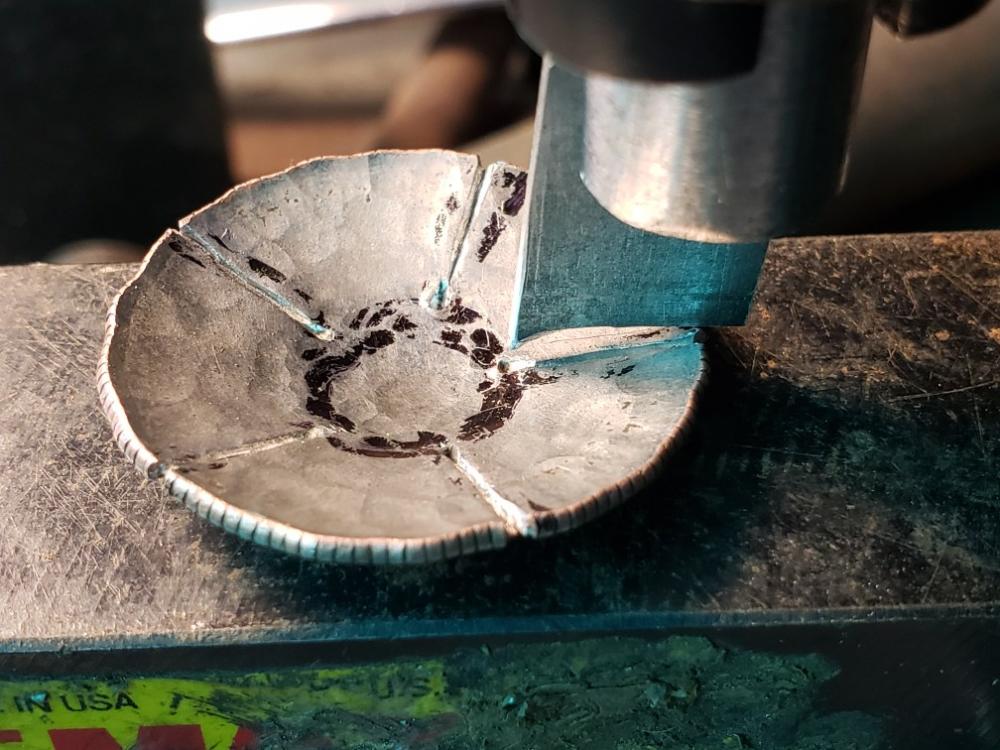

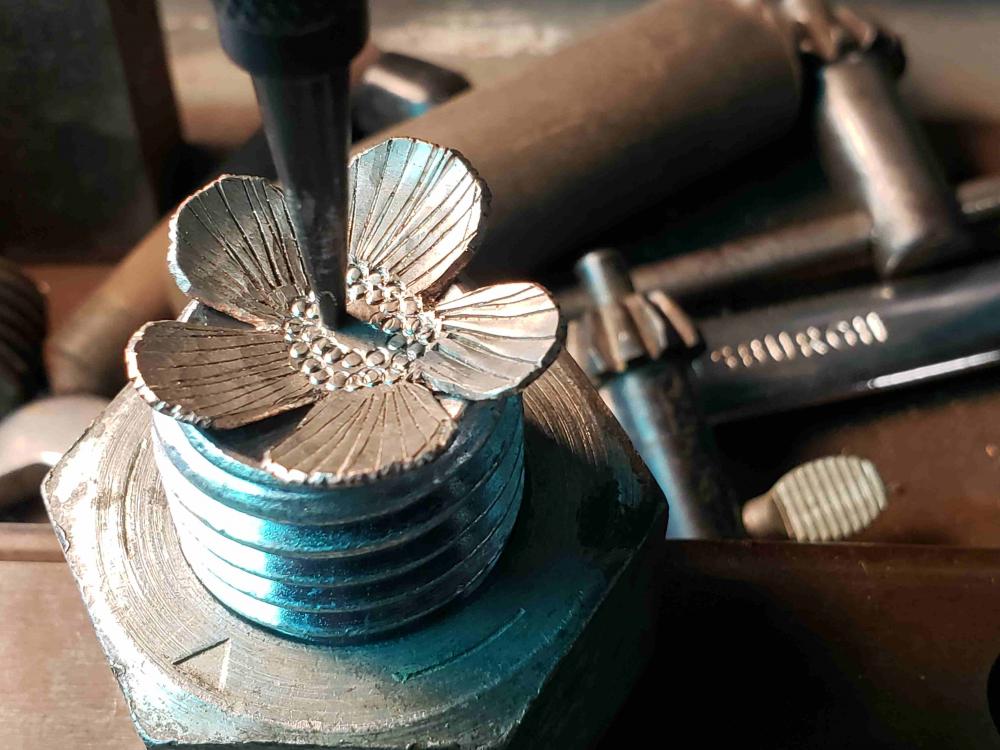

Second iteration of two bit flower. Now I develop a set of feature-driven dies: Knife blanks from bimetal commercial bandsaw blade: Had to thin this file to .041" thick to finish the blade holder: Time to slice and dice: And here is the kaboodle: Note to self - do not vein the petals when fatigued and up against a deadline... these are a good bit more inconsistent than what I was going for: Driving up to Ventura, California, today to deliver the goods. Thanks for looking, Robert Taylor -

Frazer's Corner of the Internet [photo heavy]

Anachronist58 replied to Frazer's topic in Member Projects

Well done, and all of the praise thus far is rightfully earned. Having read all of page seven of this thread, I must now start on page six! Robert Taylor -

Little nickel cokes in a stand up machine at the gas station on Telegraph Canyon Road! Robert Taylor

-

What did you do in the shop today?

