Ted Ewert

Members-

Posts

557 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Mill Valley, CA

-

Interests

Building stuff

Recent Profile Visitors

1,709 profile views

-

Like I said, there have been hair samples, scat samples, videos, photos, and even dead bodies. There is no lack of evidence. You just haven't heard about it. But why then hasn't the government and the scientific community come out to verify these numerous findings? Well, they have. The government knows all about Bigfoot. So does the park service. Yet, they all remain silent and will deny any knowledge of these creatures. Anyone who hasn't done their own research will roll their eyes at that last statement. People who have done research will verify it.

-

George, if you do some independent research you'll find that there's plenty of evidence supporting the existence of Bigfoot. Start with the Patterson / Gimlin film and go from there. There are photos, videos, tons of footprint casts, hair samples, recordings of vocalizations, etc. The thing to keep in mind is that these creatures are, for the most part, nocturnal, shy, elusive, and try their best to stay away from people. Nevertheless, there have still been thousands of sightings and interactions with these things. Farmers, ranchers and rural property owners tell of living with families of Bigfoot for generations. There's a huge body of information on these beings if you're curious enough to look. Listen to a few accounts on The Bigfoot Project on YouTube if you're interested.

-

I'm a veteran rabbit hole adventurer. I've got a whole library on paranormal phenomena. If it's weird or unusual, I've researched it. It started back when I was a teenager and watched a UFO fly over a buddy and me one night. It was a classic disc-shaped craft that went from a light yellow on the top to a deep orange on the bottom. We watched it fly from north to south for about 5 seconds then disappear into a fogbank. The ridicule and disbelief from my family and friends taught me a few things. The main lesson being that most people refuse to think outside of societal norms. Anything that doesn't fit into their comfortable worldview becomes an "extraordinary claim" requiring "extraordinary proof." I don't think that way. I rate things on a scale of probability, not if it's true or untrue. Take Bigfoot for example. I've never seen one but I've read credible books and listened to hundreds of eyewitness accounts of these creatures. They all describe the same large, hairy, bipedal creature. Many have physical evidence to back up their claims. They all describe similar behavior and other traits associated with this creature. These testimonies come from a wide range of individuals including police officers, firefighters, judges, geologists, soldiers, and many other reliable sources. The evidence is overwhelming to anyone who doesn't dismiss the whole phenomenon out of hand as a crazy, tinfoil-hat "conspiracy theory." I would rate Bigfoot's existence as extremely probable. Having an open mind is not always synonymous with being a gullible idiot. If you wait for academia, the government, or the "experts" to tell you what to believe, your knowledge of the world will be extremely limited. Using your own intelligence, logic, and common sense to explore the fringes of our knowledge is far more fun and rewarding.

-

I recently acquired this vise from a friend who had it for many years. He said he bought it for scrap price when the company he was working for went out of business. It's a machinist vise with 4-1/2" jaws and weighs in at just over 100lbs. This particular vise was built sometime before 1957. It's in very good condition considering its age. I regreased it and cleaned it up a bit, but it didn't need much. I really like the swivel lock on this vise. This vise replaced a Wilton I've had for 30 years. The Wilton never locked down well and would break loose and swivel under load. I don't feel at all shy about beating hot metal on it either.

-

What did you do in the shop today?

Ted Ewert replied to Mark Ling's topic in Blacksmithing, General Discussion

I haven't checked in lately but I'm still making stuff. Here's a few things that have come out of the shop lately. -

