-

Posts

665 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by M.J.Lampert

-

What did you do in the shop today?

M.J.Lampert replied to Mark Ling's topic in Blacksmithing, General Discussion

if we really want your thoughts we'll give ya a loonie, if we think your absurd we'll call you loonie -

What did you do in the shop today?

M.J.Lampert replied to Mark Ling's topic in Blacksmithing, General Discussion

i like the center finding tool idea will look into it dave I am using a hack saw so that adds half the time again luckily I'm not going for the profit right now just for fun(and maybe cost of materials) i tried a zip cut wheel but ended up damaging one of the arms so i finished it with the hack saw -

-

What did you do in the shop today?

M.J.Lampert replied to Mark Ling's topic in Blacksmithing, General Discussion

Goods, I've done that lots with wood or nonferrous and thought of that but the fact that all the calipers are technically my fathers, and I want to be allowed to stay in the shop makes me warry of doing it on much more Arthur that looks nice now if only stock was cheap enough a penny nail could actually be made for a penny in Canada, actually if only we still had penny's... just looked we are now over ten years without pennies up here M.J.Lampert -

What did you do in the shop today?

M.J.Lampert replied to Mark Ling's topic in Blacksmithing, General Discussion

working on getting a bunch of split crosses made, and wondering what the best way to mark the middle is I found it tales me more time to mark them than to spread and texture after their cut -

my projects/rambling/ other (pic heavy)

M.J.Lampert replied to M.J.Lampert's topic in Member Projects

3/8 I think I might see about finding some 1/4 for in the future -

my projects/rambling/ other (pic heavy)

M.J.Lampert replied to M.J.Lampert's topic in Member Projects

Happy new year to all, so I decided to try at least 1-2 new idea every month in the shop this year, so here is my first attempt at a split cross M.J.Lampert -

Les L, that is a nice stamp Thomas, wonderful to hear you are back were you should be was given this beauty by my mother, it used to belong to a close familly friend who passed away a few years back M.J.Lampert

-

iron dragon I immediately thought of that when i saw how he was holding it but its not quite bulky enough on the backside more to the size of the 1919 M.J.Lampert

-

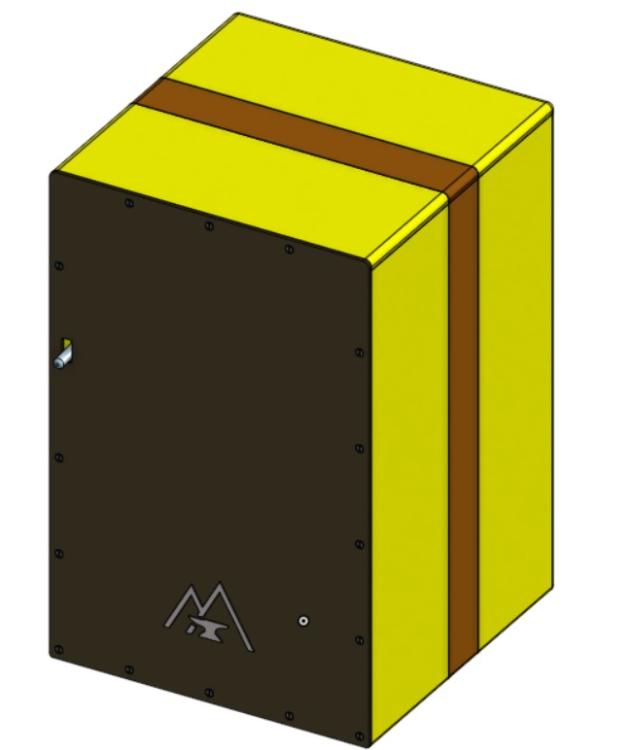

so I decided to start a page to compile my projects in one place now for what I'm working on currently: A Cajon for those who don't know a Cajon (Spanish: box) is a wooden percussion instrument that consists of 5 sides 1/2in. to 3/4in. of plywood or solid boards and the 6th is a thin (3/32-3/16) sheet of plywood this one should come to a final dimensions of 12.5x12.5x19 inches the wood is maple and walnut 3/4in. with a piece of pine plywood for the bottom side. The front is going to be 1/8th birch plywood M.J.Lampert

-

What did you do in the shop today?