Anachronist58 replied to Mark Ling's topic in Blacksmithing, General Discussion

Stove elbow endured fifteen years of heat and weather cycling - no complaints. This week when I slammed the front door on the furnace, it just went blehhhh... all better now! -

Welcome from San Diego to Santa Barbara! Robert Taylor

-

JLP Blacksmith Teaching Center.

Anachronist58 replied to jlpservicesinc's topic in Building, Designing a Shop

Congratulations on a successful tear down, Jennifer. And thanks for the comprehensive narrative... When the machine guard craze ran through my last Aerospace plant, it was very disruptive. Fortunately, we were able to keep the "fixers" out of the Tool & Cutter dept., as many operations have to be open gear, period. ('nose to the grind stone' is not 'just' a saying). Guards where they are sensible, but we do love to to see fine machines doing their stuff... Robert Taylor -

What did you do in the shop today?

Anachronist58 replied to Mark Ling's topic in Blacksmithing, General Discussion

Having abrasive cut a lot of tool/high speed steels, I would say that you are on to something. I have found that in the perfect storm, (four?) factors can bring trouble: The abrasive cutoff process is, in part, incendiary in nature. The sharp grits of the wheel cut chips nearly identical to short mill cuttings, and these chips, as they ignite, efficiently carry nearly all of the heat out of the cut zone. If the wheel's surface speed falls below the necessary minimum, that process ceases. This causes the the wheel and/or the work to overheat: the wheel grit can melt (glaze), and the cut zone can work harden and/or oxidize. Efficient cutoff is sustained by cutting, not rubbing. What to do? Obtain an inexpensive single point diamond to remove wheel glaze. Do not allow heat to build up in the wheel and work - allow the wheel to run and cool the work. If the work needs more time to cool, shut off and come back (I would have to employ more aggressive cooling due to production demands). Feel, speed, and spark are very important feedback... If you feel your wheel speed dropping, get out and peck. Worse case (if possible) - rotate you work to expose fresh meat... One should find that most cutoffs in a well tuned process are like hot butter... constructive criticism always welcome... Robert Taylor -

What did you do in the shop today?

Anachronist58 replied to Mark Ling's topic in Blacksmithing, General Discussion

That puts it completely into context! Thank you. -

What did you do in the shop today?

Anachronist58 replied to Mark Ling's topic in Blacksmithing, General Discussion

"dovesti do uma" Alexadr, Google translate: "bring to mind", which could be said as: "remind me of"; "make me think of"; "look(s) like beautiful, perfect, roses"... Better translators than I, on this thread... Robert Taylor -

Are they worth getting?

Anachronist58 replied to Dillion Brian Grant's topic in Blacksmithing, General Discussion

As stated, what is the asking price? I would certainly like to get ahold of a couple of those spike heads if you wished to have part of the purchase subsidized... Just saw your latest post pop in. Where is that decimal point? Robert Taylor -

Bantou, I would say that would be pretty snazzy from where I sit... I am compelled at present to chain my anvil down, but it employs a semi-quick release. Thinking I might try that myself. I use chain binders around the property, love em... Robert Taylor

-

Looks like the "standard" flat spring has been replaced by a coil spring... Robert Taylor

-

Wow! That is some spread! Inspiration, Indeed! Robert Taylor

-

Maybe that co-worker isn't incompetent...

Anachronist58 replied to rockstar.esq's topic in Everything Else

The business world will always appear operate along a baseline of inexplicable madness, as viewed by a select group of observers. Perhaps a mixture of charity and utility drives the retention of such individuals. Sometimes a rickety framework is superstitiously protected, because it "works", much to the frustration of more perceptive outsiders... Robert Taylor -

Prayers for my wife and her mother Sara...

Anachronist58 replied to Irondragon Forge ClayWorks's topic in Prayer List

That was close! Thankful that things are on the upswing... Robert and Sheila Taylor -

Very sorry, Steve, please live through this. The loss of my Brother last year was a similar type of very rough ride.

-

Lary, you just zapped me with a vision of a three layer welded spike knife. Thank you. Robert Taylor

-

Very nice, lary... Robert Taylor

-

Never say never. But of course, I see his intent, and it is fun imagery... Robert Taylor

-

I can not help with the Identification, but from over here, that looks like a nice, crisp screw! Robert Taylor

-

Very sorry that this has happened, and is happening. Our prayers go out for Tammy and her loved ones. Robert and Sheila Taylor