-

Posts

954 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jasent

-

Show me your anvil stands

Jasent replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Loving these stands! Keep them coming. This is my old setup and a poor pic of the current stand for my rail "anvil" -

I was thinking 90, I can always go larger later if needed but it's not so easy to go smaller. Maybe I'll just improve the one on my striking "anvil" for now and see how it goes. I think it's time to start working on a stand. Using this thing will tell me a lot more about what I need. I want a metal stand, I do have some monster RR ties (12"-16") and telephone pole but currently I can cut steel much easier than wood. Jhcc I did see that stand and like the idea but it does not look very sturdy. I don't want my "anvil" to be able to bounce around or move in the stand I may modify it for my needs though the block of steel weighs as much as me. 260lbs Thanks for the input guys i still have my heart set on a papa Rhino just not in the cards this summer.

-

I've done sound proofing in a home library. We used insulation for 2x6 walls in 2x4 walls. it worked very well

-

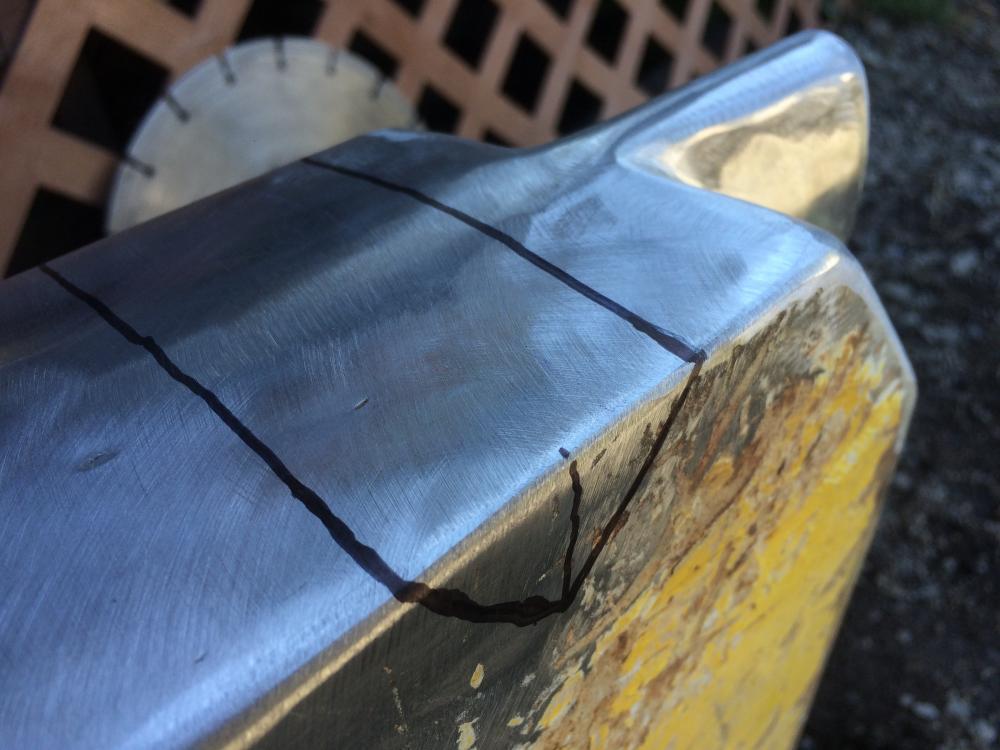

I'm likening the hole threw idea. I've gotten a section about 5" fairly flat tapering to a mild hump. With my rail anvil I learned a mild hump can be helpful. I've radiused my edges from small to large. Ive marked out my v notch to the size I'm wanting. I have this notch a little smaller in my striking plate and like it but wanted deeper and wider. The fuller I put off to one side a bit to have one side more open for hammer clearance as I can see that angle being useful.

-

Your telling me but I'm also learning a lot from this project. I think I need some handles of some sort though. This thing is heavy and tough to move around. May weld a bit of chain on each side to use the engine hoist to lift it. Sofar I think I want a v notch near the fuller and then I'll leave it alone till I know more what I need. I'm curious how much different this will be over my rail "anvil"

-

Show me your anvil stands

Jasent replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

I notice your forge is lower than your anvil face. Is this on purpose? -

Thank you Thomas . I'm looking forward to putting it to work

-

-

-

Correct. There is no hurrie. I some times get ahead of my self.

-

I was thinking of that too but just don't know enough to know what other shapes I might need. Got any ideas on shapes I could include? Thought I would do the sides like a swage block with negative curves or dishes. Any and all tips/ advice is appreciated!

-

Shop door handle pulls inspired by Chandler Dickinson

Jasent replied to Stitch's topic in Blacksmithing, General Discussion

Great job. I may try these my self. I enjoy watching Chandler as well -

Show me your anvil stands

Jasent replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

What are those things on the right side of the anvil? -

Show me your anvil stands

Jasent replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

With so many anvil threads there has got to be a million stands out there holding up these anvils. Found many stand threads but I thought we need a place to talk about anvil stands only. A place where people can get or share their ideas on stands and can easily be found in one spot. All tips or ideas welcomed! Thank you for sharing -

Yes a harbor freight 4.5" I had a dewalt 7" but some jerk figured they needed it more than I did. I've been searching threw the forum looking at every stand I can find getting ideas for this block. I'm not sure yet how I'll secure it in the stand. I love the widow stand jlp made with the utility hitches for trays or what not.

-

Thank you for bringing that up I've spent a little time with a 9". You know you need to be careful when you kick it on and the torque makes it turn in your hands. I'll be very careful. I'm in no rush as I have an "anvil" like object to use for now. It's not much but it's all I've ever know

-

My uncle just stopped by and said he has a 9" grinder I can use. That should help ally! And not burn up my HF 4.5"

-

Well @Frosty 's advice is working much better. 26grit stone. First pic is about 10 min 2nd is about 20 min, that's counting breaks. Grind for a few then let grinder cool for a min then grind. Thanks again

-

Thank you. I just love your ways of explaining things. For the record I don't watch fif

-

That's pretty much my plans lbs. i thought it was mild steel. Figured 36 grit would eat up those torch grooves quick. I was wrong. I'll try the hard stone and see how it goes.

-

Got a little time yesterday and began cleaning up my block of steel. I don't know what this steel is but it is tough to grind. Going to take a lot more grinding to smooth and flatten the face. Staring with a 36 grit flap disk for almost an hour. Angle grinder started getting hot so I gave it a brake. Still brain storming my stand

-

I know you know frosty. Just adding to his reading list

- 21 replies

-

- mixing tube

- propane

-

(and 1 more)

Tagged with:

-

Have you looked into a ribbon burner?

- 21 replies

-

- mixing tube

- propane

-

(and 1 more)

Tagged with:

-

I like it. Would be a great bottle opener to finish it off

-

This is all my blacksmithing tools any advice or suggestions

Jasent replied to Boedie's topic in Tools, general discussion

When I first started I had a 4 1/2" angle grinder. A framing hammer I ground the teeth off the face and a pair of pliers and a small coffee can foge made very wrong. It got me pounding steel and got me hooked. I learned from there. Use what you got and pound some steel. The Rest will come with experience. Heck you may find its more work than play and decide it's not for you.- 27 replies

-

- blacksmith

- blacksmithing

- (and 6 more)