-

Posts

330 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by HammerMonkey

-

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

Yeah Aus... those pics of your awesome scrap pile are simply blacksmith porn.. -

Rail - evidence of heat treat?

HammerMonkey replied to Michael Cochran's topic in Heat Treating, general discussion

It almost looks like it is work hardened. I don’t know if that is a process used on steel rails though. -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Wouldn’t the comment from the spec for this cylinder (above) imply that pressure is reduced by some amount after the first 16” of stroke? If this is so, wouldn’t the tonnage produced be reduced as well? Albeit, the reduction may be insignificant, as genesaika suggests.

-

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

Two flap grinding disks, mounted back to back? Evidently, one spins the wrong direction then. Has that caused any issues? I’d be concerned about the grinding flaps lifting and catching/grabbing the work out of your hand. -

Thanks, then that actually allows 14” of stroke which is not bad for handled tooling and big stock..

-

Yes, the paint is scuffed up a bit from transport, but it is newly manufactured and never used. A local heavy equipment manufacturer buys sone type of component that comes with this cylinder attached. They remove and replace them with a different sized cylinder before attaching the component to the machine they are fabricating. I guess they get several of these in each year. My fried works there and offered me one when I told him what I’d like to do. Pretty good deal as this ram retails for about $400. the specs say: 3000 PSI 4” bore 2” rod 28” stroke Skived, honed tubing Heavy duty welded construction Chromed, ground and polished piston rod will operate at full pressure through 16 inch stroke Cast iron piston, cast steel butt, gland and clevis Loaded u-seal and urethane wiper gland, u-seal piston Stroke control may be installed on 8 inch strokes i am not sure what that all means. Does the 16” stroke comment mean that after the first 16” of extension, the power of the ram is reduced?file

-

-

Thanks CMS, that’s the info I was looking for (and what I hoped to hear).

-

I will try to get a picture tomorrow. Thanks

-

Internally?, or are you talking about on the exterior of the ram? ‘This cylinder has nothing attached to the ports at this time.

-

I believe this is a dual action cylinder. It has a port at each end (to drive the shaft out and in?). Yes indeed, I intend to build it with guards to protect me from high pressure failures. I work around hydraulic systems on large commercial aircraft and have seen the damage a pinhole leak in a high pressure hydraulic system will do to human flesh... The ram is brand new. Do you think it needs servicing or inspection? It looks pristine on the outside. Many hydraulic presses are designed with the cylinder/s on the bottom, to press upwards as you suggest. I personally have never cared for that design. I’d rather have my work resting on a stable, unmoving anvil, with the ram moving downward to make contact with the work. Thank you for your insight!

-

The left hand holds a sign that says "Sinister Smith"?

-

I just spent yesterday afternoon with a friend that struggles with depression too. It's hard to watch someone go through this, but close watching and paying attention to warning signs is what good friends need to do. Thoughts and prayers going out.

-

Yesterday I was gifted a brand new 4" bore, USA made hydraulic cylinder, by a friend. it has a 2" dia rod and a 28" stroke. it is rated for 3000 or 3500 psi (my CRS is kicking in). A 28" stroke is longer than one on any other press I could find. Someday I think I'd like to build a H frame hydraulic forging press for making hammers & Damascus billets, etc. I have been researching on the web, but there is not a lot about the maximum length of stoke. However, I did learn that the longer stroke should not reduce the power, or speed (IPS), other than it takes longer to travel the full stroke. Then there is the size consideration too as the height of the H frame would have to accommodate the longer stroke (so I wouldn't have my lower die positioned at knee level...). And I am sure that a taller press frame would need to be extra stout to resist flexing. If I were to use this ram with a 15 GPM pump I calculate that my extend speed should be about 4.6 in/sec and retract speed 6.1 in/sec. And a 11 GPM pump would net me 3.4 and 4.5 in/sec respectively. At 3000 PSI the pressing force would be a little shy of 19 tons. After a lot of digging, I could not find some answers though. 1. Does a hydraulic cylinder have to cycle fully each time it changes direction? A fast ram speed would be wasted if it had to go all the way in and out each time I pressed on something... 2. If so, could this be alleviated with plumbing design (switches/valves/etc?) 3. Does the longer extension dimension pose a greater danger of catastrophic failure of the shaft or other components under load? I would think that if I didn't exceed the PSI rating, the ram would operate within its design capacity, but... it does seem a little scary! 4. Are there any other considerations I am missing? I am thinking that this ram may work out if I can design & build a suitable frame for it. Any thoughts and opinions are welcome. Thanks

-

Just a Tub of Dirt, photo heavy

HammerMonkey replied to 4elements's topic in JABOD - Just A Box Of Dirt

Nice job Byron! I really like the design. I want to stop by and see it in action when you get it set up and working! -

Not multiple forges... I think that could run EVERY forge!!!

