-

Posts

3,598 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by John B

-

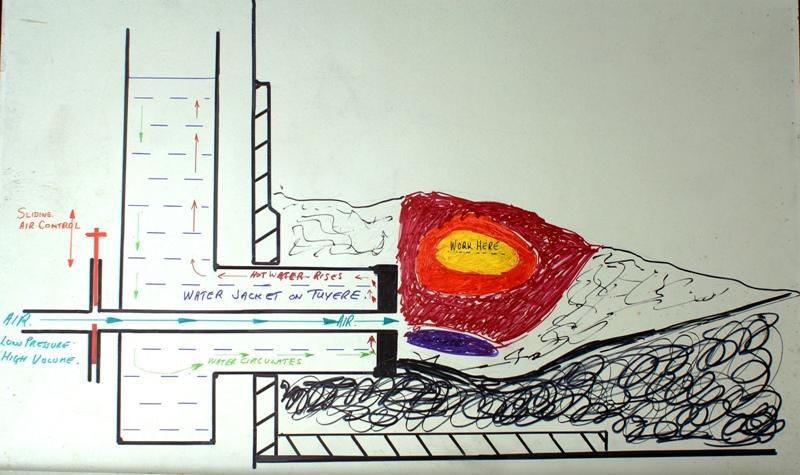

Hi Tom, whereabouts in the UK are you? This is a sketch I made for students coming on the courses at Westpoint in Devon, to try to illustrate/explain the relevant theoretical workings of a side blast hearth, the proportions of the nest in front of the tuyere will depend on the size of the work being done in the fire. In practice the sand/ash tends to level out with the top of the tue, and new fuel is added from the rear to maintain the overall height of the fire, the hot spot/working area is above the air hole in the tue, you need space between the sand /ash under the front of the tue to allow for the clinker to settle and collect, but if you pack it as illustrated, the clinker should not form under the tue making it difficult to remove. Key in using these hearths is fire management, and positioning of the workpiece, far too often I see fires far in excess of what is necessary, due to too much air being used, this just wastes fuel, creates clinker, burns the outside of large section metal before it is thoroughly soaked through for forging. The other thing students tend to do is to poke the metal into the clinker area, rather than lay it at a shallow angle or horizontal into the hot spot area. When clinker becomes a problem, you can tell by the heat spread on your workpiece. This is usually identified by different heat colour bands on your workpiece IE where clinker is, the air gets deflected /dispersed and gives a fiercer fire around its periphery, so what happens is that where you are expecting to get your work hot in the what was the hot spot, but due to the air deflection the hot spot(s) have moved, and your workpiece gets hotter or burns where you don't expect it. Each hearth has its own idiosyncrasies, but the theory is the same. In the picture the tank/tuyere is tilted to allow air bubbles not to be trapped at the front of the tue . this was done because ordinary tube was used to con Have fun The tank/tuyere shown is tilted slightly so there will be no air trapped behind the front plate allowing the front to burn through. traditionally the tuyeres were conically shaped so this problem did not arise.

-

Hi Joe, Welcome, wood chisels can easily be made from old files, depends on what they are intended to do, and their profiles as to how you make them, for straight forward tanged style chisels, a heat source to anneal (soften the steel) and then you can use hand tools to shape and finish them, then back to the heat source to harden and temper them for their intended use. For socketed chisels, then you will need 'smithing type resources, there should be someone near you who may be able to assist with loan of facilities or even doing the basic work for you. You are in danger of getting into an addiction should you choose to start down the forging hot metal path. Enjoy and have fun

-

Does smokeless coal work?

John B replied to Rainbows's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Depends on the user and their opinion, check with other blacksmiths in your area what they use and where they get theirs from -

Does smokeless coal work?