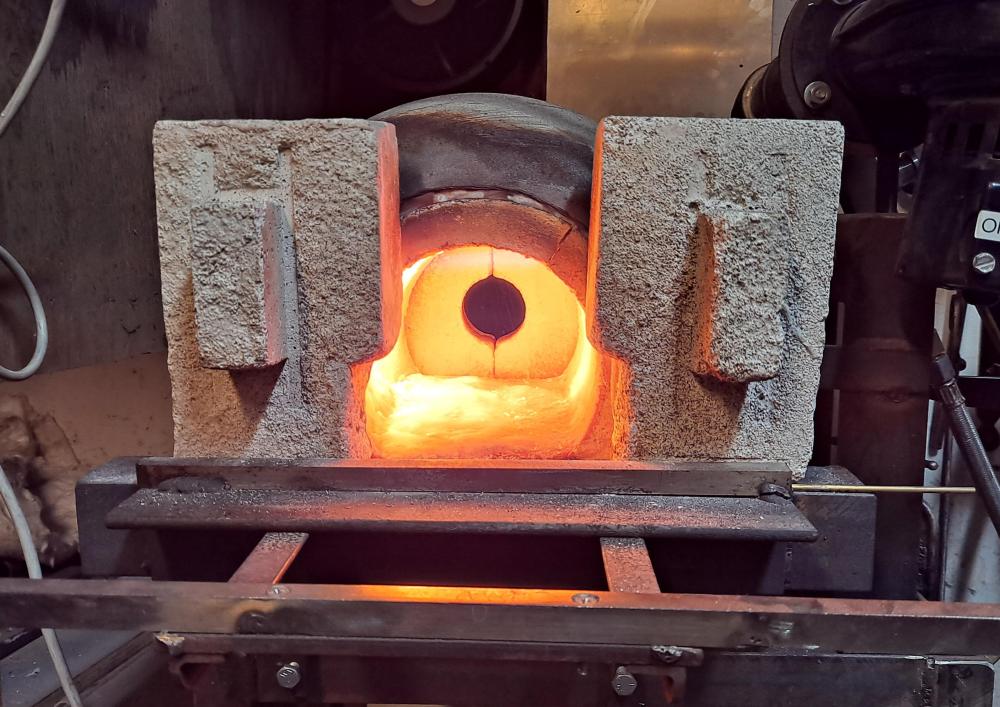

I took a couple of pics to show the flame path. The first one is on start up. The input ports are about in line with the crack in the shell. The blue is where the flame is igniting. The second is the forge after its warmed up a bit. At that point you can't see the flame anymore. One note, I removed the rear tube so there are now 4 tubes feeding the chamber. That's plenty for me. The rear of the chamber stays a little cooler which I prefer. I've had to recast the chamber once since I first built it. Otherwise it's been a great forge.

-

What did you do in the shop today?

Ted Ewert replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Ted Ewert replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Frosty. A couple of those will go to the grandkids, the others I'll sprinkle around the house. I've only sold one thing I made because it was a request from my boss. Even then, I only charged him because I didn't like his attitude. Otherwise. I much prefer giving stuff away. -

What did you do in the shop today?

Ted Ewert replied to Mark Ling's topic in Blacksmithing, General Discussion

-

This is a medium / light duty swage block which is anchored in the hardie hole so it doesn't dance around much. The concrete is merely a filler and stiffener and bears no real shock loading. I welded in some rebar internally to provide support for each swage. I've used this block quite a bit and it accomplishes what it was meant to do. I've been keeping my eye out for some material to make a dish swage.

-

What did you do in the shop today?

Ted Ewert replied to Mark Ling's topic in Blacksmithing, General Discussion

I saw this in an old video about Welsh clogging (dancing). It was being used by the clog maker to carve the wooden shoes. New to me anyway, so I thought I'd build one. I designed my own pivot stand which allows the blade to swing and tilt. It's made from an old leaf spring. I tried a standard edge grind but found a chisel grind works much better. It carves wood quite well, from big chunks to small cuts. I've got no real use for it but it's fun to play with. -

Neil has a point. Smaller stock will work for tongs. The problem comes with over forging the different elements, which is common when you first start making tongs. I have a number of sets which fall into this category. They're perfectly usable, but only for light work on the anvil. If you plan on getting a power hammer down the road, you'll be glad for some sturdier tongs. I have a couple of Ken's box jaw tongs. They're very sturdy and easy to make. A good choice if you're getting started or plain don't want to make some from scratch. They also make a good reference for building your own.

-

What did you do in the shop today?

Ted Ewert replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Dax. JHCC, what's the jig for? -

What did you do in the shop today?

Ted Ewert replied to Mark Ling's topic in Blacksmithing, General Discussion

Made a towel rack today. Used 3/8" rod for the twisted part and found it's not easy to get an even twist over that length (16"). -

3/4" square stock is perfect for tongs, especially starting out making them. It provides that extra material to correct minor mistakes and still have enough left. I rarely forge material bigger than 3/4" anyway, so most of my tongs are on the smaller side. Never tried vice grips.