-

Posts

330 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by HammerMonkey

-

8 - 5' 4" long sticks of .25"x1.5"x1.5" angle iron, a 6" wide x 8' long heavy channel, a long chunk of 3/8" round stock, and an old 10 lb Sledge hammer, all from Facebook marketplace sellers near me. $20 all told.. fun day! I'm still looking for some old ball peen hammers to make texture tools ala JHCC, and some I beam for my future press project.

-

I like it! I wish I could do this type of drawing on the computer to help me figure out all of my dimensions and materials. Your design is pretty much exactly what I am wanting to build. With the exception of the hydraulic ram size. The ram I have is 4” bore x 28” stroke. The retracted length of the ram is 38.25” (pin C/L to pin C/L). I only plan to use 10” of the available stroke though. This would make the extended length of the ram 48.25”. I hope this won’t make the press too tall, or put the lower anvil too low to work comfortably.

-

I think you are onto something there Charles. I’d like to see how that would turn out.

-

Truth ^^^ Have you checked the Hengest and Horsa leather aprons? They are in Swaffham, UK and have an Etsy page. I have their original smith’s apron. It was north of $250 USD when I bought it, but seems to be discontinued at this time. If you google HengestandHorsa or the description below, you will see that they do have this one for sale now: Leather Smith's Apron - The Artisan - 'Grenewer' - Greenman $654.64 USD it is just too beautiful to wear while forging though..

-

Duracast Steel 150 Anvil

HammerMonkey replied to Wethepeople762's topic in Anvils, Swage Blocks, and Mandrels

In my earlier post, I was questioning if the smaller black anvil, on top of the rusty one, might be an arm and hammer. It almost looks like a hammer and part of an arm stamped into it. But I’m looking at it on a pretty small screen. -

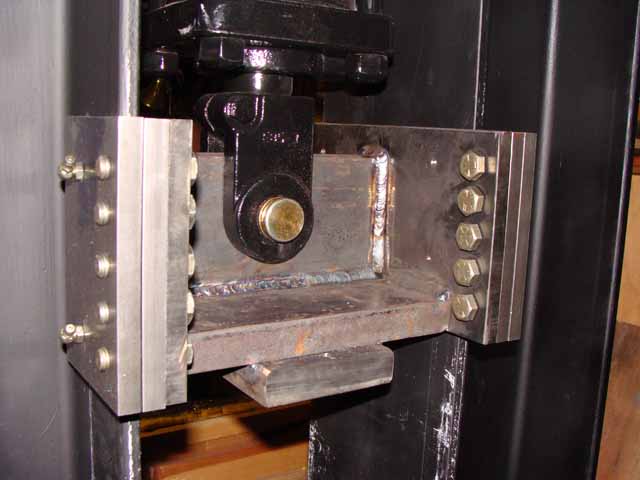

Eric Fleming describes his build on another forum in a post titled WIP - Hydraulic Press Build (you can Google it). i like his design for the guides.

-

Duracast Steel 150 Anvil

HammerMonkey replied to Wethepeople762's topic in Anvils, Swage Blocks, and Mandrels

It may be a trick of the eye, but it seems rather large for 150 lbs. Could it be kilos? I wonder how much the smaller (Arm and Hammer?) behind it weighs? Is it for sale as well? -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

Beautiful Aus! Truth!!! I am constantly inspired here. I will keep practicing and I just hope that one day my level of skill, and my execution will approach that of you guys so I can make something so beautiful. Thank you my friend -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

Happy birthday Das! And congrats on the the success with the heat treat. I think that anvil tool would come in handy working smaller stock and pieces like the little heart I made.. hmm you've inspired me again! -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Das! -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

After work I hustled out to the forge and made a little valentine trinket for my sweetheart out of some 1/8” round stock I have (I totally forgot what day it was and had to scramble ). She got a cord and made it into a pendant. I know it’s a very simple thing, but she really likes it when I make her something like this. -

Cable Damascus Bowie, With a Hammon?