John B replied to Rainbows's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Often smokeless coal is not smokeless, just a different colour smoke, There are many varieties of smokeless coal/fuels, what brand name is the stuff you are thinking of using sold under? The Monkton Forging coke is becoming no longer available relatively soon, and a lot of UK 'smiths are turning to a coal, semi smokeless (whatever that means) from an open cast pit in South Wales, Ffos-y-fran who supply a welsh dry steam coal, the large nut being most favoured. It is also cheaper than the Monkton forging coke http://www.coalmerchantsfederation.co.uk/products/welsh-dry-steam should give you a local supplier, or Darch Fuels (among others) will palletize and have delivered to you. If you don't want to upset the neighbours, use lumpwood charcoal. Have fun -

Try using typing correction fluid, if it's available where you are, a lot more visible than soapstone at a high heat

-

Filing is usuallya whitesmith/fitter/engineers operation rather than blacksmithing, the vise being suitable and positioned for the job being done, as a general rule fig 4 would be best practice for a 'smithing situation, also useful when using a hacksaw. Geometry of the body parts would dictate the best height, in this instance so you can achieve a flat face square to your stance. Similar rules apply to using a scythe or other hand powered tools in other industries/situations.

-

We have a number of blacksmiths in the area, Axminster is about 28 miles/45 km's from our training facility, you would have been most welcome to have a visit and a chat, maybe a play time too. Maybe next time?

-

It is always fascinating in historic places where visitors abound, playing guess what bit fits where, and what does it do and how do you use it. Some years ago I had a similar enquiry from someone in your part of the world NZ iirc who was in a group trying to bring an old industrial unit back to life and they too were trying to figure out what a similar item was, and how it was used. Sadly, i was not kept up to date with the progress, but these things are usually a very long in coming to fruition for various reasons, usually financial and red tape. Enjoy your curator's position for future generations to benefit from.

-

I'm pretty certain your informant was correct, they appear to be side blast water cooled tue irons/tuyeres, not particularly large, previous ones I have been involved with with inlet and outlet connection facilities were over three feet long, the size will depend on type of work being undertaken. These are industrial units, and were usually connected to a heat exchanger, commonly a coil within a large tank, the tank being fed through a ball valve arrangement, to maintain the water level, and the heated water could then be used for other purposes within the locality/facility. You mention 'your visitors' so are these part of the industrial debris around a local heritage/visitor attraction, (Which may give somewhat of a clue as to what the secondary use for the heated water may have been used) or just people visiting where you have them?

-

Hi Colleen, for levelling and assembling on uneven floors you can use hop ups/saw horse type supports, axle stands, wedges and spirit levels,

-

Do i have to be artistic to be a blacksmith?

John B replied to Seth O's topic in Blacksmithing, General Discussion

Become a blacksmith first, then you will develop into being artistic as you go. You can qualify blacksmithing, but art is a perception. -

I was running hearth, drill, lathe, Blacker powerhammer, all in use at same time, then angle grinder, hand drills, spot welder, welding plant, oxy burning equipment, all were found to be acceptable. Also don' forget to emphasise that forging hot metal is less noisy than just bouncing off cold metal or the anvil, so if possible take a hearth and heat up the metal, make something as a souvenir for the testers.

-

Hi Joel, Although I didn't "need" planning permission when I applied for it on a converted farm machinery storage shed, I nevertheless applied for it and it was granted with certain provisos, in my case, 8.00 am to 6.00pm no Sundays or Bank Holidays, There was a complaint after a couple of years from a neighbour and the Sound levels were tested, and they were found to be not excessive, I had checked it with a decibal counter and it was below 90dcb's, however the decibel measurement is not discussed, it hinged on "acceptable" levels,, and mine were thought to be well in limits. The interesting outcome was that although I had planning permission restrictions (as a business) I could forge outside those times as a hobby. Complaining neighbour later had a restraining order put on them for excessive noise from radios etc. Ironic or what. If the tenant is in a tied cottage, then that opens up other avenues. Good luck with the outcome.

-

Hi Stephen, Welcome to the site and enjoy your new hobby. Check out the Blacksmiths Guild UK in the Groups section, and also our website wwwblacksmithsguild.com to see what we have going on,. We are not far from Exeter airport or the ports of Plymouth and Weymouth, If you are venturing over here we would be glad to see if we can help you in any way. Have fun !

-

Tension VS Compression bracing

John B replied to Joel OF's topic in Blacksmithing, General Discussion

Function of the finished item is paramount. and the design of the component parts and their layout should reflect this To Quote HW An example might be an L-shaped sign bracket hung on a wall. A support bar that forms a closed triangle would therefore hold more load if the hypotenuse was on the upper side. However, in decorative blacksmithing, we should also consider the fasteners and other elements as potential failure points. A bracket like this may hold more load, however there would be more leverage on the upper mounting point which could prove a potential safety problem, -

Hi Matt, Welcome to the site, put in your location and there has to be someone who can help near you. Check out the Blacksmiths Guild UK in the groups section. We have numerous sledge hammer heads, forging stakes and other useful items that can be purchased by members, Plus other help we can give. Enjoy your new addiction.

