-

Posts

1,180 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Lou L

-

I would suggest that believers try testing a sensitive compass in their shop first. If they can get it to point true north while inside the shop then they have a basis for experimenting. My guess is that the power in the walls, metal framing, corner and edge bead in the walls, the welder, etc...have a much larger impact on the compass than the Earth’s magnetic field. That being that case, I have high skepticism about the North quench theory.

-

Congrats Das, all the hammering in the world and you’ll never have a better creation. Now you know “that feeling” the first time you saw her. Weirdest and best feeling (and most overwhelming) I’ve ever had. Every dad I’ve talked to has said the same. Some great advice to be had has been shared already. The ear protection is key. Remember that her voice actually has the power to cause chemical change in mom...endorphins release, etc... It’s those high pitch ones that really get you. I wish I read Thomas’s advice when I was in your position. My wife and I suffered with our first due to silent reflux. The bit about sign language is dead on. I wa shocked when my daughter asked for more food using sign when she was maybe 7-8 months. She had the power to tell us basic things and it made a huge difference. Baby sign language is real!

-

My plan was to build your NARB design for use and then make a second one for playing/experimenting. In fact, I will likely make the test one first just to get the process down. Question: If I add a “Y” and then a 3” nipple to form the mixing tube, do you think that the added volume in the “Y” even when sealed off, would affect the output of the burner? I will likely start by putting a gate on the “Y” to experiment with being able to control minute increases in air volume. Then I may try blowing forced air in based on the results. Either way, I assume you are dead right and I’m on a fool’s errand. But, I’m going to learn a lot about burners in the process...I hope.

-

What weird animals have been in your shop

Lou L replied to Glenn's topic in Blacksmithing, General Discussion

He makes for a handsome custodian for your shop. -

Really cool idea. Let me try to predict another minor possible problem that could occur during use. If you are cutting through thicker stock the angle of the swing arm will change slightly as it pivots on the support. This could cause the cut you are making to drift slightly toward the direction of the hardy. To keep it completely straight the pinch point of the chisel would have to swivel independently of the swing arm. Until you get this design down I think I’ll just continue with my practice of taping a bubble level to my top tools

-

Okay, I’m basically a kid in little league stepping up to the plate at the World Series right now...but I aim to do some experimentation and learn on the way. I have been reading through the entirety of gas forges 101 and taking notes and have already read this thread and a number of others (at least ten) trying to collect information. After deciding that I want to build this burner design I considered an odd possibility. I have a small 100 CFM lower with relatively low static pressure sitting around doing nothing. I think to myself, “Would it be possible to supercharge this burner by adding an air assist?” Then I run into a comment by Mikey suggesting the same thing and I tweak a little. I imagine that the lower pressure may not add the need for a diffuser but it may. That aside, if I were to experiment with this idea, where would be the best place to introduce the air? My first thought is to add a “Y” connection about two inches below the mig tip in the mixing tube. Then I imagine pumping air through copper tubing that enters through the current air intakes. Is this idea complete nonsense? Would the increase in air necessarily increase the LP consumption or can you increase air and maintian lower pressures from the propane tank? Basically, I want to get a basis to determine whether or not I would be tilting at windmills here. Lou

-

Welcome aboard Scotty. There are a number of easy methods of making a simple forge like this. Before you even start, though, get yourself up to speed on this forum. First, read this thread so you can avoid all the simple issues people have when they join: https://www.iforgeiron.com/topic/53873-read-this-first/ All the sticky threads in the solid fuel forge section will help: https://www.iforgeiron.com/forum/64-solid-fuel-forges/ A video showing how simply this style of forge can be created recently gained some love here on IFI. This is one of the YouTube channels that you should watch to learn about blacksmithing.