M.J.Lampert replied to Mark Ling's topic in Blacksmithing, General Discussion

wonderful work all, so yesterday (Tuesday) we hit a low of -46C (-51F) now on monday they are calling for about +5C(41F) so over 50(90) degrees difference in under a week stay warm and keep the rigs plugged in M.J.Lampert ps i have a project with wood on the go wondering where I should put a thread on that i was thinking everything else if a mod wants to correct me please do -

What did you do in the shop today?

M.J.Lampert replied to Mark Ling's topic in Blacksmithing, General Discussion

didn't do anything in the shop today as it was -40 (very very cold for those who live in warm places) and only barely warmed up a little above -30(just very cold) hopefully towards the end of the week they say it will warm up M.J.Lampert -

glad their letting you out Thomas

-

I need to tweak it some before I post it (i have 2 medium zip locks of habaneros in the freezer to make more with) then im gonna post a bunch of recipes I did this year

-

1095 blade banana'ing

M.J.Lampert replied to M.J.Lampert's topic in Heat Treating Knives, Blades etc

if i try shim the blade when tempering should i go till its straight or just past? -

I made a wild blueberry-habanero sauce that goes good on eggs (my 5 year old brother agrees) if you ever come down from your frozen wasteland I might be convinced share M.J.Lampert

-

One job i took burning brush piles we went into a block (area the company had logging) and had to turn around because the air filter was stuffed with snow, and we wouldn't be able to get through the 2ft of snow with the 4-wheeler we had along so we turned around and went to a lodge the company had connections to so we could thaw the filter

-

Scott, that's similar to south vs north BC. In Vancouver they had 4-6 inches and have lots of trouble, crashes, people stranded, etc., here I know people who run little cars through drifts to get to work. i think it mainly boils down to how you were trained if you did all your learning and tests in fair weather, you will have trouble if you run into bad weather.

-

Frazer's Corner of the Internet [photo heavy]

M.J.Lampert replied to Frazer's topic in Member Projects

love it!! what's the handle material? -

1095 blade banana'ing

M.J.Lampert replied to M.J.Lampert's topic in Heat Treating Knives, Blades etc

Velegski : I hadn't thought of that because on both sides there were cold steel it would even out but thinking now there is a few seconds between the anvil side and the plate side cooling i may take a few of your ideasuse some 2x4s warm them up, then use them in the vice to apply even clamping. let me know if there would be any big problems with this first things first though, wait for warmer weather -

looks nice

-

welcome aboard from central British Columbia, make sure to READ THIS FIRST this covers most all our rules in one place check out United States - I Forge Iron to find a group near you make sure to listen to Thomas, Frosty, Latticino, George.N.M and the others with their knowledge, 98% of the time they know what there saying the other 2% they still have good ideas. M.J.Lampert

-

1095 blade banana'ing

M.J.Lampert replied to M.J.Lampert's topic in Heat Treating Knives, Blades etc

ARG, fat fingers and a slow mind. .08 and.03 respectivly -

1095 blade banana'ing

M.J.Lampert replied to M.J.Lampert's topic in Heat Treating Knives, Blades etc

the average on the spine is .8 the edge is at about .3in -

1095 blade banana'ing

M.J.Lampert replied to M.J.Lampert's topic in Heat Treating Knives, Blades etc

No, it's not a tempo I had heard that Parks 50 was good from above freezing to 160 so I figured to just make sure it was above freezing i waited for a warm day (above -10C) to reduce the amount needed to heat it I might try to shim and clamp the blade when tempering if not i will start over again a good point i realized from Frazer was that my anvil and block of steel where cold so any remaining heat to help straighten would be drawn out as soon as they come in contact M.J.Lampert