HammerMonkey replied to jmccustomknives's topic in Knife Making

Outstanding! Awesome in every aspect. -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work sfeile. I like that hot cut tool. Inspiration! -

Forging a Teacher's Key Ring

HammerMonkey replied to bajajoaquin's topic in Blacksmithing, General Discussion

Truth!! I made a little leaf key fob for my wife that hooks over the edge of her purse, to keep her keys handy. While she thought it was beautiful, she mentioned how heavy it was on several occasions over the course of a couple of weeks... finally, she must have developed enough muscle to lug that chunk of iron around... no more comments about it, other than her friends and coworkers all want one now.. -

If you continue to wear a glove, I wouldn’t recommend duct taping it on... there are times when getting the glove off really fast is necessary...

-

2 X What they said^^^ The back story brings another dimensional aspect to his beautiful piece. Form and function are important, but presentation certainly enhances/enriches the experiance. Just as good food is not just about flavor. Presentation is such an important part of any creative experience. Stunning!

-

-

There’s nothing like a good joke! (And I’d have to say... most of the puns I’ve seen here are nothing like a good joke...)

-

Two more window knives and a kukri with book micarta

HammerMonkey replied to TheoRockNazz's topic in Knife Making

Very nice pieces... I REALLY dig the kukri! The book micarta looks like fossilized bone and The fullers are just perfect in shape and proportion. Beautiful work Theo! -

That is simply stunning. Well done sir!

-

Nice clean design. I agree with Marc1 and the iron dwarf on top/bottom beam orientation and gussets/corner webs for strengthening and the necessity of lots of high quality welding. What is the bore and stroke of yout ram? How tall will the base be that it sits on? How many tons of pressure are you designing for? i wish I had Cad Cam skills... sure makes it easy to see what you want to do.

-

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

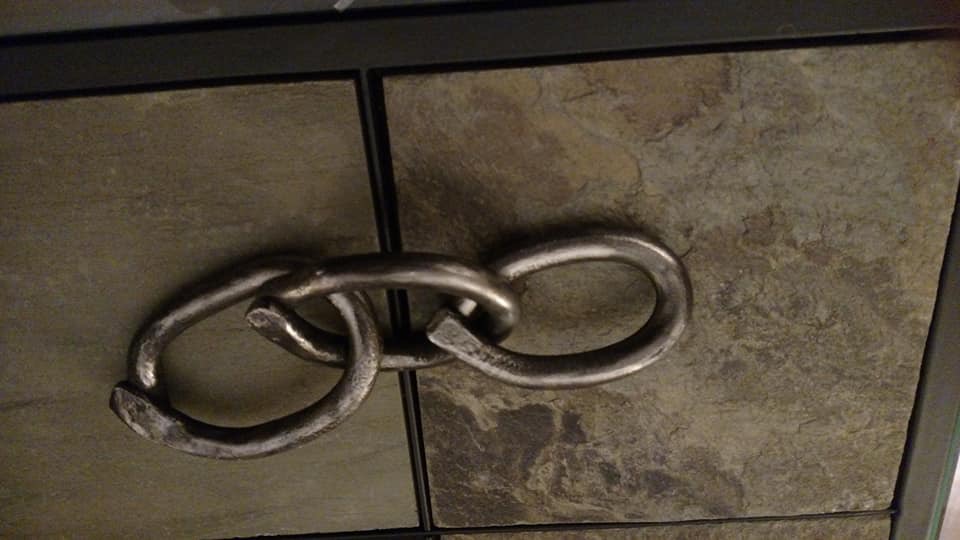

My friend (4Elements) came over today and brought his new homemade side blast charcoal forge with him. We fired it up and tried some forge welding. It is really an awesome setup and it works great! Then we fired up my bottom blast charcoal forge and tuned it up a bit. It actually worked really well too. I knocked out a rustic little flux spoon first, then forge welded three links together to make a little practice chain. It was a nice day to be forging out of doors and it was great spending time with a good friend and a skilled mentor. I am mostly self taught and the chance to work with someone who is experienced is golden. Thanks Byron! -

Joel, Very simple, clean and yet so expressive. I agree about your dog’s heads with their definition and character. I dig em! Will the bottle cap come in contact with the wall while being pried off? If so, maybe a backing plate could be added to protect it?