-

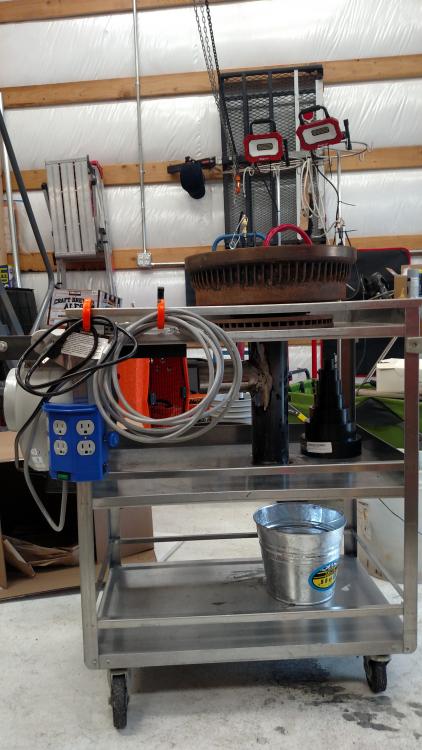

My wife is a surgical nurse. She got some stainless steel carts and tables from surplus. This is what I use for my gas forge. And what I use for my charcoal brake drum forge.

-

That is awesome 58!

-

Beautiful knife. Unfortunate about the weld, but still a very lovely piece.

-

Heart Sculpture for Valentines

HammerMonkey replied to tdriack's topic in Metal Sculpture & Carvings

Very cool Tdriack! I am sure she will love it. -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Das. Appreciated! I will get it right next try.... or the next one... or after that perhaps. -

What did you do in the shop today?

HammerMonkey replied to Mark Ling's topic in Blacksmithing, General Discussion

I made an Ulu. It's my third attempt at this type of blade, and it's the closest I've come to success... Everything went great until I got to final sharpening... Then I saw the fine little crack in the blade. I stopped at that point. If I'm going to keep it and use it with the little crack, I still need to finish the final polish and clean off the rouge that's covering the blade. Kinda bummed as the forging, hear treat, tempering, and the handle making/riveting all seemed to go do well.. -

Why blacksmithing? initial pull

HammerMonkey replied to Tock's topic in Blacksmithing, General Discussion

My father collected knives. He developed the interest when he was a boy, as his father also collected them. When Dad passed away 5 years ago, I received his collection, which included many knives from my grandfather's collection as well. I never had much interest in knives before this. They made me kinda nervous. Heck... paper cuts freaked me out. I could only imagine cutting a finger off with a big Bowie knife or meat cleaver... Lol. However, there were so many beautiful pieces that I had never known he had. As I held and examined each of them I became enthralled with the detail and craftsmanship, along with the power and utility of these beautiful tools. I found that I really understood his connection with the knives, and I knew that shared it too. I started to think about my abilities and if I could ever craft anything such beauty and utility. My first thought was... No way! I have never been able to draw, paint, sing, dance or do anything much in the way of an artistic expression. However, I remembered that when I was young I carved little figures out of sandstone and wood. Apparently they were good enough to get some attention from the adults in my life. My parents proudly showed them to their friends and I received several commissions to make items for some of them. It made me think that perhaps I might have a small measure of talent in three dimensional artistic expression. I thought "knives and other products of the blacksmith are 3 dimensional! Maybe I could do this". So started teaching myself to forge things a few years back. I am still a very green novice and only in the last year I've discovered this forum, which has helped me get on track in many areas where I started off on the wrong path. The good news is that the few things I have successfully turned out have made me believe that I actually may have a few molecules of talent bouncing around in my head. And if I keep at it, they may organize themselves enough to help me make some things that others would like. Fingers crossed! -

Thought you all might appreciate this...

HammerMonkey replied to KILLERkroopa's topic in Blacksmithing, General Discussion

Ok, I’ll ask.. what is it? I thought perhaps it was a scale?