-

We will be holding the Guilds AGM at Westpoint EX51DJ on Saturday March 28th at 11.00am there will be a buffet lunch available after, bring along any tools or other blacksmith related stuff to sell or trade, forging and demo's through the afternoon and an evening BBQ and hoolie with Merv and friends. Day will start at 09.00am for putting up marquee and setting out stuff, refreshments and bacon butties available. After the business part of the meeting Terry Clarke will be informing us about the 2016 Ypres Cenotaph of remembrance project, and Sally Clarke will be talking about the Worshipful Company's Tonypandy award. After the IBF, this is a crucial time in developing the future of the guild, so if you want to be part of that, come along and join us, Sunday will be a forge in day, I also have details of a load of surface rusted steel going begging, if anyone is interested pm me.

-

You can walk away if you choose to, but keep an ear out for when the blade jams and if you don't catch it in time the motor overheats and the thing catches fire, As for swivelling arms, it can take as long to set up as a swivelling vice, and the structure of the bandsaw is somewhat flimsy Have you considered using an chopsaw for mitres or even cut off, the local farriers use these and they are surprisingly good, more info here http://www.evolutionpowertools.com/uk/steel/evosaw180.php

-

Personally I would go for a good old fashioned power hacksaw aka Donkey saw, they will far outlast the majority of bandsaws on offer, Plus you can let them run on their own happily, whilst you get on with other things

-

Pillar drill buying advice

John B replied to Joel OF's topic in Drills, Post drills, Mag drills, etc

Hi Joel, Looks like a sound piece of useful drilling machinery, but how much of an update is it from your existing drill? And what differential value would you put on it, against the purchase of a new one with guarantee. Does it work? how accurate is it? what advantage does it have over the existing unit? Table swivel adjusts to incline? or fixed at 90 degrees to spindle If it does go wrong are you going to have hassle with its previous owner ? (not unknown for mice nests in motor etc) Or would you want to invest the money towards something which would be suitable for now and your future requirements, Your call at the end of the day. -

Pillar drill buying advice

John B replied to Joel OF's topic in Drills, Post drills, Mag drills, etc

Hi Joel, just to add to Alan's advice, 750watt single phase with industrial rating usage is advisable, also a rack and pinion table height adjuster is definately recommended From a practical point, you do not need the high speed rpm range, and with stepped shank drills you can drill up to 25mm + diameters relatively easily. -

Ay up Carl, welcome to the site, you need to do a bit of lakin abaht and then have a go. As mentioned previously you can find us in the groups section Blacksmiths Guild UK, If we can be of assistance either bring it up her or cantact me through the website link for courses. Good luck wi' t' new addiction, and have fun.

-

Another UK supplier is http://www.leggbrothers.co.uk/en/pure-iron/, they are part of a larger group who supply internationally http://www.allsteelstrading.co.uk/ and were looking to market and distribute in the US a couple of years ago, may be worth an email to see if they have outlets over there.

-

If the gate is tight, you could step it back and mount to the rear of the verticals.

-

Thank you for the comments, glad to be of some assistance. Regarding the eyes, funny old things eyes, they are recessed and yet pop out, With the owls, most have a seemingly flat side at each side of the beak/eye area, and by punching in at that area to create the flats on the round bar, it raises the centre to allow for the beak being created. (These could be flat punches with a recessed ball punched centre, much like a domed rivet head snap but with a larger outer area, that would then give bulging eyeballs.) As for the beak effect , it was done using a small curved chisel, you may be able to see more clearly on this enlarged/doctored pic The incisions also move a little more metal to give a slightly more raised area which fools the eye into thinking its a beak. Much of animal effects are judged by the eye, and the overall effect, and are not really what they are like, it looks like a beak, this method also does not leave a sharp pointed area to be a danger area as it would be if you went in with a chisel, an alternative method to raise the beak. Also makes it more tactile and usable if used on key rings, bottle openers etc.