-

It’s fate I guess, because Black Bear Forge just posted a video yesterday or the day before talking about this topic. He suggested people SPAM his comment section with suggestions for other good channels. It was telling that his viewers appear to be “in the know” for the most part because their suggestions were mostly highly credible. jlpservicesinc's Channel was suggested by more than one person. Many suggested that young man in England whose videos have become much less instructive and more about entertainment. Though, he does good work talking constantly about safety and PPE...so he does have value. What it comes down to is that, on YouTube, if you want to get lots of traffic you have to make knives on a blacksmithing channel. Torbjörn Åhman is one of the few exceptions. A number of people regularly comment that they don’t even understand what he is doing but they find themselves mesmerized and “at peace” watching him work in silence. His nature scenes he shows during breaks while a piece is annealing help out with the calm vibe of his videos. He really belongs on PBS. I think I’m going to watch one of his videos now, before I go to bed!

-

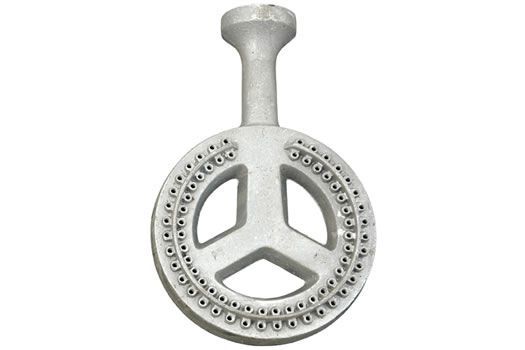

Got it. Venturi is the process...inducer is the port at the end of a tube? Either way, I was thinking I could drill holes in the side of the forge for each outlet nozzle on the burner so it can be mounted outside the forge. Use the crayons, etc... But I was concerned that the relatively short flames it produces wouldn’t be able to make their way past the 2” of Kaowool and the 1/2” of castable. If I ditch the wool I feel like I’d have an inefficient gas hog. It’s still an idea that grabs my attention every time I start up that grill and the burners sound like a jet with pure blue flames. In open air they get the 1/4” grill grates glowing red. This is the burner (comes with 3 on a grill): It just seems like the work required to implement this would be better spent on a NARB.

-

, It is to one Venturi...it is three small ones (one for each burner). I was think8ng I could put thin rods into each nozzlette on the burner, apply castable, and then yank them when it dries. My main problem is that the burners are round and I can’t visualize how I would insulate the center of them. Seriously, though, I am somewhat dead set on building your NARB design ...or paying you to make me one and ship it to the lower 48..<wink wink>

-

I was actually thinking about doing this with the burners from my Camp Chef grill. It has three burners that operate on a Venturi. Each burner produces 30,000 BTU. In trying t9 figure out how I would protect the burner with refractory I decided it would just be easier to make a NARB. Still an interesting idea.

-

What did you do in the shop today?

Lou L replied to Mark Ling's topic in Blacksmithing, General Discussion

That was the last video posted by Torbjörn Åhman I posted a few days ago. The link is in the stickies JABOD thread. -

What did you do in the shop today?

Lou L replied to Mark Ling's topic in Blacksmithing, General Discussion

Wow. That forge is sweet! I can’t wait to see it fired up. I’m rather envious and, although I enjoy working with it, I’m feeling bad for my forge. Still, I have a major redesign planned for it. Only thing is, I’m pretty dead set on building a Frosty NARB and the forge to go with it. I’ve decided that I need both propane and coal forges available to me. I’m seriously not looking forward to figuring out how to cure the castable in a warm 100% humidity environment. That’s go me stumped considering the cold Spring we are having. Anyway, enough of my issues. That Forge is stellar.... -

rockstar.esq, I honestly couldn’t agree with you more. There are severe limitations to the teaching potential in YouTube. It is entirely passive learning. Prior to the Industrial Revolution, most people learned hands on, as an apprentice at “something”. (I know I’m generalizing). Since then, schools were designed to House the growing population and prepare them. As society advanced, more youth required education in a school and fewer were entering apprenticeships. Now, all children in our society go to school and learn passively. They are ALL prepared for the same few college tracks. Every student in America, essentially, is being prepared to go to a four year liberal arts college. We are practicing the exact model of education, with very little alteration, that we did 200 years ago. If a high school student’s education was work-based and supplemented in a classroom things would be different. They figured it out probably 3000 years ago and we have lost our way. We have created a concept called adolescence, tacked the label on teens, and decided that they were in societal limbo. They aren’t helpless children but they can’t be productive members of society yet either. 200 years ago most of them would already be shouldering some of the burden of helping the family survive. There is so much to it...the problem of how we teach the next generation is a complex lattice of issues. Still, in the context of blacksmithing (and a number of other skill sets) there is some value to learning on YouTube. Knowledge that is sought out aggressively is superior to that which is spoon fed to an apathetic subject. People who seek out information are more likely to actually practice it soon thereafter. Of course it would be ideal if they could work one on one with that person in the video. Even then, there is no guarantee that they could put aside their ego and allow their desire for mastery to win out (likely the problem of the younger electrician you worked with). I dont know why why it is so hard for us, as a society, to figure out how to teach people what and how they need. I don’t know why some people choose a career just to be mediocre in it. But I do know that the internet has made all of the knowledge (and misinformation) in the world available democratically. The purpose of this site (bestowed upon us by Glenn) includes the proliferation of information to benefit experienced smiths and to support new ones. I think we could consider it a duty to inform new smiths (myself included) about the quality of information presented on YouTube. It would be a service to the community and a real hoot for us to debate the qualities of the content.

-

Truer words have never been spoken. Being a teacher, I have years of empirical evidence to support your statement.

- 30 replies

-

- charcoal forge

- side blast

-

(and 1 more)

Tagged with:

-

Thanks. I was about to email him when I thought to ask you thinking it might be a quicker answer. I was being lazy and selfish

-

I second everything Das said. I hope you stay with us and keep sharing your experience and knowledge. An active mind is the key to happiness. My father in law is currently struggling with losing use of his legs due to nerve damage. He feels so sharp but just can’t walk or get around reliably even with a walker. He is struggling with it but he stays positive by doing the things he loves that are still within his body’s ability. Be well. Lou

-

Nice! I’d suggest you make about fifty more of those before you move on. I make a few leaf key fobs in the style I worked on with JHCC every forging session. I bang them out in down times or at the end when I’m done with my main project. Another thing to work on: you might want to work out your stem before you shape the leaf. I think it’s important to do the stem as well every time you do a leaf. I learned the hard way that there is a breaking point in terms of how thin you can make the stem where it meets the leaf before it becomes too fragile for further forging. Have fun either way!

-

What did you do in the shop today?

Lou L replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice...I’m envious. As an aside, the walls of your tuyere shroud are much thicker than mine. I built a bosh that can hold 20 gallons of water because everything I read said it was necessary. However, even with the thinner walls my water never boils and I only keep it about 1/3 full. You don’t need to make a huge bosh unless, of course, you plan on using it for making soup. -

If you get the chance could you measure the dies on the guillotine tool and let me know their dimensions? If they work with the thick leaf springs I have I just might buy that thing. Thanks! Lou

-

Just a box of dirt, or a simple side blast forge

Lou L replied to Charles R. Stevens's topic in JABOD - Just A Box Of Dirt

When I saw it I knew you had to see it! -

I’m planning on buying a few of his tools. His hot cut tool (and all of his top tools) is made out of h13. He lives in Taipei and is able to have them machined cheaply. He builds his tools with stock machined to his specs. Since I don’t have a power hammer but I want an H13 top cut, his for $30 or so is an attractive option when I consider the cost of the steel and my time.

-

What did you do in the shop today?

Lou L replied to Mark Ling's topic in Blacksmithing, General Discussion

What is the diameter of the hole in the faceplate? Mine is a bit too small at 5/8”. I have since learned that between 3/4” and 1” is better and matches traditional designs. -

It may be hubris of us, but I think it would be a worthwhile endeavor for members new and old to create an “acceptable instruction” list of YouTube channels on blacksmithing. We already have a list generated but perhaps it should be updated with a set of standards for the content. I, for one, would enjoy the discussion involved when members here debate the merits of channels. I’m not even certain if Black Bear Forge is on the current list but I know he is spectacular. His channel should be called “curmudgeon tube”. SEE....I just started the conversation by accident!

-

Frosty posted an excellent step by step on lining a forge that I thought was made a sticky not too long ago but I can’t find it right now. It would serve you well to hunt through Frosty’s posts in the gas forge section until you find it.